Basic Info.

Model NO.

HY-70/95

Forming Area

700X 950 mm

Forming Depth

125mm

Suitable Material

OPS/PVC/HIPS/Pet/PS

Sheet Thickness Range

0.15-1mm

Knife Length

APET:12000mm / OPS:18000 mm

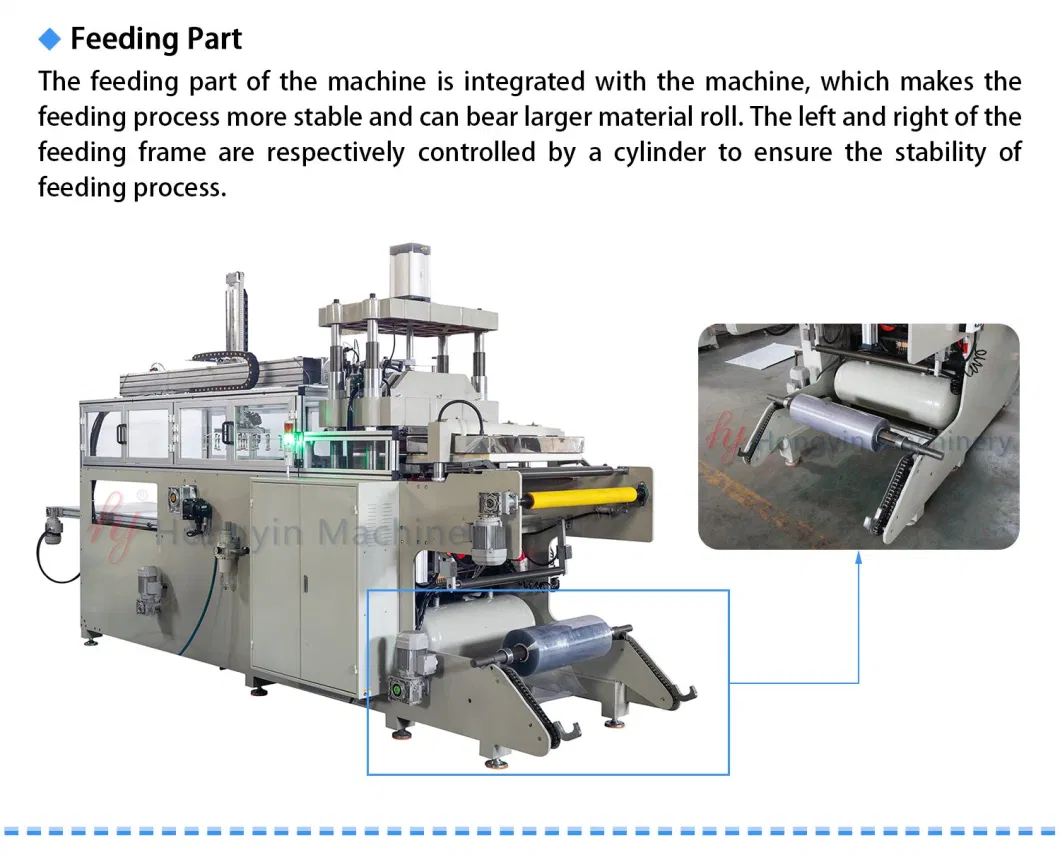

Max Sheet Roll Width

1000mm

Voltage

AC380V±15V,50Hz

