Basic Info.

Model NO.

DCWB-350X

Customized

Customized

Product Name

Dcwb-350X Pillow Packing Machine

Function

Pillow Bakery Cookie Food Flow Packing Machine

Material

Stainless Steel

Transport Package

Wooden

Trademark

Xingle

Origin

China Guangdong

Production Capacity

100 Sets/Month

Product Description

Product Description

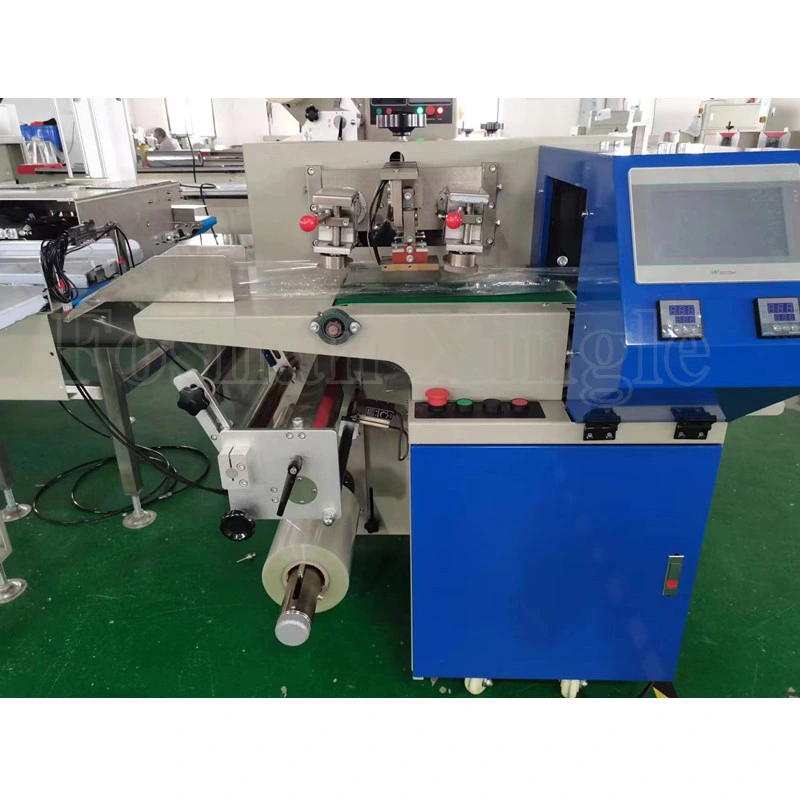

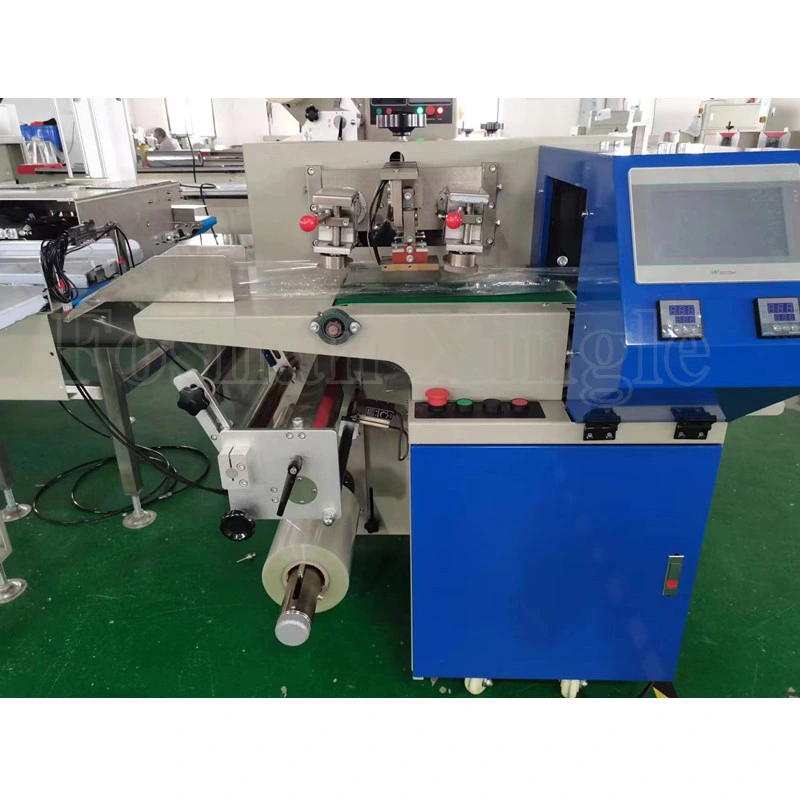

DCWB-350X Pillow Packing Machine

Application

DCWB-350X Pillow Packing Machine

Product description:

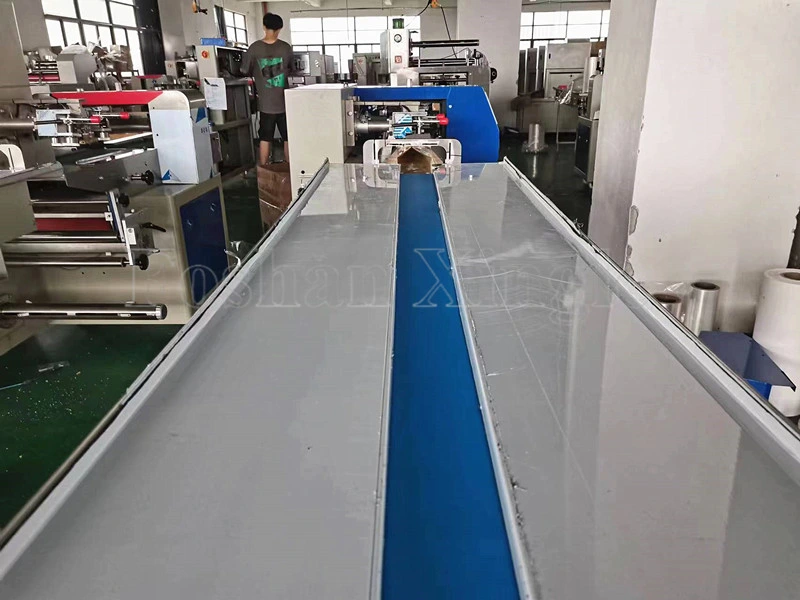

1. The machine consists of a feeding tail frame, a film feeding mechanism, a main frame, an end sealing mechanism, a middle sealing mechanism, a finished product conveying mechanism, a screen temperature control operating system and button operations.

2. Three-servo configuration, the frame is painted on carbon steel, and the parts in contact with the product are made of 304 stainless steel.

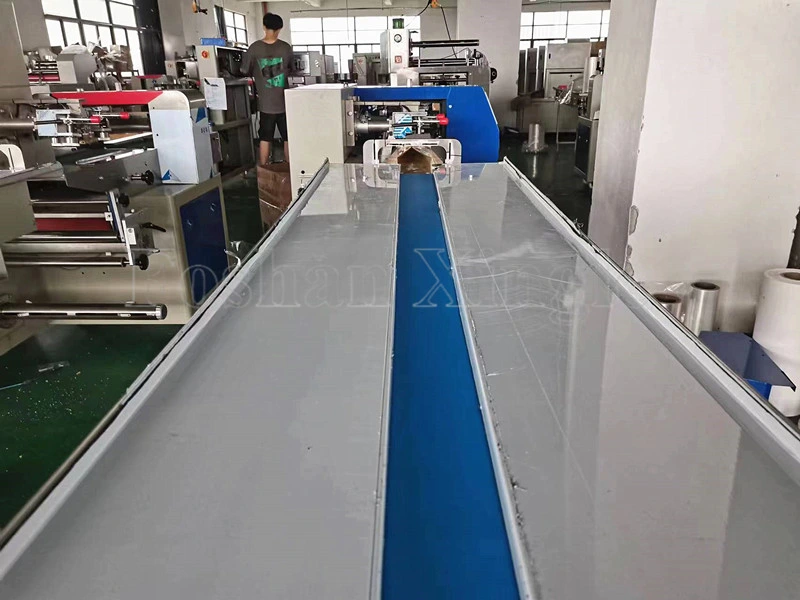

Work process: The product is placed on the feeding tailstock, or connected to the production line, and is automatically pushed to the bag forming machine. After middle sealing and end sealing, the bagging is completed, heat-sealed into bags, and transported to the finished product through the belt output.

Performance features:

1. The machine consists of a feeding tail frame, a film feeding mechanism, a main frame, an end sealing mechanism, a middle sealing mechanism, a finished product conveying mechanism, a screen temperature control operating system and button operations.

2. Three-servo configuration, the frame is painted on carbon steel, and the parts in contact with the product are made of 304 stainless steel.

Work process: The product is placed on the feeding tailstock, or connected to the production line, and is automatically pushed to the bag forming machine. After middle sealing and end sealing, the bagging is completed, heat-sealed into bags, and transported to the finished product through the belt output.

Performance features:

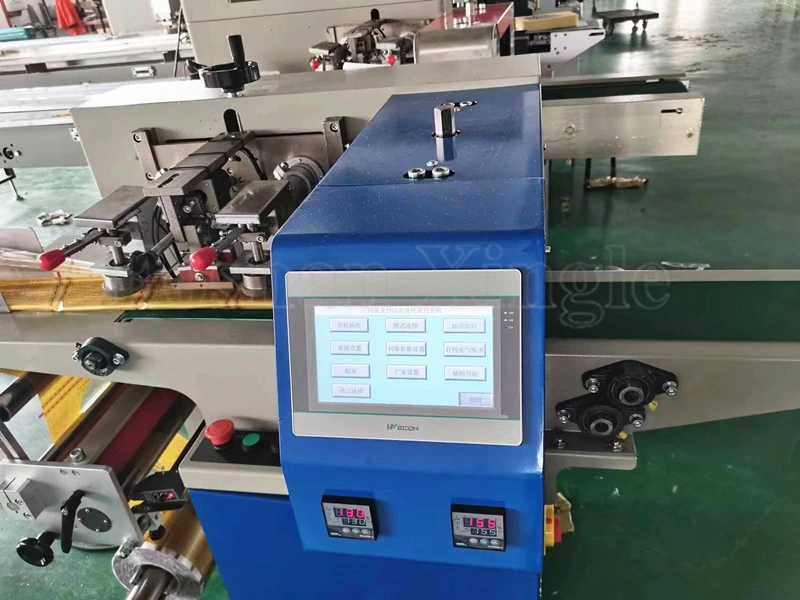

1. Three servo controls, the bag length can be set and cut without any need to adjust the idling, and it can be completed in one step, saving time and film.

