- Overview

- Product Parameters

- Feature box

- Application

Basic Info.

Forming Function

Filling, Seal

Driven Type

Electromagnetic Vibration + Pneumatic

Material Type

Solid

Packaging

Bag

Packaging Material

Plastic

Certification

CE,ISO

Material

All Stainless Steel

Control System

Mitsubishi PLC+English Touch Screen

Condition

New

Core Components

Motor, Pump, PLC

Weighing Speed

1-5bag/Min

Frequency/Voltage

50Hz/60Hz/220V,Three-Phase Five-Wire

Transport Package

Steel Frame + Wooden Box

Specification

1650*1000*2600mm

Origin

China

HS Code

842240009

Production Capacity

100 Units/Month

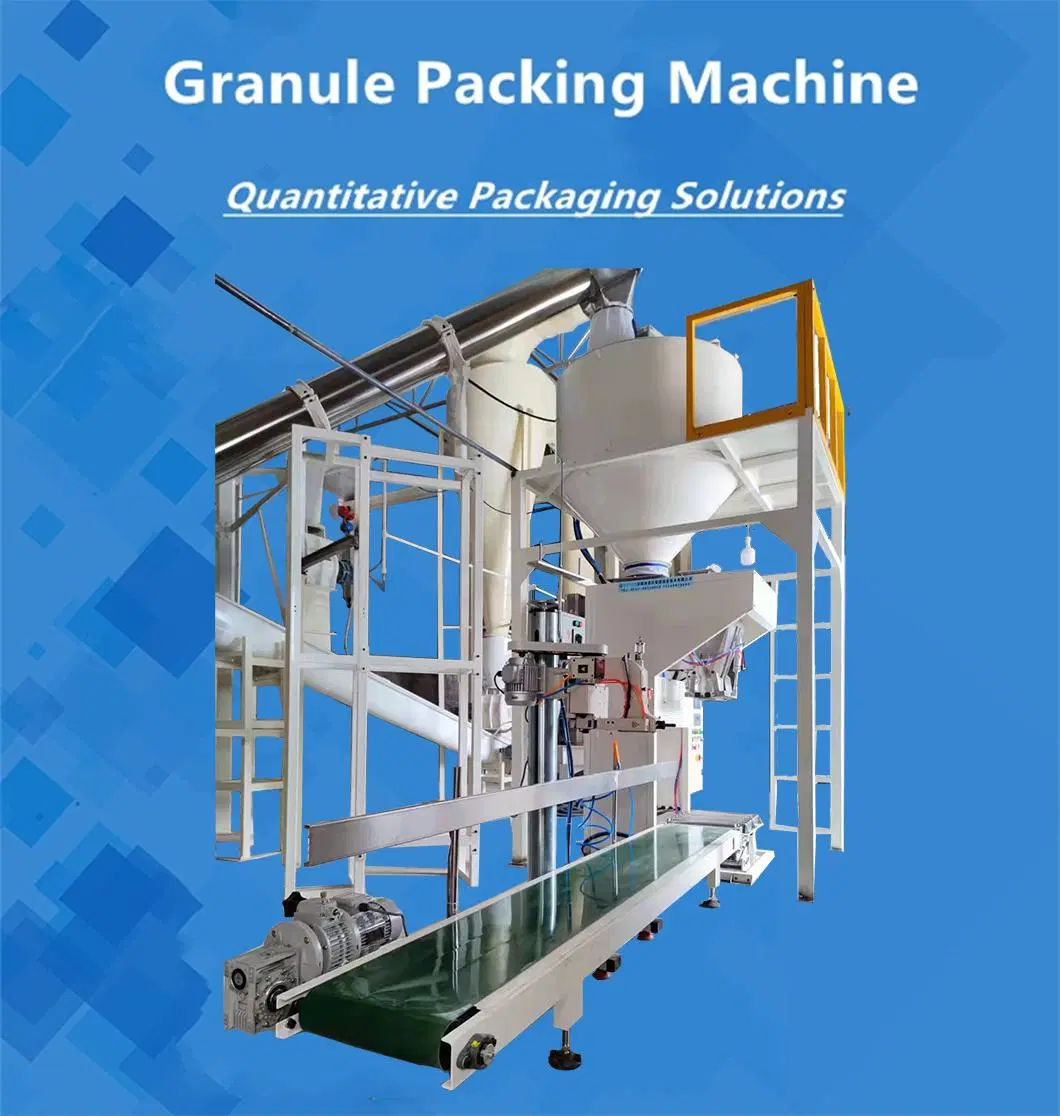

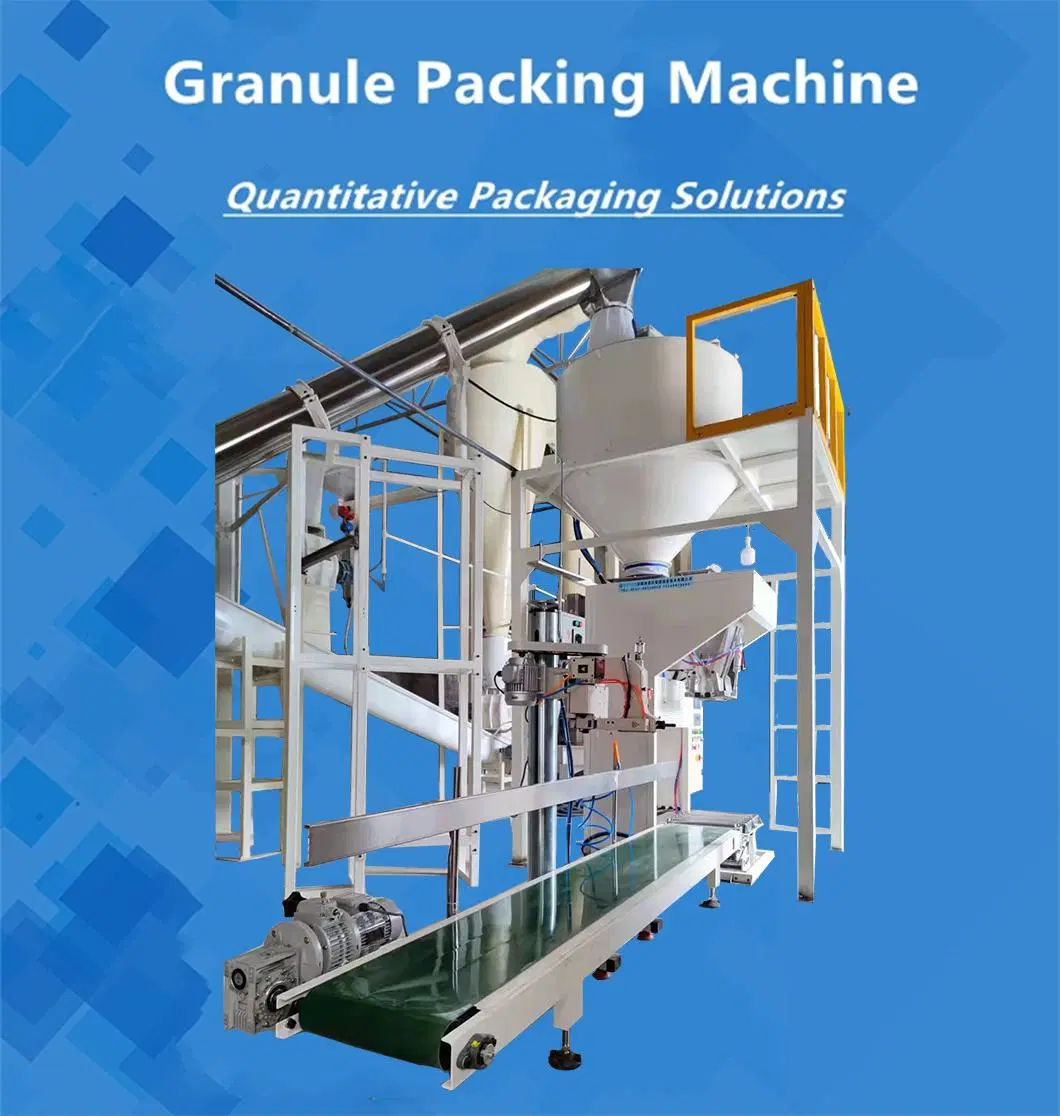

Product Description

Why Choose Us 1.15+ years factory

What we do for you:1. Machine can be customized according to the requirements of clients.

Product Description:

CD50M quantitative packaging machine is mainly composed of automatic weighing device, which can be combined with folding machine, sealing machine and conveyor to form semi-automatic packaging line. When using, you need to manually put the bag on, and then the machine will automatically weigh the material, and the weighed material will automatically fill the bag. After filling, the conveyor will transfer the bag to the folding machine, which will simultaneously fold and automatically seal. Finally, the carrier delivers the packed bags to the stacking location. The whole process only requires a worker to manually place the bags, and other work is done by the automatic quantitative packaging machine. Our company's automatic quantitative packaging machine packaging precision is high, packaging speed, high degree of automation, is a very practical powder packaging equipment, can improve packaging efficiency and accuracy, so that it can be widely used in chemical, metallurgy, minerals, light industry, agriculture, building materials and other fields, for a variety of granular materials quantitative packaging

2: The weighing control system is designed according to the requirements of IP54 (dustproof and waterproof);

3: The machine can be combined with an automatic feeding machine, conveyor, sewing machine and automatic control box to form a packaging unit;

4: Double buckets are used for weighing and measuring in turn, which is fast.

Advantage of Big Bag Fertilizer Bagging and Sealer Machine:

PLC control, easy to operate

High-precision electronic scale weighing, high precision

All stainless steel structure, easy to clean and corrosion resistant

Electronic screen or Chinese LCD touch screen for users to choose

Each scale is a two-stage feeding method, with high speed and high precision

FAQ

FAQ

1: Are you a factory or trading company?

