Basic Info.

Model NO.

MG-1200

Forming Function

Forming, Seal

Driven Type

Pneumatic

Material Type

Liquid

Packaging

Pouch

Packaging Material

Film

Film Width

Max.1200mm

Bag Length

300-900mm

Bag Width

100-600mm

Diameter of Film Roll

Max.320mm

Packing Speed

5-10bag/Min

Measuring Range

8000ml

Film Thickness

0.04-0.12mm

Power

220V, 50/60Hz, 3kw

Machine Size(L*W*H)

1488*1080*1490mm

Machine Weight

About 1120kg

Air Supply

6-8 MPa

Bag

Hole Bag

Bags

Pillow Bag

Applications

Liquid

Liquid

Paste

Transport Package

Wooden Case Plywood

Specification

Max. 1200mm

Trademark

MOTECH

Origin

Shanghai

HS Code

8422303090

Production Capacity

500PCS/Month

Product Description

Main feature:

1. English touchable user interface, easy to operate and use.

2. PLC controlling system on machine, which make machine work stably. No need to stop machine to adjust parameters.

3. 10 parameter pre-stored in machne, Easy to change products.

4. Servo motor vacuum membrane, positioned more accurately.

5. Independent temprature controlling system with ± 1 ºC .

Technical paratemer:

| Type | MG-1020 | MG-1200 |

| Bag length | 300-900mm(L) | 300-900mm(L) |

| Bag width | 100-500mm(W) | 100-600mm(W) |

| Max width of roll film | 1020mm | 1200mm |

| Packing speed | 5-6bags/min | 5-6bags/min |

| Measuring range | 5000-20000ml | 5000-25000ml |

| Air consumption | 0.65mpa | 0.65mpa |

| Gas consumption | 0.8m/min | 0.9m/min |

| Power voltage | 220V | 220V |

| Power | 6.2KW | 6.2KW |

| Dimension | (L)1170(W)*820*(H)1285mm | (L)1320(W)*950*(H)1360mm |

| Weight | 1350Kg | 1500Kg |

Application:

It is suitable for automatic packaging of paste of foods, medicine and chemicals, such as pesticide shampoo, and body foam bath lotion, facial cream, ingredient oil, fruit sauce, tomato ketchup and honey etc.

Any question, pls click here to contact us.

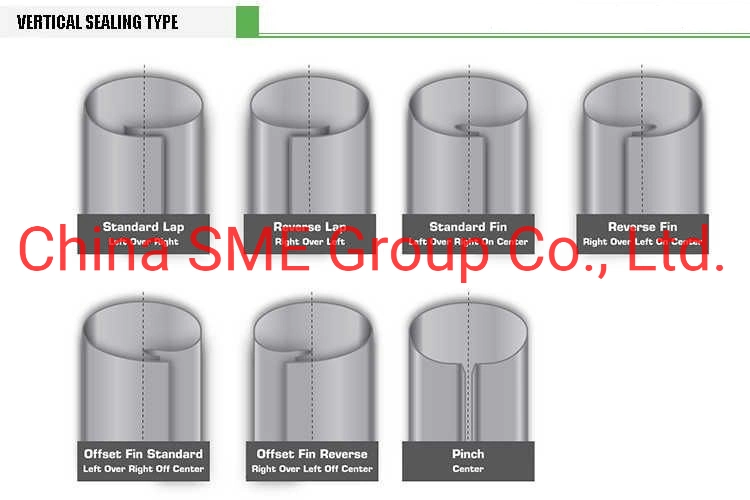

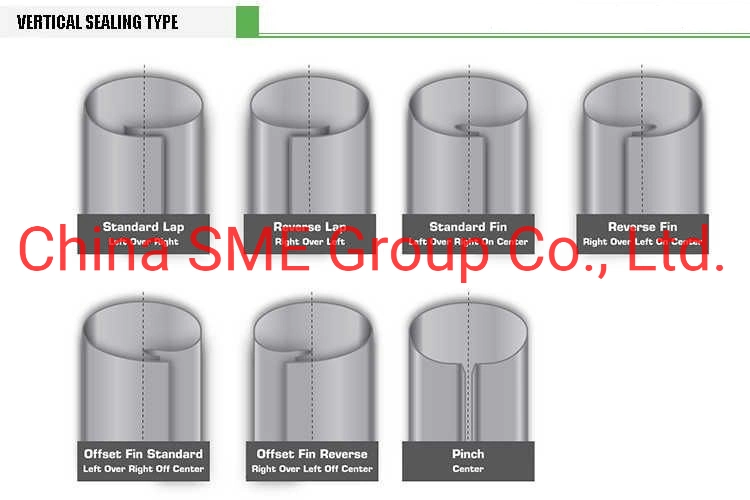

Film Forming Type

How is the liquid packing machine?

