Basic Info.

Forming Function

Seal

Driven Type

Electric

Material Type

Solid

Packaging

Bag

Packaging Material

Plastic

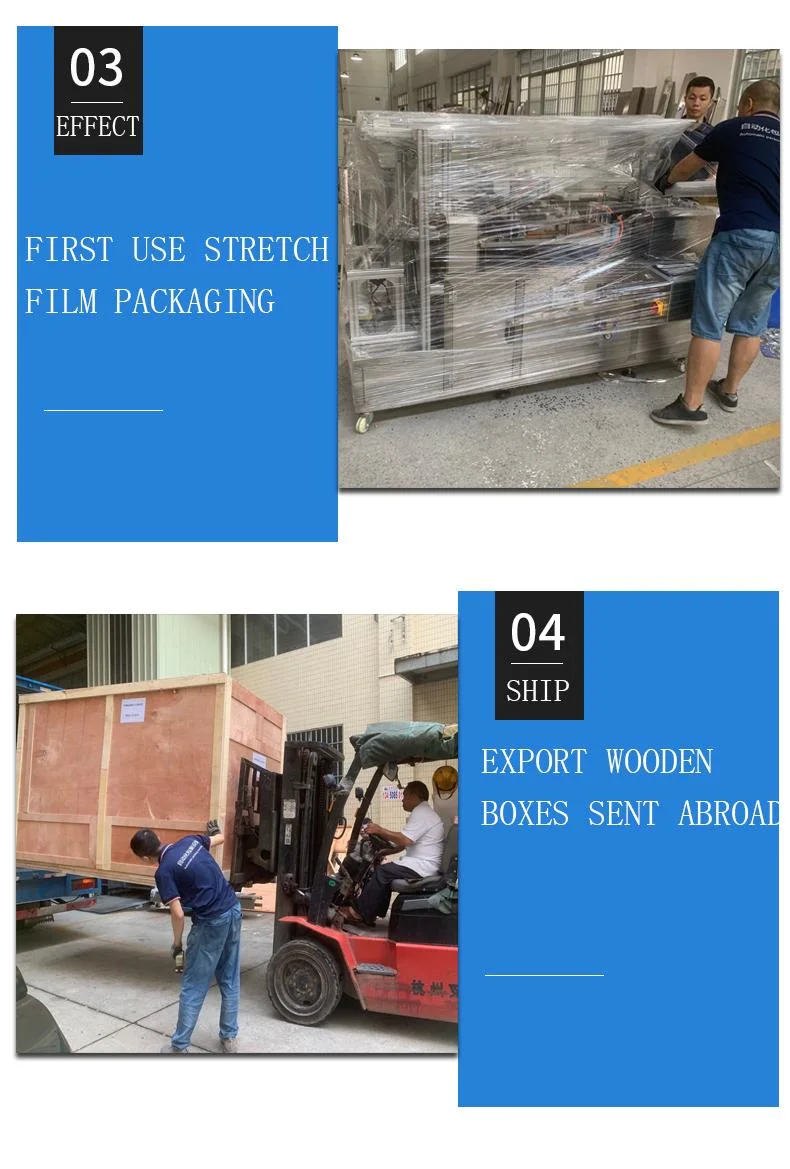

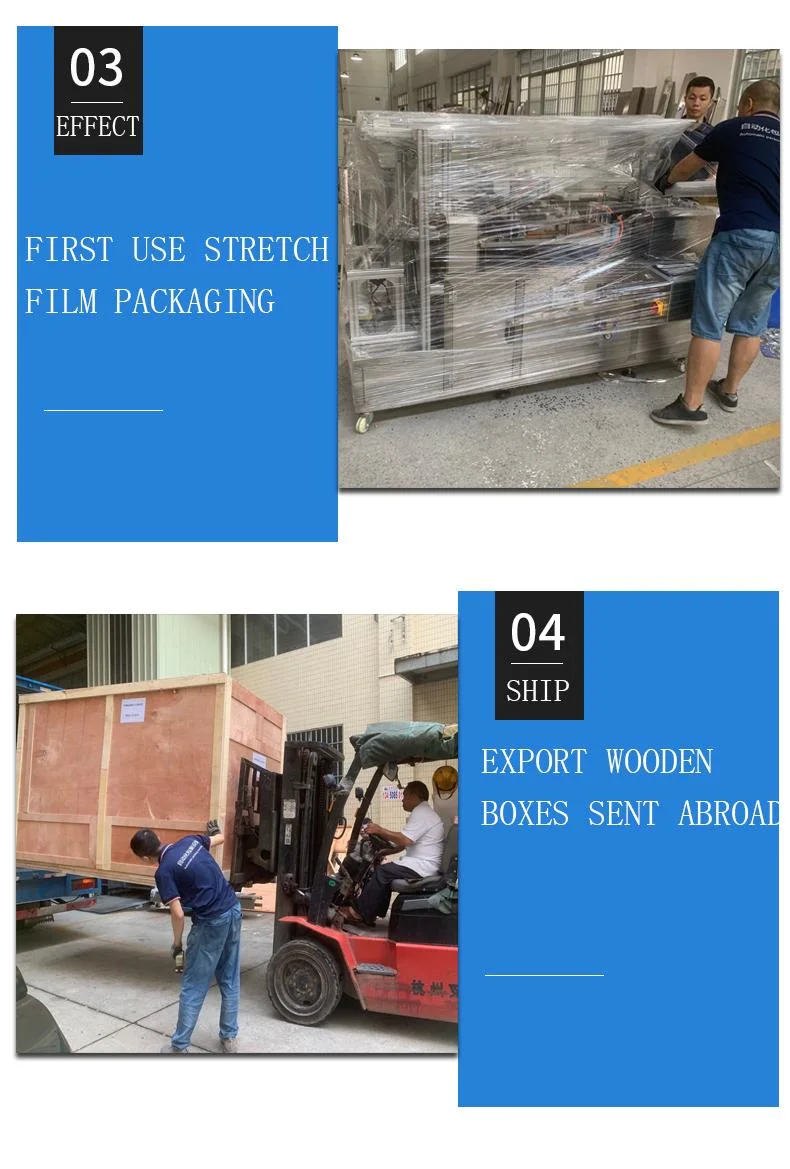

Transport Package

Export Wooden Box

Specification

4200*950*1600 MM

Trademark

SAYOK

Origin

China

HS Code

8422303090

Production Capacity

100peice/Month

Product Description

Feature:

1. Straight parting feeding packing machine: convey platform & transitional convey part & steering machine & automatic feeding part & packing machine.

2. Available feeding directions:the vertical and horizontal feeding system, vertical layout of workshop.

3. Application: cake, bread, biscuit, sweetheart pastry, green bean pastry, chocolate pastry, and so on.

4. Machine advantage :Automatic sorting system advantage: apply to orderly products and disorderly products .Simple structure, convenient operation, and easy to set up. Wide belt make the assembly and dis-assemblyconvenient, fast.

5. Advantage of automatic feeding: Accurateand quick positioning. Convenient to set the machine when packing products of different specifications, simple adjustment .The belt can accelerate without tool dis-assembly.Simple structure, easy cleaning

.

The finishing line and automatic feeding is controlled by the same control system, speed on the linkage mechanism, i.e., when the back end is less material, the front end will accelerate feeding. When the back end stop, the front end will stop, thus reduce the packing machine downtime frequency, ensure the high sealing quality .Shunting type material distribution system adopts centralized control technology, to adjust the speed according to the material, automatically adjust the allocation of the number. The system

consists of a material guiding unit, shunting unit, receiving unit, feeding unit, packing unit, storage unit, control unit.

Through the guide unit, the system realize the flexible shunt on materials; shunt unit through the traffic moving, assigning products to the pre-set receiving unit; the storage unit through the material distributing system instruction, will store the split products in the cache, when the packing line can meet the packaging, through the circulatory system, material distribution again into the packaging line, thus ensure the entire line meet the needs of uninterrupted production.

2. Available feeding directions:the vertical and horizontal feeding system, vertical layout of workshop.

3. Application: cake, bread, biscuit, sweetheart pastry, green bean pastry, chocolate pastry, and so on.

4. Machine advantage :Automatic sorting system advantage: apply to orderly products and disorderly products .Simple structure, convenient operation, and easy to set up. Wide belt make the assembly and dis-assemblyconvenient, fast.

5. Advantage of automatic feeding: Accurateand quick positioning. Convenient to set the machine when packing products of different specifications, simple adjustment .The belt can accelerate without tool dis-assembly.Simple structure, easy cleaning

.

The finishing line and automatic feeding is controlled by the same control system, speed on the linkage mechanism, i.e., when the back end is less material, the front end will accelerate feeding. When the back end stop, the front end will stop, thus reduce the packing machine downtime frequency, ensure the high sealing quality .Shunting type material distribution system adopts centralized control technology, to adjust the speed according to the material, automatically adjust the allocation of the number. The system

consists of a material guiding unit, shunting unit, receiving unit, feeding unit, packing unit, storage unit, control unit.

Through the guide unit, the system realize the flexible shunt on materials; shunt unit through the traffic moving, assigning products to the pre-set receiving unit; the storage unit through the material distributing system instruction, will store the split products in the cache, when the packing line can meet the packaging, through the circulatory system, material distribution again into the packaging line, thus ensure the entire line meet the needs of uninterrupted production.

| Model | SN-250X | SN-350X | SN-450X | SN-600X | SN-700X |

| Film width | 250mm | 350mm | 450mm | 600mm | 700mm |

| Bag length | 65-190mm or 100-300mm | 65-190mm or 100-400 mm | 100-450mm | 120-500mm | 120-500mm |

| Bag width | 30-110mm | 50-160mm | 50-180mm | 100-280mm | 100-330mm |

| Product's height | max.45mm | Max.65mm | max.80mm | max.80mm | max.80mm |

| Packing speed | 40-230bags/min | 30-300bags/min | 30-150bags/min | 30-150bags/min | 30-150bags/min |

| Power | 220V 50/60HZ 2.4KW | 220V 50/60HZ 2.8KW | 220V 50/60HZ 2.8KW | 220V 50/60HZ 2.8KW | 220V 50/60HZ 2.8KW |

| Machine size | 3920x670x1320 | 4020x720x1320 | 4020x820x1450 | 4020x920x1460 | 4020x980x1480 |

| Machine weight | 500kg | 550kg | 580kg | 610kg | 680kg |

Foshan Sayok Packaging Machinery Co.,Ltd., located in Foshan, Guangdong, is dedicated to developing and producing various packaging machinery. With advanced R & D concept, professional technology, mature processing system, rigorous QC management system and considerate after-sales service, we have won a good reputation in the industry. With rich industry knowledge and service experience, we can offer our clients one-stop packaging solutions. We welcome you to visit our factory, and talk about business face to face with us. We firmly believe that our rise in the industry can't be achieved without your support. We aim to produce more advanced products and co-advance with our clients.

Since we set up the company, we have developed dozens of packaging machines and corollary equipments in several series. From double frequency conversion packaging machine series to advanced three servo packaging machine, and then full-automatic packaging production line. After continuous improving and perfecting, our production techniques have reached industry standard, and thus helped us to win many distributors.