Basic Info.

Model NO.

HKZK400

Power

Electric

Automation

Automatic

Inflatable Device

With Inflatable Device

Type

Single Chamber Vacuum Packing Machine

Object State

Powdery, Liquid, Solid

Condition

New

Supply Ability

30 Set/Sets Per Month

Certification

CE Certificate

Material

SUS 304 Stainless Steel

Name

Vacuum Packing Machine

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

After Warranty Service

Field Maintenance and Repair Service

Service Location

Local

Dimension(L*W*H)

Customizable

Brand Name

Henco

Weight

100kg

Place of Origin

Shandong, China

Factory or Not

Factory

Voltage

380V/50Hz

Packaging Type

Bag

Applicable Industries

Food, Clothing, Home Textiles, Chemical Industry

Transport Package

Export Wooden Crates

Specification

520*520*1000mm

Trademark

Henco

Origin

China

Packaging & Delivery

Package Size

70.00cm * 70.00cm * 140.00cm

Package Gross Weight

100.000kg

Product Description

Products Show

2.The machine has vacuum pumping (inflation), vacuum sealing is completed once, and the vacuum degree is adjusted by the time potentiometer setting switch.

3.The sealing temperature is divided into five levels to adjust, the transformer heating voltage to achieve different sealing temperatures, and the heat sealing time is controlled by digital display time relay.

4.The shell is made of stainless steel, and the control panel adopts a new touch mode button.

Specification

The scope of application

Core component display

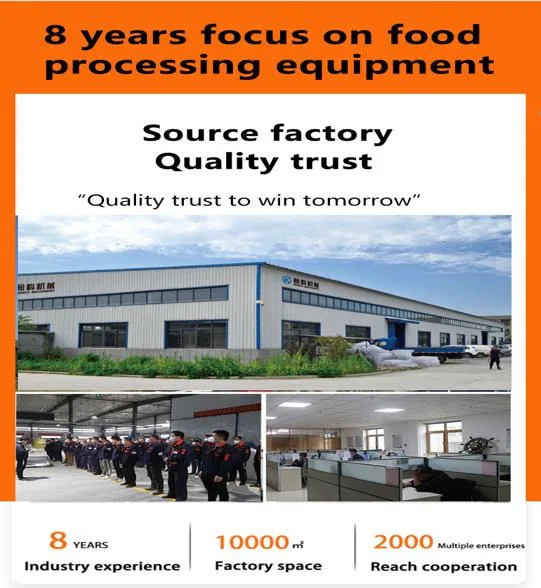

Company

About us

Jinan Henco Machinery Co., Ltd, located in the famous Spring City-Jinan city, Shandong Province.We are a professional manufacturer of processing machinery in the application of meat food processing. Our product includes Slicer Machine, Cutter Machine, Automatic Burger Former, Batter, Preduster, Bread machines, Flouring machine,and related machines. And we can improve and upgrade our technique according to our clients.Slicer Machine and Cutter Machine are awarded the authorization of "Patent and CE".The company insists on "Build Quality Attentively, Create the Future Service." Now, our company has lots of excellent technical talents, a mature client group, perfect after-sale staff. Keep high quality, reasonable price to let customers satisfy for our product.Jinan Henco looking forward to your further cooperation.