A: As the pictures I show you in above, located in jining city,We mainly produce automatic bagging machine, automatic palletizing machine, vacuum packing machine, ton bag packing machine and some semi-automatic machine, at the same time we can also customize the production line according to your requirements.

2:What's the payment terms?

A: TT transfer,L/C and other payment methods if it is convenient for you.

3:What's the warranty of your equipment?

A:1 year warranty on the machine core after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support service in after-sales.We test every machine manually to make sure they are in good condition before they are sent to your place.

4:What is the service?

7 days 24 hours on line service,engineer overseas service is also available if necessary.

5:What's your advantage? Why we choose you?

A1: We have the most professional techniques and team, we are able to customiz machines according to the customer requirements,which is hardly acquired from other suppliers.

A2:We are a professional manufacturer and warmly welcome clients from worldwide to visit our factory and cooperate with us.

1.15+ years factory

2. Professional R&D Team

3. Customization service

4. 100% QC inspection before shipment

5. Certificate By CE & SGS

6. No third party, from the factory and the buyer to sell one to one

7. Good after-sales experience, provide videos of installation, online support and engineer overseas services.

8. At least one year warranty.

What we do for you:1. Machine can be customized according to the requirements of clients.

2. Your package sample can be freely test on our machine.

3. Provide business consulting and technical support, plus free professional filling solution.

4. Make a machine layout for clients based on clients' factories.

5. All the machine for 1 year quality warranty. Within a year, if there is any damage, spare parts will be sent to you free of charge.

6. Videos of installation; Online support; engineer overseas services.

Technical Parameters of Bagging sealing machine

| item | 5-50KG Powder Filling Bagging Machine |

| Packing Weight: | 5-50Kg |

| Packing Speed: | 3-6 bags/min |

| Packing Accuracy: | ±0.3% |

| Filling Method: | Auger(s) |

| Metering Method: | Fill-By-Weight |

| HMI: | LCD Touch Screen |

| Control System: | PLC |

| Air Pressure: | 0.4-0.6Mpa |

| Air Consumption: | 1 m3/h |

| Weighing Mode: | Sensor |

| Frequency/Voltage: | AC Three-Phase 380V 50Hz/60Hz |

| Power: | 2.2kw |

| Dimensions: | 3000*1500*2500mm |

Product Description:

CD50M quantitative packaging machine is mainly composed of automatic weighing device, which can be combined with folding machine, sealing machine and conveyor to form semi-automatic packaging line. When using, you need to manually put the bag on, and then the machine will automatically weigh the material, and the weighed material will automatically fill the bag. After filling, the conveyor will transfer the bag to the folding machine, which will simultaneously fold and automatically seal. Finally, the carrier delivers the packed bags to the stacking location. The whole process only requires a worker to manually place the bags, and other work is done by the automatic quantitative packaging machine. Our company's automatic quantitative packaging machine packaging precision is high, packaging speed, high degree of automation, is a very practical powder packaging equipment, can improve packaging efficiency and accuracy, so that it can be widely used in chemical, metallurgy, minerals, light industry, agriculture, building materials and other fields, for a variety of granular materials quantitative packaging

Features of Big Bag Fertilizer Bagging and Sealer Machine

1: The multi-stage feeding and feeding mechanism is adopted, and the weighing range is wide, which can ensure the speed and accuracy of the maximum and minimum weighing;2: The weighing control system is designed according to the requirements of IP54 (dustproof and waterproof);

3: The machine can be combined with an automatic feeding machine, conveyor, sewing machine and automatic control box to form a packaging unit;

4: Double buckets are used for weighing and measuring in turn, which is fast.

Advantage of Big Bag Fertilizer Bagging and Sealer Machine:

PLC control, easy to operate

High-precision electronic scale weighing, high precision

All stainless steel structure, easy to clean and corrosion resistant

Electronic screen or Chinese LCD touch screen for users to choose

Each scale is a two-stage feeding method, with high speed and high precision

FAQ

FAQ 1: Are you a factory or trading company?

A: As the pictures I show you in above, located in jining city,We mainly produce automatic bagging machine, automatic palletizing machine, vacuum packing machine, ton bag packing machine and some semi-automatic machine, at the same time we can also customize the production line according to your requirements.

2:What's the payment terms?

A: TT transfer,L/C and other payment methods if it is convenient for you.

3:What's the warranty of your equipment?

A:1 year warranty on the machine core after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support service in after-sales.We test every machine manually to make sure they are in good condition before they are sent to your place.

4:What is the service?

7 days 24 hours on line service,engineer overseas service is also available if necessary.

5:What's your advantage? Why we choose you?

A1: We have the most professional techniques and team, we are able to customiz machines according to the customer requirements,which is hardly acquired from other suppliers.

A2:We are a professional manufacturer and warmly welcome clients from worldwide to visit our factory and cooperate with us.