Basic Info.

Model NO.

YB-W35

After-sales Service

12 Month

HS

8441309000

Transport Package

Wooden Box by Sea

Trademark

Yongbo

Origin

Ruian

Production Capacity

1000sets/Year

Product Description

YB-W35 Paper Bowl machine

------Quotation: The ex factory price of yb-w35 paper bowl machine including tax and wooden box packaging is 129000 RMB.

------Quotation: The ex factory price of yb-w35 paper bowl machine including tax and wooden box packaging is 129000 RMB.

------Packing type: Wooden base plate, damp proof plastic lining, fully-closed plate-box external

------Delivery time: 40 days after receive the payment of deposit

------Payment: Deposit 30% by T/T in advance, delivery against payment of 70% balance after qualified acceptance

------Leave factory testing: before leaving factory, equipment should be tested by both parties. Test material offered by buyer

------Installation: we will send 1 technicians for machine's installation and debugging according to customer's requirement; the technician's board and lodging and the round-trip airplane ticket expense undertakes by the buyer,additional service charge USD100.For each technician/one day, estimate 5-7 working days

------Guarantee period: Guarantee period is 12 months after getting the machine

------The supplier shall provide the service:(after pay the machine)

------the supplier to send adjustment of installation and commissioning

------the supplier direct buyer's technical personnel operating the machine

------The buyer shall provide the facilities and preparations:(Delivery machine to finish)

------foundation and adapter power supply water and compressed air pipe and related projects

Reliability:

YB-W35 intelligent medium-speed paper bowl forming machine has the advantages of high performance, high efficiency and high quality;

The integral steel body and the auto oil lubrication system ensure long-term normal and stable operation of the machine

Energy efficient:

The advanced high-precision open cam drive and gear drive make it more accurate and stable; Servo tracking bottom paper feeding locks the size of the bottom paper , which effectively saves raw materials;

Humanizing:

The man-machine interface PLC system controls the long-term stable operation of the whole machine.

Technical parameter:

Specifications details of machine :

1.Multiple times Paper feeding: Paper feeding three times, multiple adjustments to avoid unevenness on both sides of the paper cup fan.

2.Sensors detection: the machine is controlled by encoder and sensors which ensure that a paper fan matches with a cup bottom to avoid waste at the same time. Fault alarm,automatic shutdown.

2.Sensors detection: the machine is controlled by encoder and sensors which ensure that a paper fan matches with a cup bottom to avoid waste at the same time. Fault alarm,automatic shutdown.

3.PLC control system: The machine uses PLC control to improve intelligence and make the stroke more precise and accurate , all the working parameters can be setup on the control panel. Easy to operate and adjust the parameter.

3.PLC control system: The machine uses PLC control to improve intelligence and make the stroke more precise and accurate , all the working parameters can be setup on the control panel. Easy to operate and adjust the parameter.

4.Ultrasonic cooling fan: multiple fans operate at the same time to increase heat dissipation capability and speed up cooling, so that the machine maintains an appropriate temperature during the running.

4.Ultrasonic cooling fan: multiple fans operate at the same time to increase heat dissipation capability and speed up cooling, so that the machine maintains an appropriate temperature during the running.

5.Automatic oil lubrication system: The machine automatically lubricates each location of key moving parts by copper pipes, saving labor and making the machine life longer service life.

5.Automatic oil lubrication system: The machine automatically lubricates each location of key moving parts by copper pipes, saving labor and making the machine life longer service life.

6.Bottom waster paper removal: Using the conveyor belt to transfer the waste paper. Avoid waste paper falling into the inside of machine when the machine is on running , which is difficult to clean and affects the work of the machine.

6.Bottom waster paper removal: Using the conveyor belt to transfer the waste paper. Avoid waste paper falling into the inside of machine when the machine is on running , which is difficult to clean and affects the work of the machine.