HENCO BIG THINGS RECORD

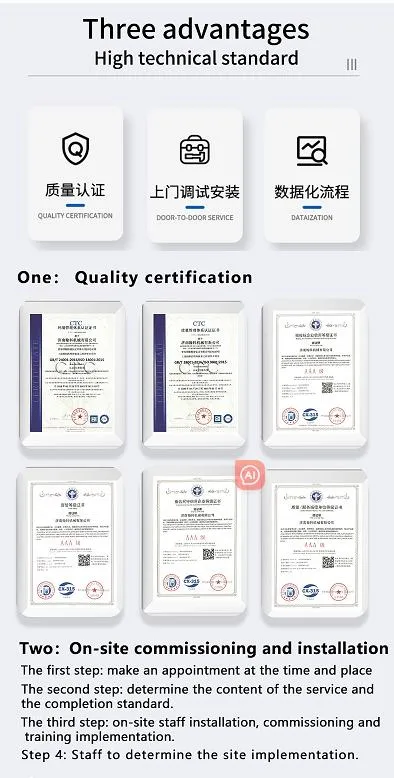

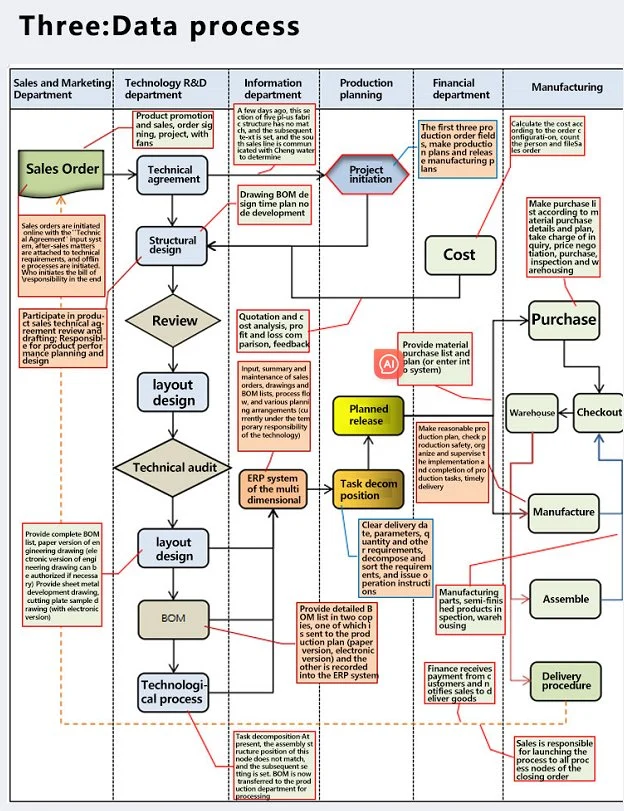

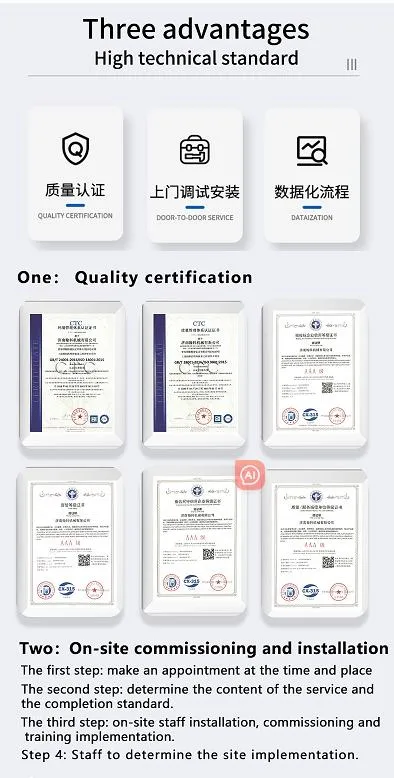

Three advantages

Quality certification

On-site commissioning and installation

The first step: make an appointment at the time and place

The second step: determine the content of the service and the completion standard

The third step: on-site staff installation, commissioning and training implementation

