Basic Info.

Model NO.

THB4-S320L(3 side)

Key Word 1

Juice Sachet Packing Machine

Key Word 2

Milk Packing Machine

Application

Liquid Filling Machine

Transport Package

Wooden Cases

Specification

1100× 800× 1750mm

Trademark

RX

Origin

Henan

Production Capacity

50000

Product Description

Paste Liquid Pouch Honey Tomato Ketchup Small Sachet Packing Machine

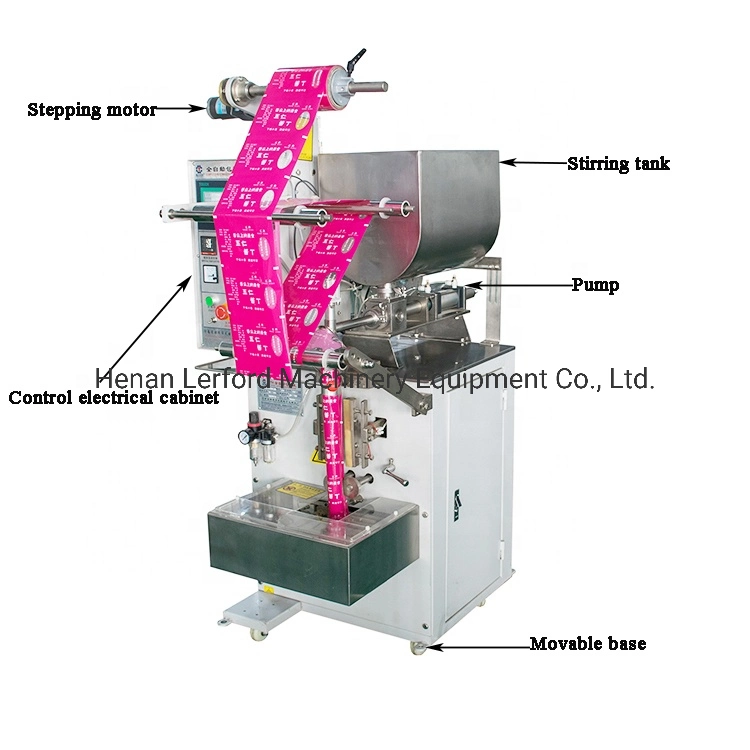

1. Pneumatic injection pump, adjustable injection volume, 304SS.

2. 7 inches touch screen, easy operation and multiple language for choice.

3. Stable software system to ensure smooth operation of the machine. Packing speed and length is settable.

4. With a memory function for storage 10 sets of parameters. Easy to change different packing product and package sizes.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system makes film running more smooth.

7. Double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

Function:

This machine integrates mechanical and electrical functions, two CPU computer control system, large screen LCD, microcomputer control optical tracking correcting system, equipped with high-precision stepper motor, exactly the same position design of each bag, control system of complete synchronization, fixed length, position and speed, automatic fault diagnosis function. Can choose a ribbon typewriter or stamp marking device.

Application:

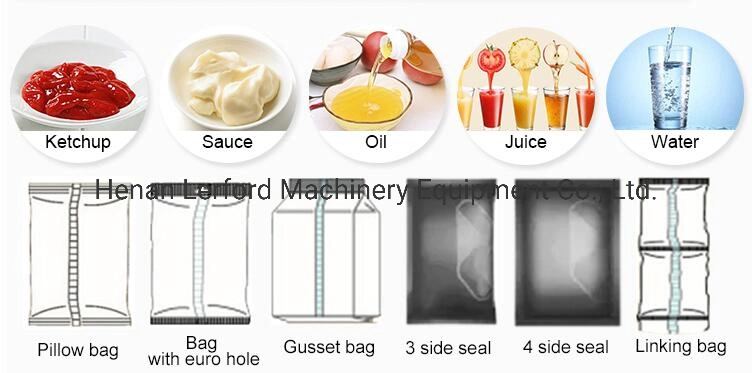

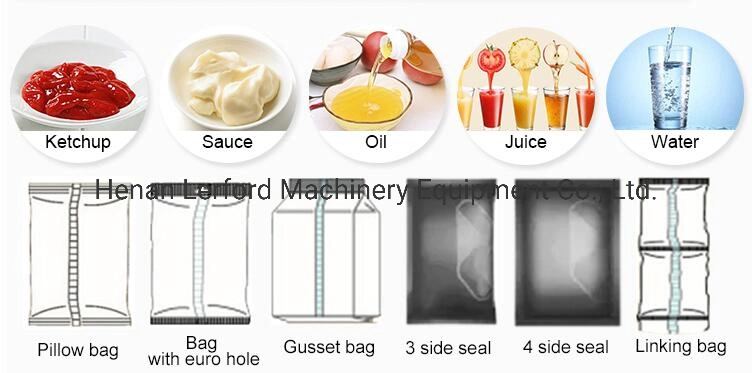

This machine can be used to pack the liquid or paste of food stuff,chemical,and cosmetion,such as shampoo,edible oil,cooking oil,water,honey,juice, drink,liquid milk,tamato paste,suace,ketchup, Liquid Condiment and Cheese Fondue etc.