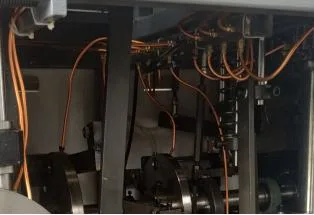

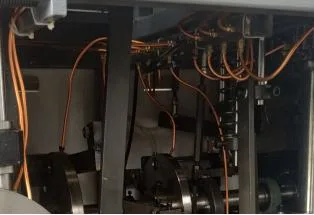

7.Grooved wheel and full gears drive system: The inside of the machine is connected by the grooved wheel and gears , which make the connections of various parts closer, and the connection parts of machine are not easy to get loose during the running of the machine. It also makes the cup forming process more accurate ,stable, and less troubles .

7.Grooved wheel and full gears drive system: The inside of the machine is connected by the grooved wheel and gears , which make the connections of various parts closer, and the connection parts of machine are not easy to get loose during the running of the machine. It also makes the cup forming process more accurate ,stable, and less troubles .

8.bottom paper directly punching and feeding : in the normal design, the complicated suction bottom and paper feeding process makes the bottom turning over easily . The machine is changed to use direct punch bottom feeding method in one step to avoid bottom turning over .

8.bottom paper directly punching and feeding : in the normal design, the complicated suction bottom and paper feeding process makes the bottom turning over easily . The machine is changed to use direct punch bottom feeding method in one step to avoid bottom turning over .

Spare parts list:

Spare parts list:

Company introduction

More information contact me anytime !

------Quotation: The ex factory price of yb-w35 paper bowl machine including tax and wooden box packaging is 129000 RMB.

------Quotation: The ex factory price of yb-w35 paper bowl machine including tax and wooden box packaging is 129000 RMB. ------Packing type: Wooden base plate, damp proof plastic lining, fully-closed plate-box external

------Delivery time: 40 days after receive the payment of deposit

------Payment: Deposit 30% by T/T in advance, delivery against payment of 70% balance after qualified acceptance

------Leave factory testing: before leaving factory, equipment should be tested by both parties. Test material offered by buyer

------Installation: we will send 1 technicians for machine's installation and debugging according to customer's requirement; the technician's board and lodging and the round-trip airplane ticket expense undertakes by the buyer,additional service charge USD100.For each technician/one day, estimate 5-7 working days

------Guarantee period: Guarantee period is 12 months after getting the machine

------The supplier shall provide the service:(after pay the machine)

------the supplier to send adjustment of installation and commissioning

------the supplier direct buyer's technical personnel operating the machine

------The buyer shall provide the facilities and preparations:(Delivery machine to finish)

------foundation and adapter power supply water and compressed air pipe and related projects

Reliability:

YB-W35 intelligent medium-speed paper bowl forming machine has the advantages of high performance, high efficiency and high quality;

The integral steel body and the auto oil lubrication system ensure long-term normal and stable operation of the machine

Energy efficient:

The advanced high-precision open cam drive and gear drive make it more accurate and stable; Servo tracking bottom paper feeding locks the size of the bottom paper , which effectively saves raw materials;

Humanizing:

The man-machine interface PLC system controls the long-term stable operation of the whole machine.

Technical parameter:

| Model | YB-W35 automatic paper bowl forming machine |

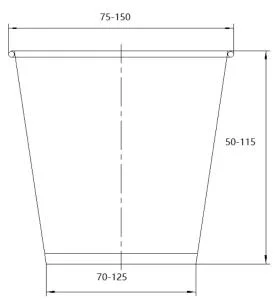

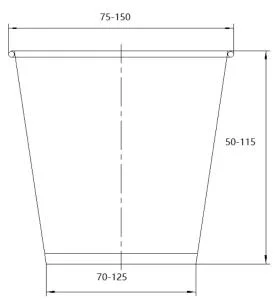

| Cup size | 20-50oz(mould can be changed as the requirements of clients) |

| Raw materials | Single /Double PE coated paper |

| Paper weight | 140-350gsm |

| speed | 60-75pcs/min |

| Power source | 380V 50Hz |

| Total Power | 4.8KW |

| Weight | 2400KG |

| dimension | 2450 x1300 x1750mm; |

| L*W*H | |

| Air pressure requirements | 0.6Mpa, output :0.6 m3/minute |

| Machine should work with the air compressor | |

1.Multiple times Paper feeding: Paper feeding three times, multiple adjustments to avoid unevenness on both sides of the paper cup fan.