The fourth step: Staff to determine the site implementation

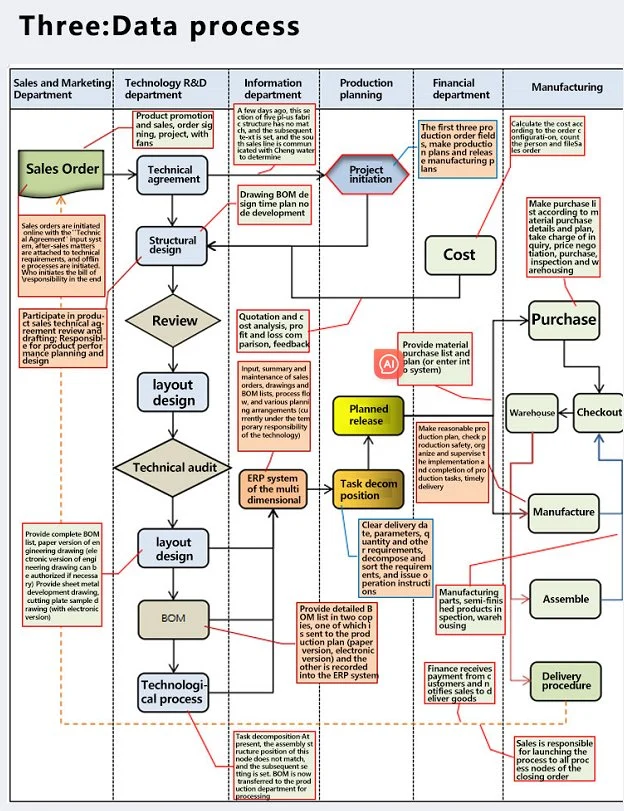

FOOD PROCESSING SYSTEM SOLUTION

Jinan Henco Machinery Co.,Ltd keeps improving food processing machines' function and quality level to

accelerate our clients' production, to make food industry better, to achieve our social value. After recent years' development, Jinan Henco Machinery Co.,ltd has gained widespread reputation with advanced echnology and professional processing equipments.

Perfect service system

Super high quality control

Food processing machinery manufacturers

Quality to win the market integrity cast cooperation

Quality trust to win tomorrow

Speak with authority quality assurance is trustworthy.

Service&Support

INSTALLATION & COMMISSIONING

Industry new product development. Product program testing. Product process optimization.

TRAINING

Theory is combined with practice. Operation training, process training, maintenance training. Good for hr training center, customer site.

Equipment operators, production line management personnel, maintenance personnel. You can send personnel to our company for training, and we will display the experimental center, simulate production line operation, and conduct all- round training in combination with theory and practice. Or we can send engineers to your production site for training.

MAINTENANCE

7 X 24 all-weather standby, comprehensive and quick service. Remote solution problems can be solved by telephone, video and other network means to solve the small problems in production. Dispatch service engineers to solve the equipment failure which cannot be solved remotely, and dispatch service engineers to troubleshoot the equipment on site.

