Basic Info.

Model NO.

HC-G200

Application

Cleaning, Detergent, Cosmetics, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning

Type

Filling and Sealing Machine

Forming Species

Bag Moulding

Forming Function

Filling, Seal

Driven Type

Electric

Material Type

Powder

Packaging

Bag

Packaging Material

Plastic

MOQ

1 Set

Material

SUS304

Voltage

380 V

Packaging Type

Premade Bag

Bag Feeding

Automatically Picking up

Suitable Material

Powder / Liquid/Sauce /Granules/Oil

Bags Type

Stand up Pouch with Zipper or Spout, Flat Bag

Bag Size Range

Check The Size Range of Each Model Followed

Optional Function

Hole Punching, Netorgen Fill

Bag Open

Vacuum Open

Bag Open Detect

Vacuum or Sensors

Bag Open Rate

99%, No Bag Open, No Fill and Seal

Transport Package

Plywood Case

Specification

1950*1400*1520mm

Trademark

Grepack

Origin

China

HS Code

8422303090

Production Capacity

30 Sets Per Month

Product Description

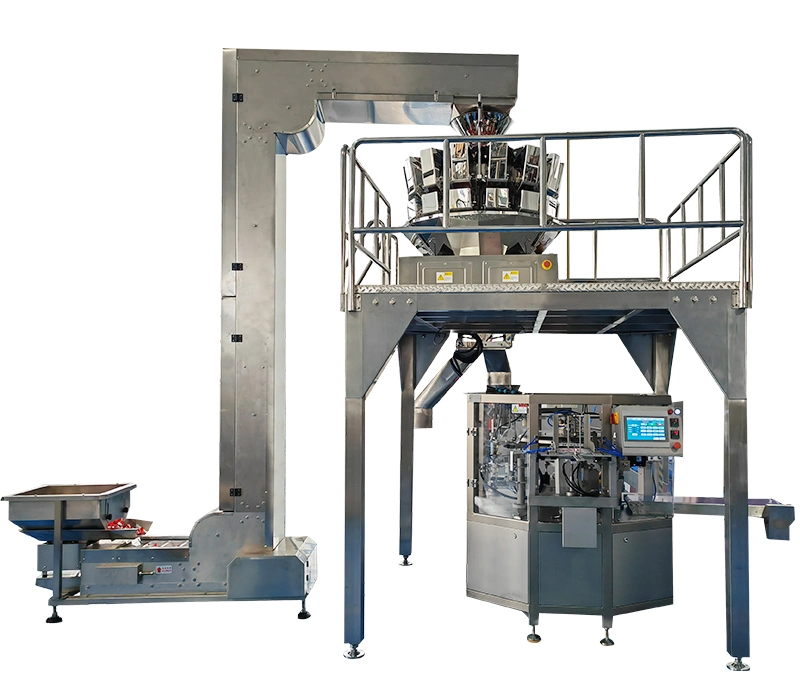

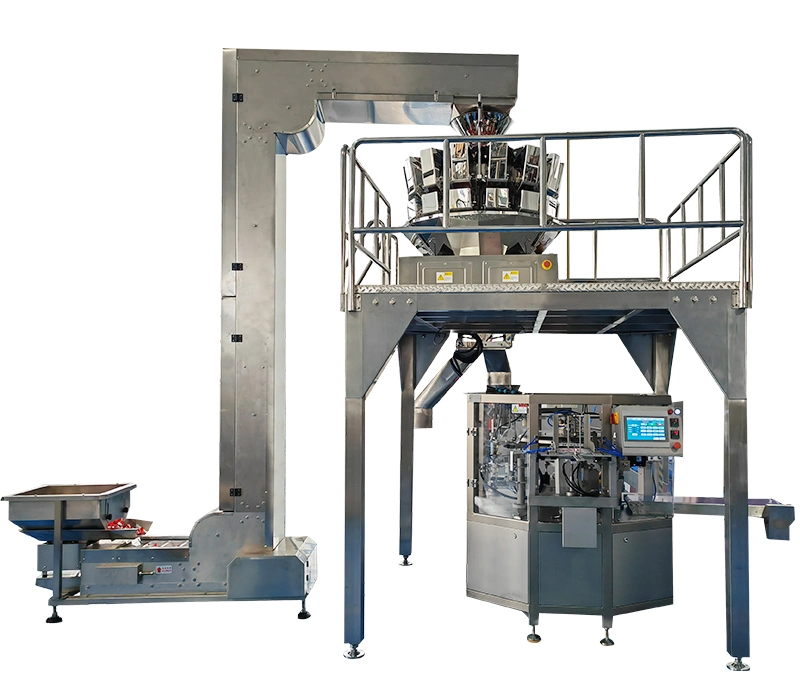

Rotary Premade Bag Packaging Machine

Rotary Premade Bag Packaging Machine The machine is an automatic rotary premade pouch packing machine for premade bags with or without zipper. It can meet the requirment which needs different specifications, big or small volume but small capacity. It can not only pack 3-side or 4-side sealed bag, but even also bags with hanging hole, standing pouches and shaped bags and doypack bag with corner spout etc. It is applicable of powder,granule,liquid,paste and blocks etc by using different measuring devices. It is convenient to switch the packing type .

Features:

1. The whole machine is a 8- stations structure, and its operation is controlled by PLC (with motion function) and large screen touch centralized control, simple and convenient operation.

2. It is equipped with automatic fault tracking and alarm system to display the operation status in real time.

3. The empty bag tracking detection device realizes no bag opening, no blanking and no sealing.

4. The action execution adopts full servo control system, which is reliable, fast and accurate.

5. The design of the whole machine complies with GMP standards and has passed CE certification.

Parameters

1. The whole machine is a 8- stations structure, and its operation is controlled by PLC (with motion function) and large screen touch centralized control, simple and convenient operation.