Working Speed

600-1400 Cycles/Hr

Air Pressure

0.7MPa

Air Consumption

2000 Litres/Min

Water Consumption

15 Liters/Min(15-20ºC)

Motor Power

13kw

Heating Power

38kw

Weight

6800kg

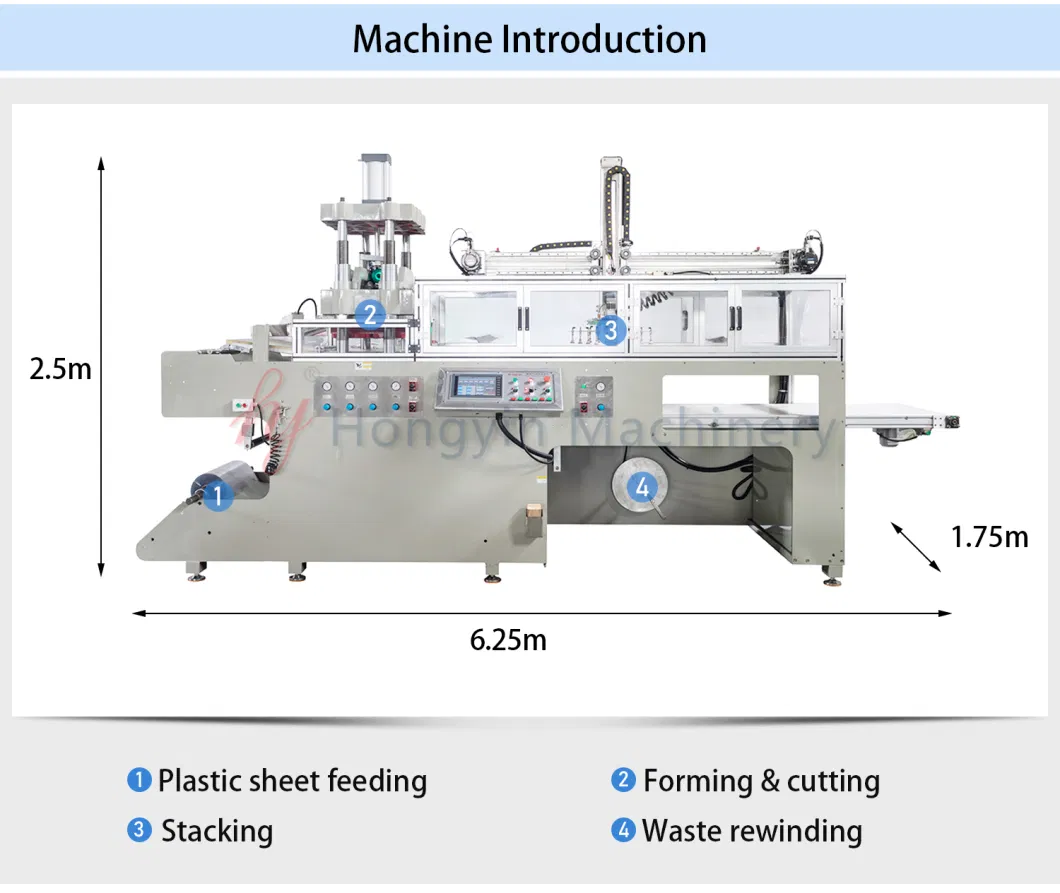

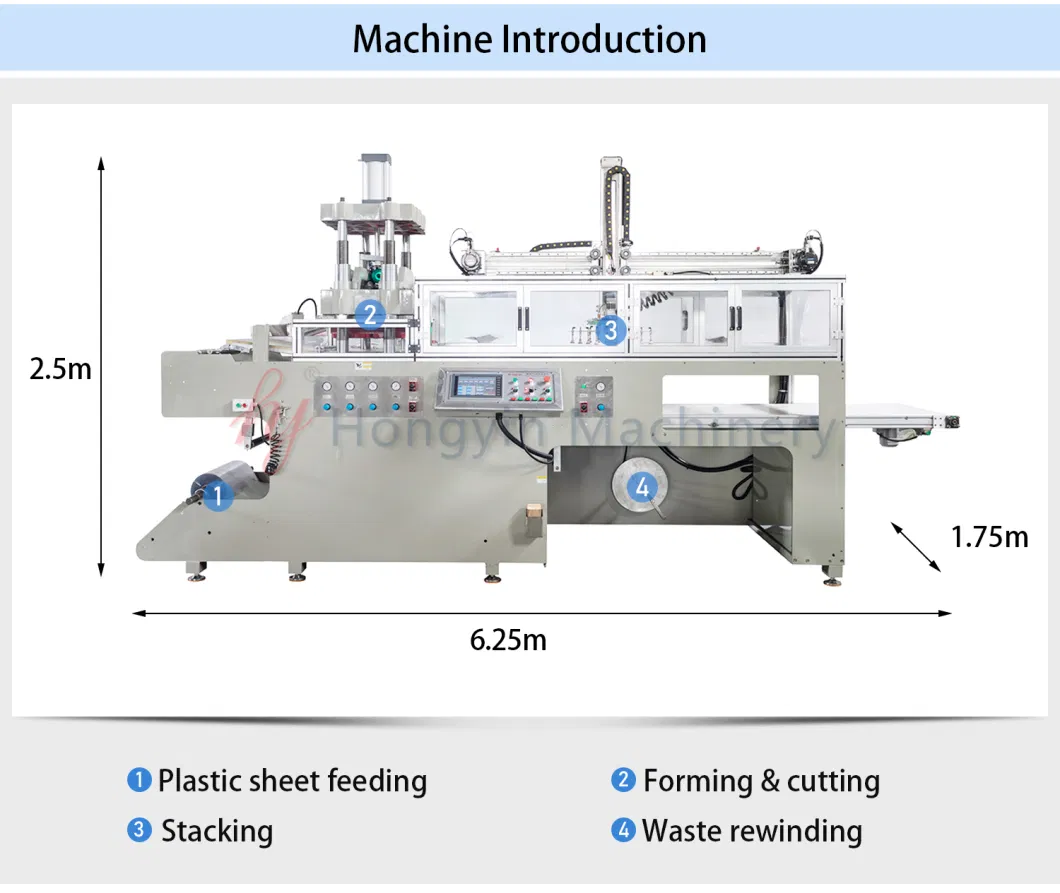

Dimensions

6590X1760X2720mm