Packing and Shipping

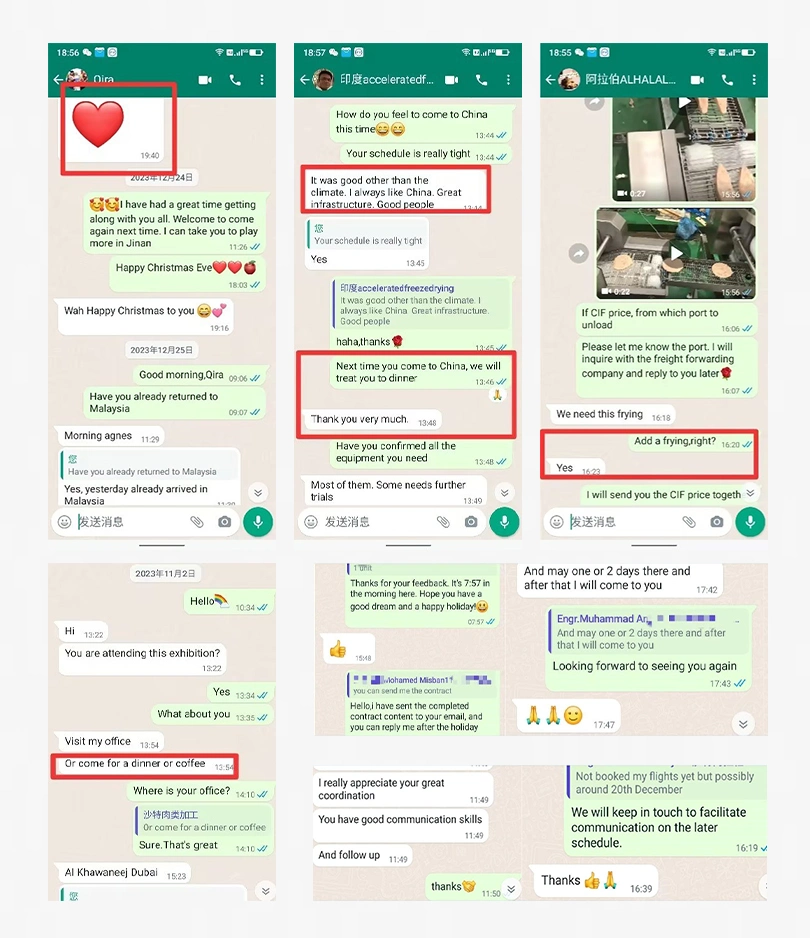

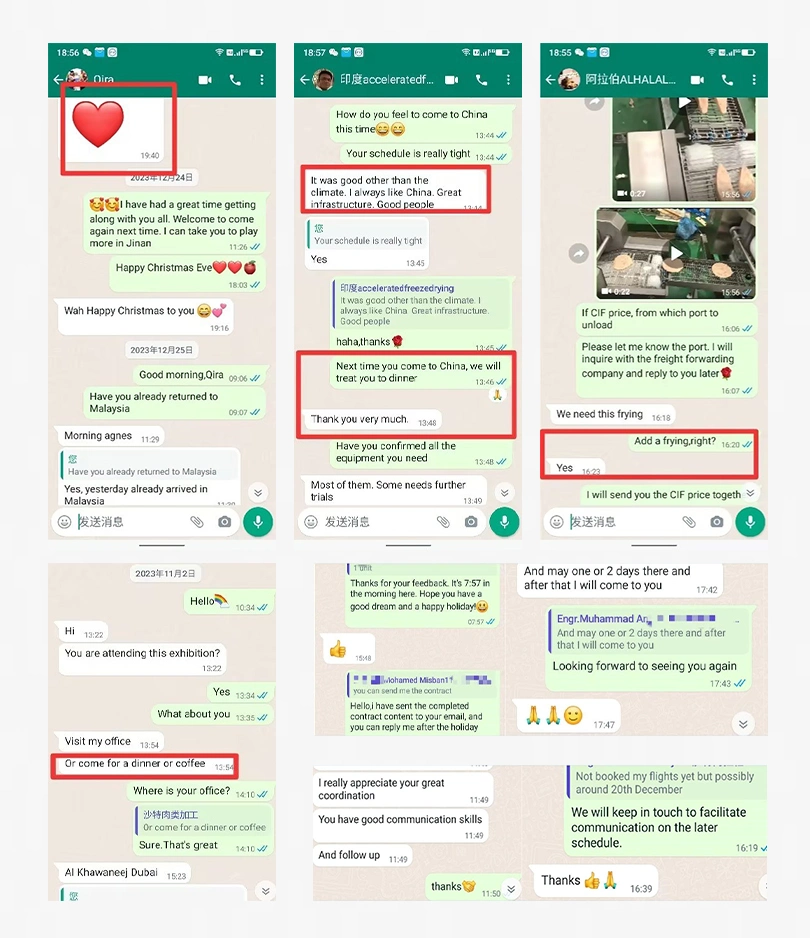

Customer Visit

Client Case

FAQ

1. Are you a factory or trading company?

We are the manufacturer and we have morethan10 years factory experience.As only the machine made by ourself,quality can be trusted,and most important thing is we can do better service after sales.we know how to fix the problem in each parts easliy.so welcome to visit to our factory

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

3. How should I pay for my order? what is the procession of this purchase?

You can do 30% prepayment at first, then we will start to make production.

when the machine is ready , we will take pictures to you, and then you can do the balance.

after we got your payment. We will send the machine to you.

4. How about your service after sales? Can your engineer speak fluent english?

We offer the service from you got the machine,including how to install the machine,

how to use machine. how to let machine work.and so on. usually we will teach you how to do by emailor by skype.our engineer has many years of experience for cnc machine service.he can speak very goodenglish,so he can slove the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by client.

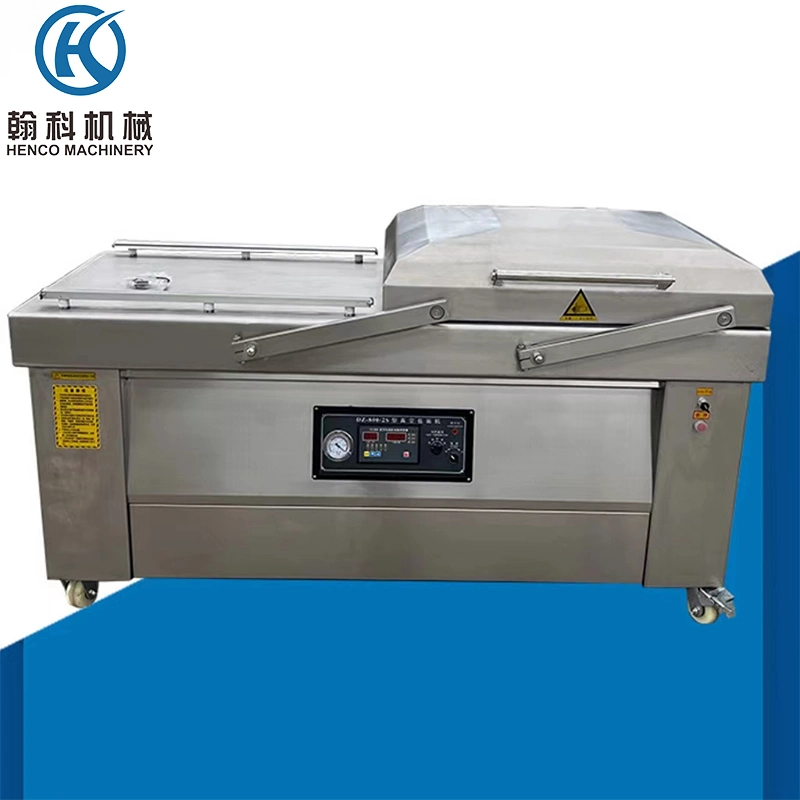

Product Description

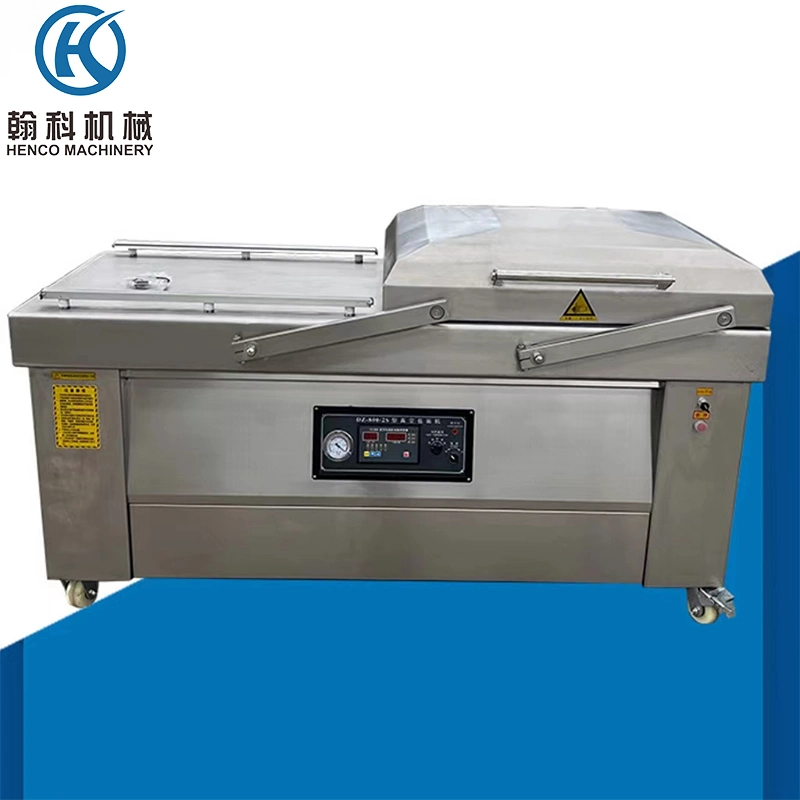

Double-Chamber Vacuum Packing Machine

Features

1. This machine is suitable for the food industry meat, sauce products, condiments, preserved fruit, grain, soybean products, chemicals, medicinal materials and other particles, powder, liquid and other commodities after vacuum filled with inert gas packaging, can prevent products from oxidation mildew, corruption, moisture, to extend the storage period of products.2.The machine has vacuum pumping (inflation), vacuum sealing is completed once, and the vacuum degree is adjusted by the time potentiometer setting switch.

