Basic Info.

Model NO.

PM-320F2

Material Type

Powder

Packaging

4 Side Seal Sachet Bag

Packaging Material

Film

Transport Package

Standard Wodden Case for Export

Specification

CE

Trademark

Alpha-Pack

Origin

Heyuan, China

HS Code

8422400000

Production Capacity

500pieces/Year

Product Description

4 Side Seal Sachet Packing Machine Application:

Automatic packaging of liquid, granule or powder in 4 side sealed sachet for the food, pharmaceutical, chemical and other industries.

Standard Feature:

1. The machine can automatically complete the products measuring, conveying and feeding, filling and bag forming, date code printing, bag sealing and cutting.

2. Servo motor driven heat seal film pulling system.

3. High sensitive fiber optic photo sensor can automatically trace color mark accurately.

4. PLC control system combined with touch screen, can easily set can change the packing parameters. Daily production output and self-diagnostic machine error can be viewed directly from the screen.

5. PID temperature controller monitors heat sealing temperature within ± 1 º C

Optional filling device:

1) Volumetric cup (sugar, salt, coffee, sesame, condiment, etc. )

2) Powder Auger filler (Coffee powder, milk powder, sugar powder, solid beverage, spice, etc. )

3) Rotary Gear Pump for Liquid (sauce, ketchup, mustard, mayonnaise, etc. )

4) Piston Pump for Liquid (liquid, cream, shampoo, conditioner, ketchup, etc. )