Transport Package

Wooden Packaging

Specification

6800kg

Trademark

Hongyin

Origin

China

Production Capacity

5 Sets Per Month

Product Description

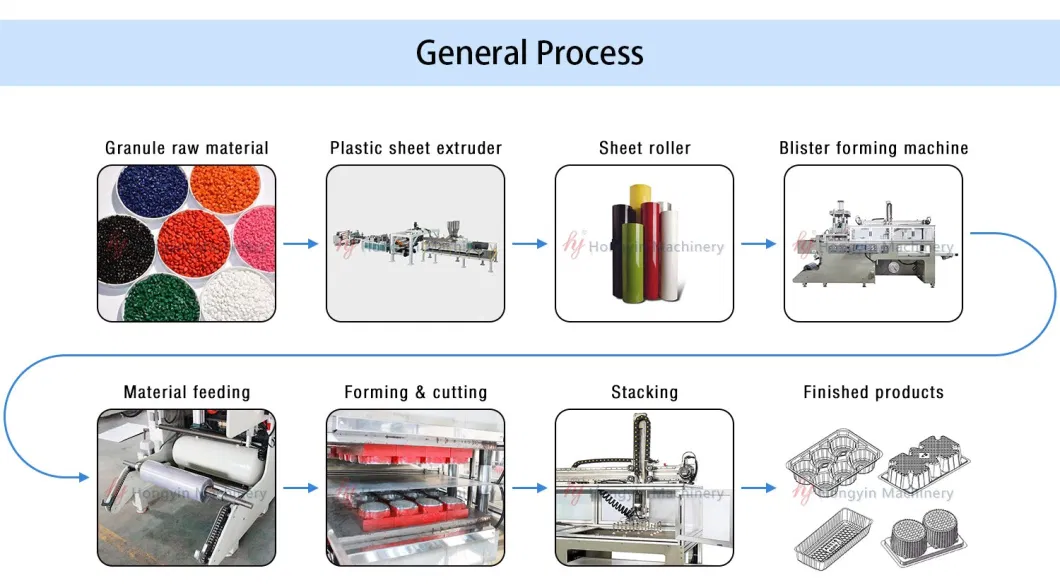

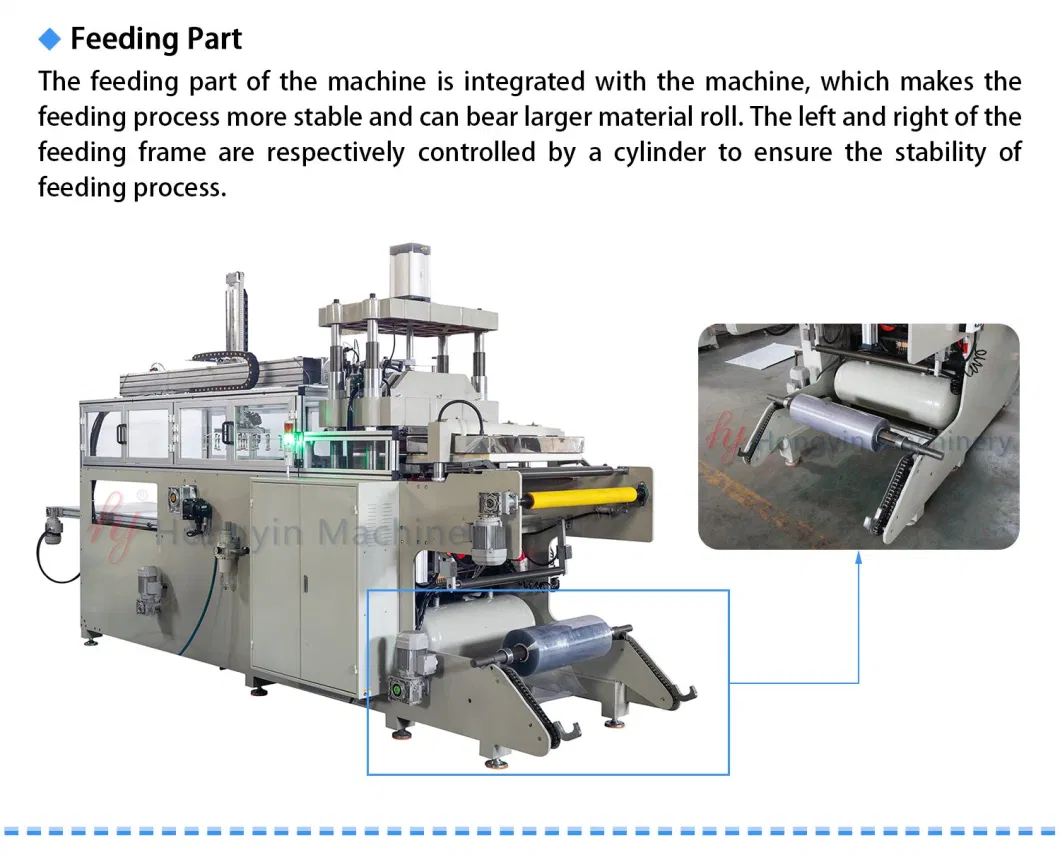

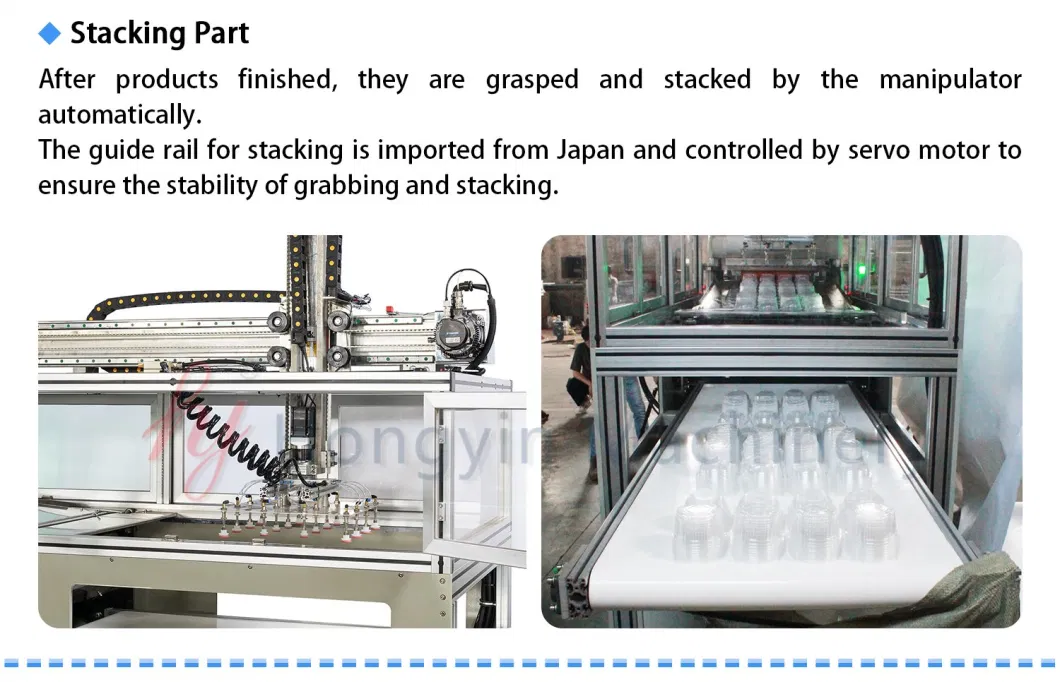