3.The sealing temperature is divided into five levels to adjust, the transformer heating voltage to achieve different sealing temperatures, and the heat sealing time is controlled by digital display time relay.

4.The shell is made of stainless steel, and the control panel adopts a new touch mode button.

Specification

| Model | HKZK400 |

| Vacuum chamber size | 500 *460*120mm |

| Packing Capacity | 120 times/hour |

| Seal dimensions | 400 x 10mm/2 pieces |

| Overall dimensions | 520*520*1000mm |

| Seal spacing | 400mm |

| Weight | 100kg |

| Power | 2.2kw |

| Model | HKZK600 |

| Vacuum chamber size | 920 *780*200mm |

| Packing Capacity | 120 times/hour |

| Seal dimensions | 800 x 10mm/2 pieces |

| Overall dimensions | 1830*910*1100mm |

| Seal spacing | 625mm |

| Weight | 550kg |

| Power | 4.0kw |

The scope of application

Core component display

The machine is made of high quality wear-resistant rubber made of movable casters, which can rotate 360 degrees in all directions to facilitate the handling and movement of the machine.

Panel operation is more simple, pumping, sealing, cooling time can be adjusted vacuum pumping, sealing once completed.

Thickened food grade stainless steel sheet.Good air tightness, not easy to rust.Easy to care for suitable for harsh environments.

Good vacuum effect

Vacuum preservation

Double the power efficiency

Low power consumption

Vacuum preservation

Double the power efficiency

Low power consumption

Company

About us

Jinan Henco Machinery Co., Ltd, located in the famous Spring City-Jinan city, Shandong Province.We are a professional manufacturer of processing machinery in the application of meat food processing. Our product includes Slicer Machine, Cutter Machine, Automatic Burger Former, Batter, Preduster, Bread machines, Flouring machine,and related machines. And we can improve and upgrade our technique according to our clients.Slicer Machine and Cutter Machine are awarded the authorization of "Patent and CE".The company insists on "Build Quality Attentively, Create the Future Service." Now, our company has lots of excellent technical talents, a mature client group, perfect after-sale staff. Keep high quality, reasonable price to let customers satisfy for our product.Jinan Henco looking forward to your further cooperation.

HENCO BIG THINGS RECORD

2015 ,Jinan Henco Machinery Co., Ltd was established.

2016 ,The first meat slicer was rolled out in March; in the same year, the first generation of strip cutter was put into operation .

2017 ,Moved into a new factory; started foreign trade business; In July, participated in the first overseas exhibition: Malaysia Food Machinery Exhibition; in November, participated in the Dubai Gulfood Manufacturing Food Machinery Exhibition.

2018,The pretreatment equipment such as flouring, battering and breading machines were put into production; in the same year, participated in

many domestic and foreign exhibitions .

2019,Moved to a new factory; in the same year, obtained 11 national patents; and obtained the intellectual property rights compliance certificate.

2020,Inherit and optimize the product structure, helping food companies with excellent products and high-quality services .

2021 ,Henco won the provincial high-tech enterprise, Upgraded again and moved to a new factory; Open a new chapter of HENCO development.

2022 , Henco obtained the two integration management system certification, AAA credit enterprise, add new 9 patents.

2023 ,Henco continues to move forward on the road of development and is committed to creating intelligent food project production lines..

2024 ,Continue to help food companies and realize their own corporate value.

2025, Henco in the development of the road to continue to build, committed to create intelligent food project production line, continue to help food enterprises, and realize their own enterprise value.