2.Sensors detection: the machine is controlled by encoder and sensors which ensure that a paper fan matches with a cup bottom to avoid waste at the same time. Fault alarm,automatic shutdown.

2.Sensors detection: the machine is controlled by encoder and sensors which ensure that a paper fan matches with a cup bottom to avoid waste at the same time. Fault alarm,automatic shutdown.

3.PLC control system: The machine uses PLC control to improve intelligence and make the stroke more precise and accurate , all the working parameters can be setup on the control panel. Easy to operate and adjust the parameter.

3.PLC control system: The machine uses PLC control to improve intelligence and make the stroke more precise and accurate , all the working parameters can be setup on the control panel. Easy to operate and adjust the parameter.  4.Ultrasonic cooling fan: multiple fans operate at the same time to increase heat dissipation capability and speed up cooling, so that the machine maintains an appropriate temperature during the running.

4.Ultrasonic cooling fan: multiple fans operate at the same time to increase heat dissipation capability and speed up cooling, so that the machine maintains an appropriate temperature during the running.  5.Automatic oil lubrication system: The machine automatically lubricates each location of key moving parts by copper pipes, saving labor and making the machine life longer service life.

5.Automatic oil lubrication system: The machine automatically lubricates each location of key moving parts by copper pipes, saving labor and making the machine life longer service life.  6.Bottom waster paper removal: Using the conveyor belt to transfer the waste paper. Avoid waste paper falling into the inside of machine when the machine is on running , which is difficult to clean and affects the work of the machine.

6.Bottom waster paper removal: Using the conveyor belt to transfer the waste paper. Avoid waste paper falling into the inside of machine when the machine is on running , which is difficult to clean and affects the work of the machine.  7.Grooved wheel and full gears drive system: The inside of the machine is connected by the grooved wheel and gears , which make the connections of various parts closer, and the connection parts of machine are not easy to get loose during the running of the machine. It also makes the cup forming process more accurate ,stable, and less troubles .

7.Grooved wheel and full gears drive system: The inside of the machine is connected by the grooved wheel and gears , which make the connections of various parts closer, and the connection parts of machine are not easy to get loose during the running of the machine. It also makes the cup forming process more accurate ,stable, and less troubles .  8.bottom paper directly punching and feeding : in the normal design, the complicated suction bottom and paper feeding process makes the bottom turning over easily . The machine is changed to use direct punch bottom feeding method in one step to avoid bottom turning over .

8.bottom paper directly punching and feeding : in the normal design, the complicated suction bottom and paper feeding process makes the bottom turning over easily . The machine is changed to use direct punch bottom feeding method in one step to avoid bottom turning over .  Spare parts list:

Spare parts list: | Name | Quantity |

| Electrical heating rod | 1pcs |

| Adjustable spanner 10inch | 1pcs |

| Small Springs | 3pcs |

| Preheat heating collar | each 1pc |

| Heater ring | 2 pcs |

| Bearing 5204 + Knurling wheel | 1set |

| inner hexagonal spanner | 1set |

| open-end wrench 8-10 12-14 17-19 22-24 | 1set |

| foot-screw M18 | 6pcs |

| Oil Gun | 1pcs |

| Neon-electroscope | 1pcs |

| Screwdriver(+) | 1pcs |

| Hammer | 1pcs |

| Operation Handle | 1pcs |

| Electrical tape | 1pcs |

| offset ring spanner 12-14 17-19 | each 1pcs |

| Nipper Pliers | 1pcs |

| Suckers | 3pcs |

| inner hexagon screws 6,8,10,12 each 2pcs | 8pcs |

| 12 Nut flat washer 12 nut 5pcs | 10pcs |

| Operation manual | 1pcs |

| Inverter manual | 1pcs |

Company introduction

More information contact me anytime !