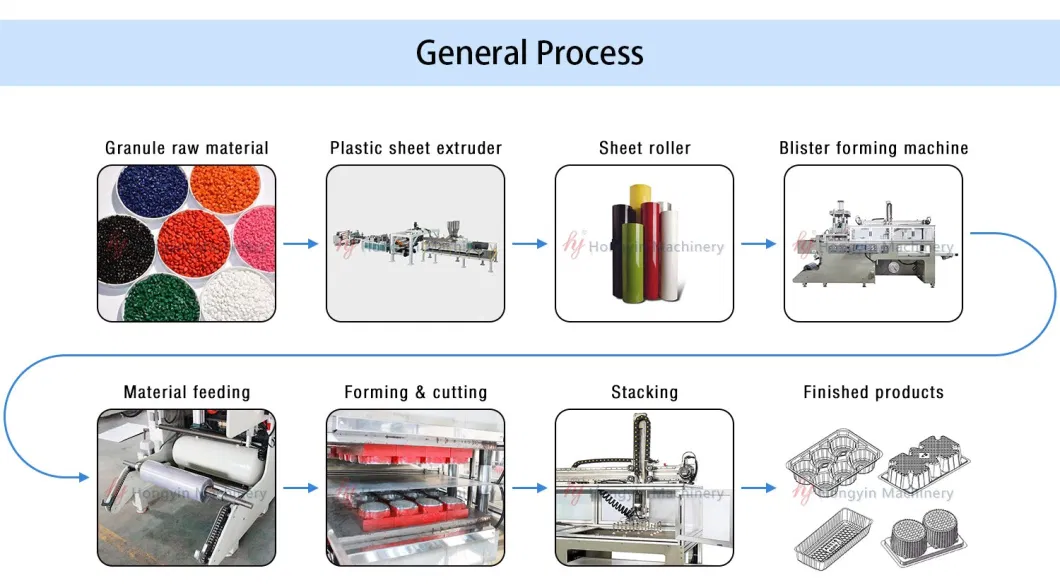

This series of machine is a plastic thermoforming equipment with integrated design of machine, electricity and gas, PLC control system, touch screen operation, sheet feeding-heating-molding-cutting - stacking one-time.

HY-70/95 is suitable for BOPS, PS, APET, PVC, PLA and other thermoplastic materials.It can form a variety of lids, boxes, dishes, trays,such as the lids of fast food box, sushi, paper bowl, aluminum foil, the trays of moon cake,pastry, supermarket,and it also can produce medical device packaging,like oral liquid tray, medicine injection tray.