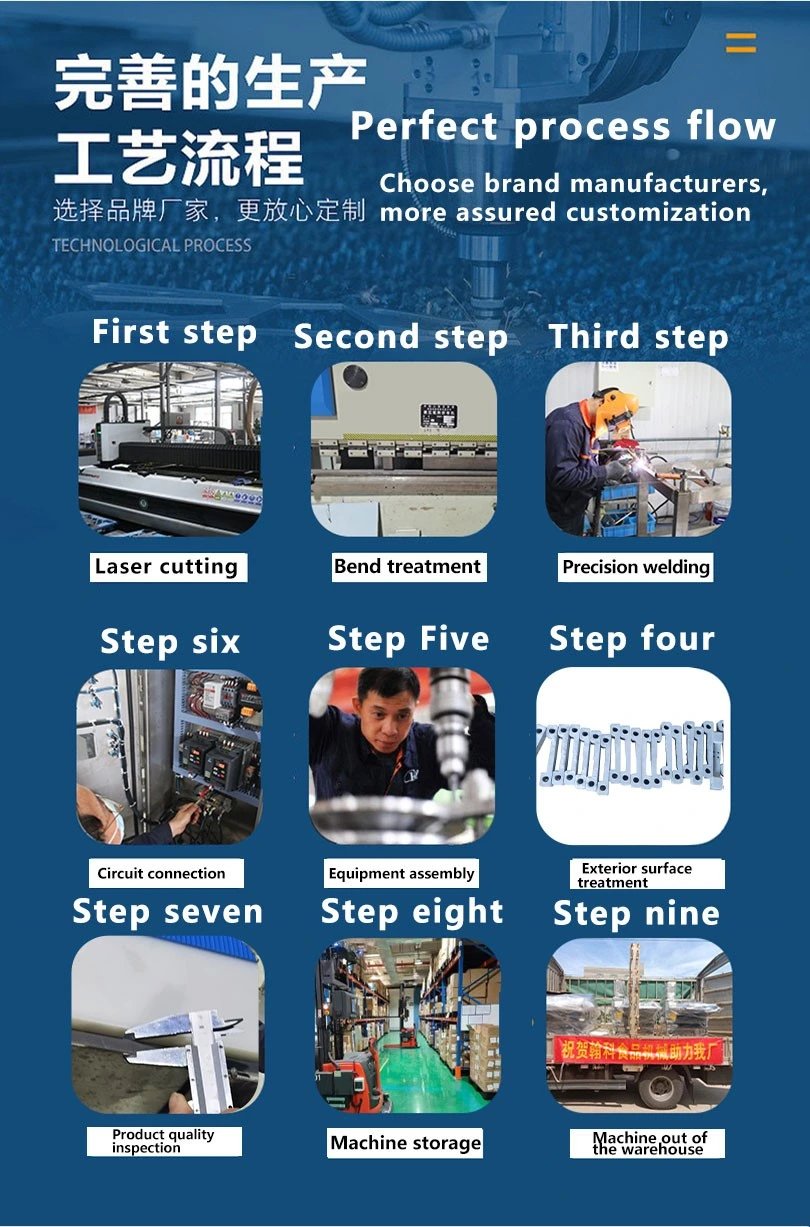

Source factory quality trust

Source factory quality trust

Three advantages

Quality certification

On-site commissioning and installation

The first step: make an appointment at the time and place

The second step: determine the content of the service and the completion standard

The third step: on-site staff installation, commissioning and training implementation

The fourth step: Staff to determine the site implementation

FOOD PROCESSING SYSTEM SOLUTION

Jinan Henco Machinery Co.,Ltd keeps improving food processing machines' function and quality level to

accelerate our clients' production, to make food industry better, to achieve our social value. After recent years' development, Jinan Henco Machinery Co.,ltd has gained widespread reputation with advanced echnology and professional processing equipments.

Perfect service system

Super high quality control

Food processing machinery manufacturers

Quality to win the market integrity cast cooperation

Quality trust to win tomorrow

Speak with authority quality assurance is trustworthy.