2. It is equipped with automatic fault tracking and alarm system to display the operation status in real time.

3. The empty bag tracking detection device realizes no bag opening, no blanking and no sealing.

4. The action execution adopts full servo control system, which is reliable, fast and accurate.

5. The design of the whole machine complies with GMP standards and has passed CE certification.

Parameters

| MODEL | HC-G200 | HC-G250 | HC-G300 |

| Packing speed | 82bag/min | 70bag/min | 60bag/min |

| Applicable bag width | 90-200mm | 130-250mm | 160-300mm |

| Applicable bag height | 150-360mm | 150-400mm | 150-400mm |

| Compressed air consumption | 5-7kg/CM2 500L/min | ||

| bag style | prefab bag(Flat bags, stand-up bags, zipper bags, tote bags, M-shaped bags, etc.) | prefab bag(Flat bag, stand-up bag, zipper bag, tote bag, M-shaped bag, etc.) | prefab bag(Flat bag, stand-up bag, zipper bag, tote bag, M-shaped bag, etc.) |

| Packaging Materials | Single-layer PE, PE composite film, paper film and other various composite films | ||

| Total Weight | 700kg | 700kg | 700kg |

| voltage | AC380V 50Hz | ||

| total power | 7KW | ||

| Dimensions | 1950X1400X1520mm | 2100X1500X1520mm | |

Shanghai Grepack Packing Machinery Co., Ltd., founded in 2002, is a professional intelligent packaging equipment manufacturer integrating research, development, and production. The company has developed unmanned intelligent packaging products, such as an automatic bottling production line (including unscrambler, filling, capping, labeling, carton erector, carton packing machine, carton sealing machine, palletizer ); Bag automatic production line(including:bag-marking, filling, sealing, carton erector, carton packer, carton sealer, and palletizer).

Shanghai Grepack Packing Machinery Co., Ltd., founded in 2002, is a professional intelligent packaging equipment manufacturer integrating research, development, and production. The company has developed unmanned intelligent packaging products, such as an automatic bottling production line (including unscrambler, filling, capping, labeling, carton erector, carton packing machine, carton sealing machine, palletizer ); Bag automatic production line(including:bag-marking, filling, sealing, carton erector, carton packer, carton sealer, and palletizer).