Sample for reference

Parameter

| Forming Area | 700x 950 mm(27.6"x37.4" ) |

| Depth of Draw | 125mm (5") maximum |

| Knife Length | APET:12000mm / OPS:18000 mm |

| Material Thickness Range | 0.15-1.0mm (0.006"-0.040") |

| Air Pressure | 0.7Mpa |

| Air Consumption | 2000 Litres/min |

| Cooling Water Consumption | 15Litres/min |

| Power Consumption | 14kw/hr(Approximate) |

| Heating power | 38kw |

| Motor power | 13kw |

| Power Supply | AC 380V 50/60HZ |

| Working speed | 600-1200 Cycles/hr |

| Material Roll Diameter | 1000 mm(39.4")maximum |

| Sheet Width | 1000 mm(39.4")maximum |

| Machine Dimensions | 6590x1760x2720mm(259.4" x 69.3" x 107") |

| Machine Weight | 6800kg |

Features

1. Use for forming BOPS/HIPS/PS/PVC/PET plastic sheets into various of boxes, dishes, trays, bowls and lids.

1. Use for forming BOPS/HIPS/PS/PVC/PET plastic sheets into various of boxes, dishes, trays, bowls and lids.

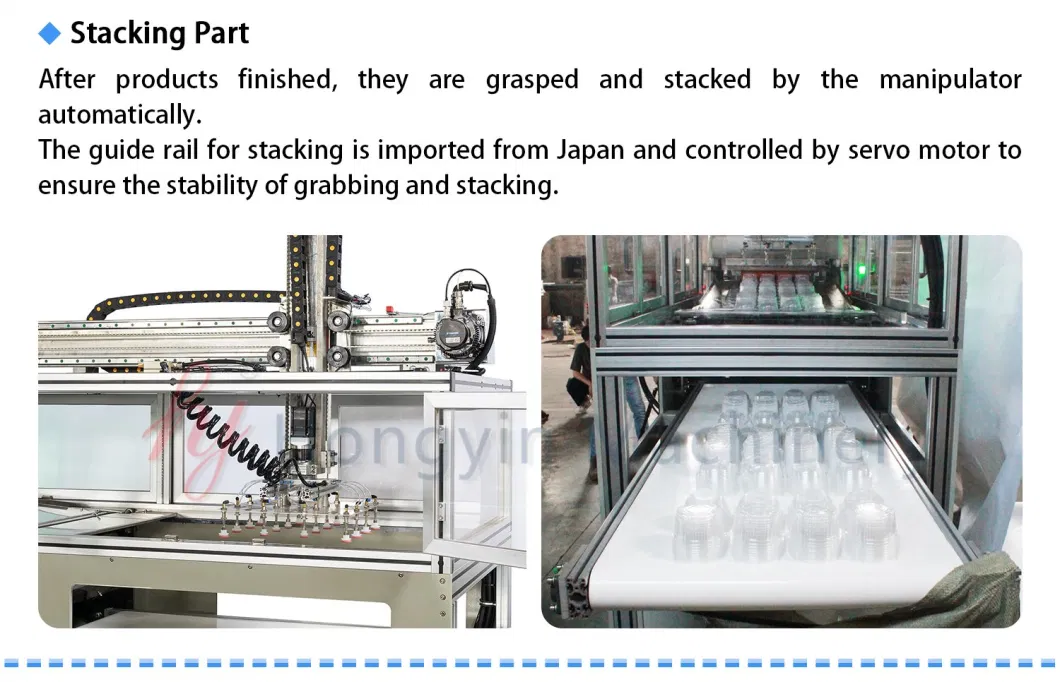

2. Combination of mechanical, electrical and pneumatic components, and it combines the material sending, heating, forming and cutting into one process. The final products already cut one by one. 3. The whole system is controlled a micro PLC, which can be operated in man-interface. And it is capability reliable, safe and jarless, less error.

4. Servo motor drives the sheet transport system.

5. Has quickly production capacity, highly utilization ratios of plastic sheet, low air consumption and maintenance, beautiful final products, so it is a new generation ideal package equipment.

6. Telecommuting and memory reserve functions.

About Service.

Q: What's your delivery date?A: Usually finish the production within 30 days after your 30% advanced payment, actually need to check according to our stock & production plan.

Q: Terms of payment?

A: We accept T/T, 30% in advance and 70% balanced against B/L copy.

We accept L/C at sight.

Q: How many days will you finish installing?

A: We will finish installation and training within 30 days.

Q: How long is your machine's warranty period?

A: All our machines have one year guarantee, starting from the finished installation.

Q: How could we do after one year warranty period?

A: We also can do service for you, if require overseas service, you need pay salary to our technician 150 USD/day.

Q: How could we do if the parts are broken within the warranty?

A: We would express the free replacement parts during the warranty date.