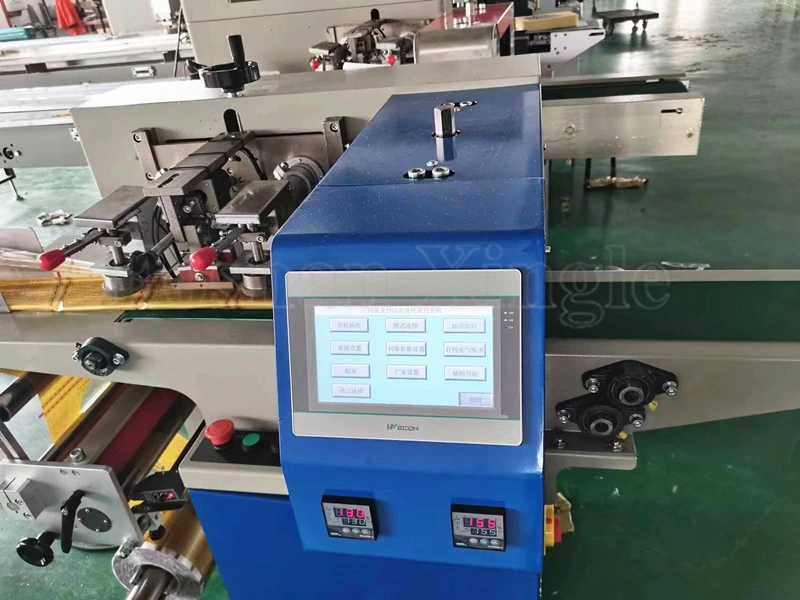

2. Human-machine interface, touch screen, convenient and quick parameter setting.

3. Fault self-diagnosis function, fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input of sealing and cutting position, making the sealing and cutting position more accurate.

5. Independent PID control of temperature, precise temperature control, better suitable for various packaging materials.

6. Positioning stop function, no knife sticking, no waste of film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. All controls are realized by software, which facilitates function adjustment and technology upgrade and never lags behind.

9. Anti-cutting function, non-stop, can prevent cutting, improve machine operating efficiency and reduce equipment loss. (optional)

10. Anti-empty bag function, material shortage detection, film cutting knife stop, push material automatically replenished. No empty packages, no wasted packaging. (optional)

11. End sealing and gusseting device makes the bag shape more beautiful and improves product quality. (optional)

3. Fault self-diagnosis function, fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input of sealing and cutting position, making the sealing and cutting position more accurate.

5. Independent PID control of temperature, precise temperature control, better suitable for various packaging materials.

6. Positioning stop function, no knife sticking, no waste of film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. All controls are realized by software, which facilitates function adjustment and technology upgrade and never lags behind.

9. Anti-cutting function, non-stop, can prevent cutting, improve machine operating efficiency and reduce equipment loss. (optional)

10. Anti-empty bag function, material shortage detection, film cutting knife stop, push material automatically replenished. No empty packages, no wasted packaging. (optional)

11. End sealing and gusseting device makes the bag shape more beautiful and improves product quality. (optional)

Main Parameter:

| Product Name | DCWB-350X Pillow Packing Machine |

| Model | DCWB-350X |

| Type | Rotary |

| Film width | Max:350mm |

| Packing length | 130-300mm. |

| Product width | 60~150mm |

| Product height | Max:55mm |

| Film roll diameter | Max: 320mm |

| packaging speed | 40~250 packs/min |

| Power Specifications | 220V,50/60Hz,3.2KW |

| Machine weight | 400Kg |

Application

COMPANY PROFILE

Xingle Machinery

Foshan Xingle Machinery Equipment Co., Ltd. is a professional manufacturer and supplier of machinery and enjoys a good reputation in local and global markets. We are specialized imachines including pulverizes, mixer, Granulator, coating machine, counting machine, blister packaging machine, cartoning machine, labeling machine,ampoule filling and sealing machine, oral liquid filling production line, ampoule printing machine, suppository machine, we can undertake concept design, process design turnkey project and so on.\nHigh-quality machinery, competitive prices and sincere customer service are highly appreciated by customers. Our machines have been exported to many countries in the world, North America, Europe, Australia, South America, Southeast Asia and Africa. In order to provide the best quality, the products we manufacture comply with GMP, cGMP and other international standards.