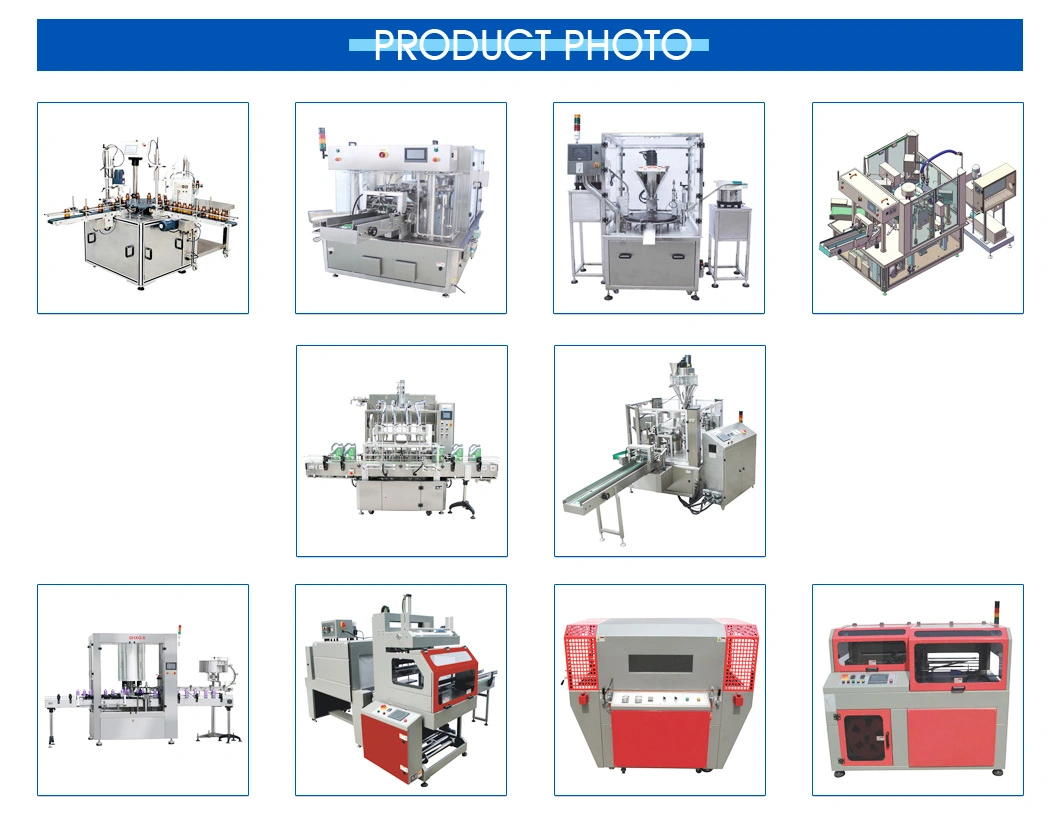

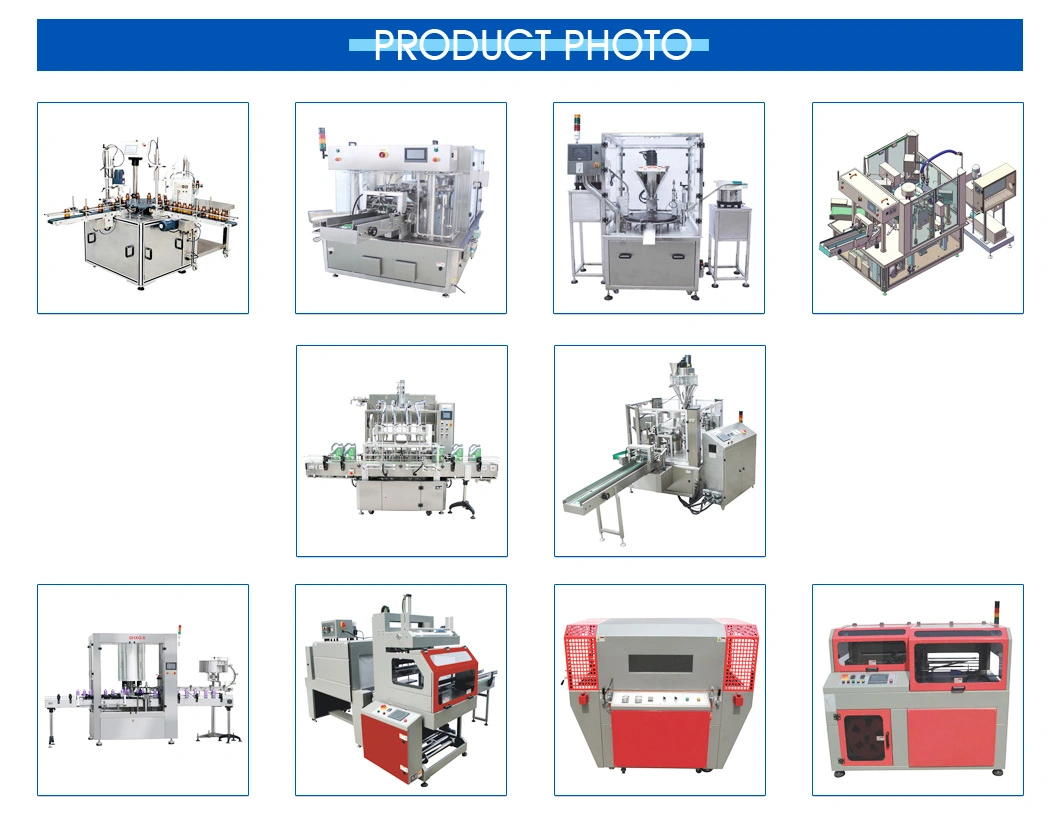

* In the photo, it shows model PM-320F equipped with auger screw filler for powder filling.

Automatic packaging of liquid, granule or powder in 4 side sealed sachet for the food, pharmaceutical, chemical and other industries.

Standard Feature:

1. The machine can automatically complete the products measuring, conveying and feeding, filling and bag forming, date code printing, bag sealing and cutting.

2. Servo motor driven heat seal film pulling system.

3. High sensitive fiber optic photo sensor can automatically trace color mark accurately.

4. PLC control system combined with touch screen, can easily set can change the packing parameters. Daily production output and self-diagnostic machine error can be viewed directly from the screen.

5. PID temperature controller monitors heat sealing temperature within ± 1 º C

Optional filling device:

1) Volumetric cup (sugar, salt, coffee, sesame, condiment, etc. )

2) Powder Auger filler (Coffee powder, milk powder, sugar powder, solid beverage, spice, etc. )

3) Rotary Gear Pump for Liquid (sauce, ketchup, mustard, mayonnaise, etc. )

4) Piston Pump for Liquid (liquid, cream, shampoo, conditioner, ketchup, etc. )

* In the photo, it shows model PM-320F equipped with auger screw filler for powder filling.

| Model No. | PM -320F | PM -320F /2 |

| Max. Measuring Range (ml) | 300 | 100 |

| Bag Length (mm) | 80-200 | 80-200 |

| Bag Width (mm) | 50-160 | 30-80 |

| Speed (Bag/min) | 15-40 | 30-80 |