Technical parameter:

Note: We have several models. Please tell us: Materials, Packing weight, bag width /length, we will customize a suitable solution for you according to your requirment.

Juice, Honey, Ketchup, Peanut butter, Garlic sauce, Milk, condensed milk, Shampoo, gel, emulsion, lotion, Liquid detergent, liquid soap…

Standard setting:

- Closed sealer housing

- Intuitive operator guidance on the button/touch panel

- Integration of all identification systems

- Printed mark identification & measurement of bag lengths

- Use of different heat sealing and welding instruments

- Minimal time required when changing rolls

- Stop when film roll end. Detect the fault automatically.

- Seal tight, no leaking.

Available option spare parts:

- Stainless steel and Paint version

- Display panel: Touch screen and Button screen

- Date & batch printer

- Date embossing system

- Exhaust sponge system, less air inside the packet

- Easy tearing notch

- Round and euro-hole punch, carrying handle punch

- Insulation and stirring system

- Numerical control cutter, 1-99 packet

- Flat bottom package with center seal

- Frequency control system, less noise

- Power supply: - 110V, 120V, 220V, 240V. - 50Hz, 60Hz.

- Bottom holding set

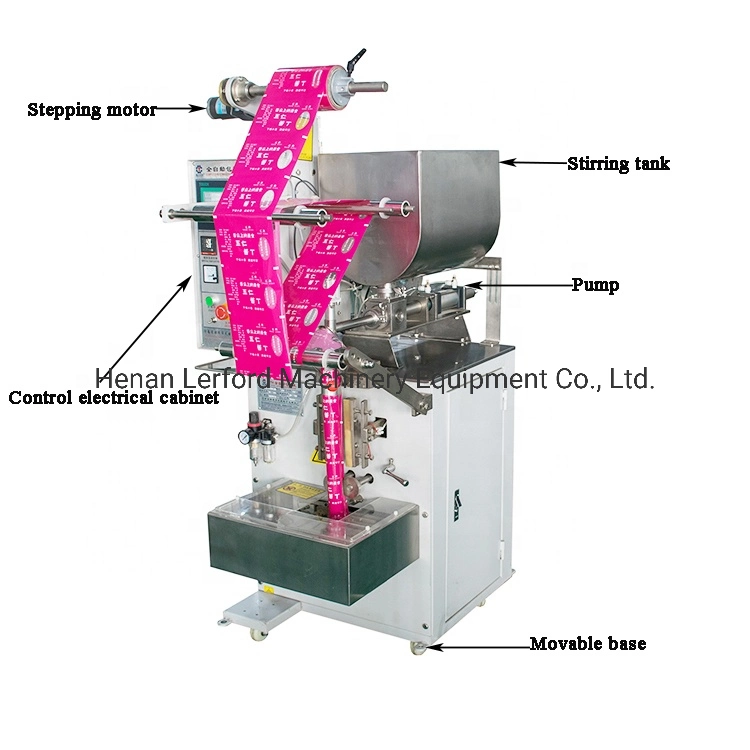

1. Pneumatic injection pump, adjustable injection volume, 304SS.

2. 7 inches touch screen, easy operation and multiple language for choice.

3. Stable software system to ensure smooth operation of the machine. Packing speed and length is settable.

4. With a memory function for storage 10 sets of parameters. Easy to change different packing product and package sizes.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system makes film running more smooth.

7. Double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

Function:

This machine integrates mechanical and electrical functions, two CPU computer control system, large screen LCD, microcomputer control optical tracking correcting system, equipped with high-precision stepper motor, exactly the same position design of each bag, control system of complete synchronization, fixed length, position and speed, automatic fault diagnosis function. Can choose a ribbon typewriter or stamp marking device.

Application:

This machine can be used to pack the liquid or paste of food stuff,chemical,and cosmetion,such as shampoo,edible oil,cooking oil,water,honey,juice, drink,liquid milk,tamato paste,suace,ketchup, Liquid Condiment and Cheese Fondue etc.

Technical parameter:

| Model | THB4 -S320L(Pillow) | THB4-S320L(3 side) | THB4 -S320L(4 side) |

| Film Width | Max. 300 mm | Max. 320 mm | Max. 320 mm |

| Bag Length | 60-200 mm | 60-200 mm | 60-200 mm |

| Bag Width | 40-140 mm | 40-160 mm | 40-160 mm |

| Packaging Speed | 15-40 bags/minute | 15-40 bags/minute | 15-40 bags/minute |

| Range of Metering | 10-500 ml | 10-400 ml | 10-400 ml |

| Film Thickness | 0.04-0.12 mm | 0.04-0.12 mm | 0.04-0.12 mm |

| Power | 220V 50Hz 2KW | 220V 50Hz 2KW | 220V 50Hz 2KW |

| Dimension | 1100×800×1750mm | 1100×800×1750mm | 1100×800×1750mm |

| Net Weight | About 300 KG | About 300 KG | About 300 KG |

Note: We have several models. Please tell us: Materials, Packing weight, bag width /length, we will customize a suitable solution for you according to your requirment.