Service&Support

INSTALLATION & COMMISSIONING

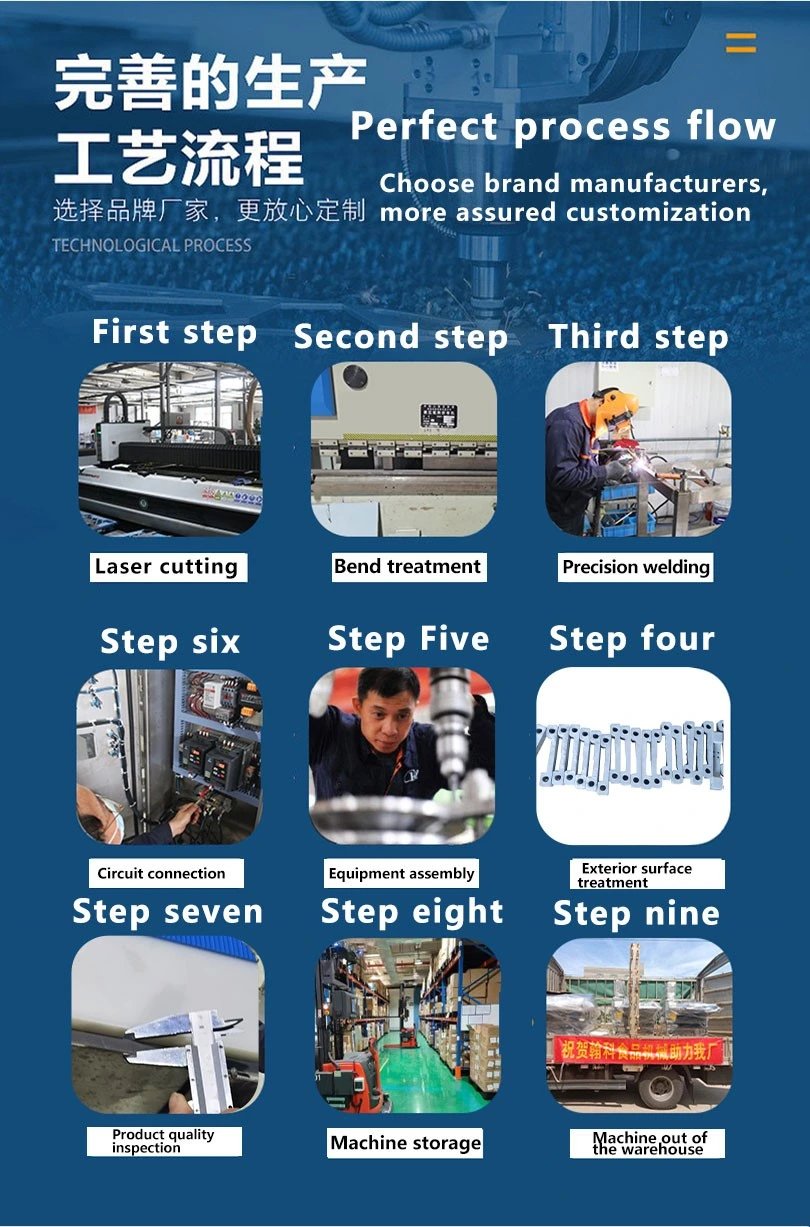

Industry new product development. Product program testing. Product process optimization.

TRAINING

Theory is combined with practice. Operation training, process training, maintenance training. Good for hr training center, customer site.

Equipment operators, production line management personnel, maintenance personnel. You can send personnel to our company for training, and we will display the experimental center, simulate production line operation, and conduct all- round training in combination with theory and practice. Or we can send engineers to your production site for training.

MAINTENANCE

7 X 24 all-weather standby, comprehensive and quick service. Remote solution problems can be solved by telephone, video and other network means to solve the small problems in production. Dispatch service engineers to solve the equipment failure which cannot be solved remotely, and dispatch service engineers to troubleshoot the equipment on site.

Packing and Shipping

Customer Visit

Client Case

FAQ

1. Are you a factory or trading company?

We are the manufacturer and we have morethan10 years factory experience.As only the machine made by ourself,quality can be trusted,and most important thing is we can do better service after sales.we know how to fix the problem in each parts easliy.so welcome to visit to our factory

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client s specific requirements, it would be 15 to 30 days.

3. How should I pay for my order? what is the procession of this purchase?

You can do 30% prepayment at first, then we will start to make production.

when the machine is ready , we will take pictures to you, and then you can do the balance.

after we got your payment. We will send the machine to you.

4. How about your service after sales? Can your engineer speak fluent english?

We offer the service from you got the machine,including how to install the machine,

how to use machine. how to let machine work.and so on. usually we will teach you how to do by emailor by skype.our engineer has many years of experience for cnc machine service.he can speak very goodenglish,so he can slove the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List,

Commercial Invoice, B/L, and other certificates as required by client.