>>Main Features

1. Servo auger filler metering system for accurate liquid paste product measuring.

2. Additional leak-proff device avoid powder dusty around.

3. Imported PLC with Servo drive and Servo motor enable machine stable performance.

4. 7 inch touch screen with multiple language are available for easy operation.

5. Memory storage function of ten sets parameter for different product package chaging.

6. Seperate PID temperature control system suits for various kinds of package film sealing.

7. Multi-union roll film structure and sophisticated sealing framework for perfect bag shape forming

| No. | Name | Spe | Origin | Brand | Function |

| 1 | servo motor&driver | 400W | Japan | Panasonic | Traction |

| 2 | Temperature Controller | China | MOTECH | Temperature control | |

| 3 | GPG motor | 60W | China | VTV | Control feed |

| 4 | PLC controller | German | Mitsubishi or Siemens | control program | |

| 5 | HMI | Taiwan | Weinview | Operation panel | |

| 6 | Color photoelectric | USA | Bluegold | Control the bag length | |

| 7 | Thermocouple | Shanghai | Temperature measurement | ||

| 8 | Emergency stop switch | AR22V2R | Shanghai | CHNT | |

| 9 | Proximity switch | ZLJ-C17-5A | Shanghai | CHNT | |

| 10 | solid state relay | 24V,10A | Taiwan | CHNT | Control the brakes |

| 11 | solid state relay | 220V,10A | Taiwan | CHNT | Control the motor |

| 12 | Circuit Breaker | Korean | LG | ||

| 13 | Switching power supply | 24V 6A | Japan | Omron | Regulator |

| 14 | Contactor | Germany | Schneider | ||

| 15 | Heating pipe | Φ10×220, 320 | Shanghai | ||

| 16 | Filter regulator valve | AW40 | Taiwan | AirTAC | |

| 17 | Air-cylinder | Japan | SMC | Horizontal Sealing | |

| 18 | cylinder | B40×15D | Taiwan | AirTAC | Vertical Sealing |

| 19 | electromagnetic valve | Taiwan | AirTAC | Control Vertical Sealing ,Cutting , Culling action | |

| 20 | electromagnetic valve | Taiwan | AirTAC | Control horizontal Sealing |

Our Certification:

1).Famous brand PLC control system,large touch screen,convenient to operate;

(2).Film drawing down system by famous bland servo motor.

(3).Advanced design,high precision and fast speed;

(4).Various alarm system to reduce waste;

(5).Photoelectric tracking system for precise bag length and position of film

(6).Equip with heating and mixing pump,which is more suitable for paste product

(7).Machine case is made of 304 stainless steel,which is more good for food

The filling system is just for your reference. We will offer you best solution according to your product mobility, viscosity, density, volume, dimensions etc.

A. Powder Packing Solution

Servo Screw Auger Filler is specialized for powder filling such as nutrients powder, seasoning powder, flour, medicinal powder etc.

B. Liquid Packing Solution

Piston Pump Filler is specialized for liquid filling such as water, juice, laundry detergent, ketchup etc.

C. Solid Packing Solution

Combination multi-head weigher is specialized for solid filling such as candy, nuts, pasta, dried fruit and vegetable etc.

D. Granule Packing Solution

Volumetric Cup Filler is specialized for granule filling such as chemical, beans, salt, seasonings etc.

E. More Packing Solution

For more solution, welcome to contact us.

Customer &Exhibition

- About US:

SME is a leading manufacturer in the field of front-of-line packaging devices since 2008. In the past 10 years, MOTECH has targeted on the technology development, precise manufacturing, professional marketing, satisfied technical support and OEM solutions. We offer Flow Packing Machine;Vertical Packing Machine;Metal Detector;Weight Checker and Weighter to fit the needs of different industries.

Due to continuous efforts in the field of end-of-line packaging devices, MOTECH Machinery was honored to obtain CE certificate and ISO 9001 certificate showed our emphasis on safety ,quality and has a successful sale in Asia, American, Africa and so on. MOTECH looks forward to establishing a long-term and mutual beneficial partnership with more agents or distributors all over the world. Moreover, We provide the OEM solution based on strict quality control for famous companies in Japan, USA etc.

In the future, MOTECH Machinery will keep to provide customers:

-Quality machines

-Competitive price

-Satisfied service

Our Team: