Basic Info.

Model NO.

MZ-350B

Max Width of Roll Film

Max.320mm

Packing Speed

40-230bag/Min

Voltage

220V,50/60Hz

Machine Size(L*W*H)

4090*680*1420mm

Machine Weight

500kgs

Packing Sample

Biscuits

Servo Motor

3 Servo

Power

2.4kw

Packing Film

OPP,Aluminized

Origine

Shanghai

Spart Partss

Brusher

Transport Package

Exported Wooden Case Plywood

Specification

MZ-250B

Trademark

SME

Origin

Shanghai

HS Code

8422303090

Production Capacity

800 Pieces/Month

Product Description

Servo Motor Drive Horizontal Packing Machine

1. Machine Picture

2.USES

Horizontal Automatic Flow Pack Packing Machine is suitable for packaging various kinds of large size regular objects into pillow bag or gusseted bag, like Food, Vegetables and Fruits, Hardwares, Hotel Supplies, Stationary, Electric Products, Medical, Daily use and etc

Food: bakery bread,biscuits,cookies,candy,chocolate bar,cake,popsicle,ice cream bar,meat,muffin,sausage,noodles,beef jerky,egg roll,etc.

Vegetables and Fruits: apples,bananas,lettuce,potatoes,tomatoes,peppers,cucumbers,etc.

Hardwares: hinge,stainless steel pipe,bearings,screw,nuts and washer,etc

Hotel Supplies: soap,disposable comb,razor,toothpaste and toothbrush in one set.

Stationary: pencil,eraser,notebook,paper card,adhensive tape,etc.

Electric Products: battery,usb cable,earphone,user manual and accessories in one set.

Medical: face mask,glove,gauze,pill capsule table,disposable syringe,bandage,etc.

Daily use: disposable tableware,knife,spoon,fork,plate,sponge,scourer,wipes,several drinking straws in a bag,plastic cups,bottles,wood charcoal briquette,napkin,baby diaper,etc.

3. Sample

4. Performance Characteristics

1. Compact mechanical structure design, 3 servo motors control, stable running, easy repair and maintenance, less breakdown and low noise.

2. With super intelligent touch screen and individual digital display temperature control system, it is simple to set parameters and convenient to change product size.

3. Brand color code photo sensor tracking system is available to ensure accurate sealing, cutting position and high control accuracy.

4. Rational electrical design for simple control, improving stability.

5. Simplified mechanical structure design for simple adjustment, improving production efficiency.

5. Main Technical Parameter

Optional Accessories:

Function: It can print Manufacture date,Expiration date and Batch number on the bag

6. Main Electrical Brand

7. Machine Details:

8.Packing Materials:

Heat-sealable laminated film: such as OPP,Aluminized,POPP& other special sealable packing film

9. Spart PartsS

1. Three pushers

2. A Mid-seal belt

3. A solid-state relay

4. Two heating tubes

5. One set tools

6. User manuels

7.Four foot cups

8.One set power cable.

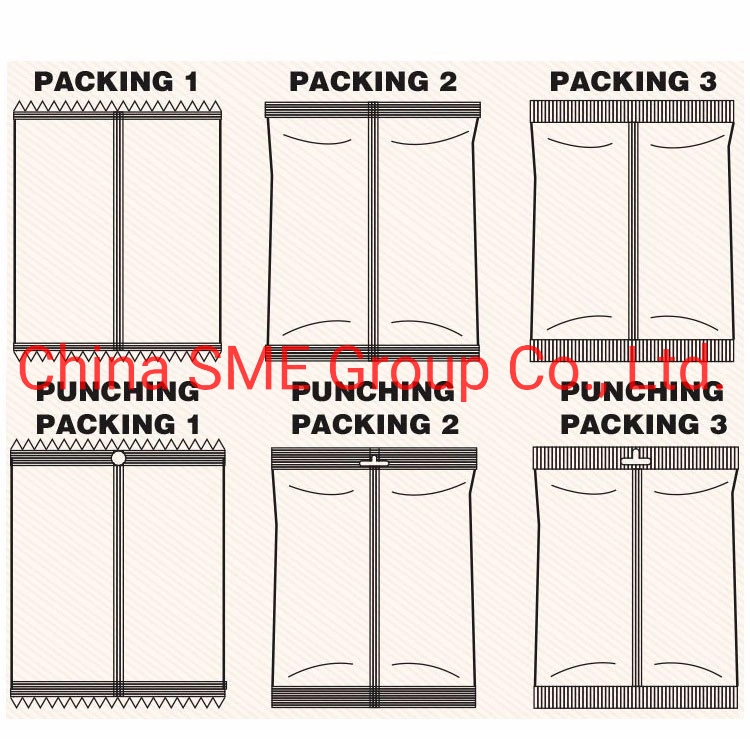

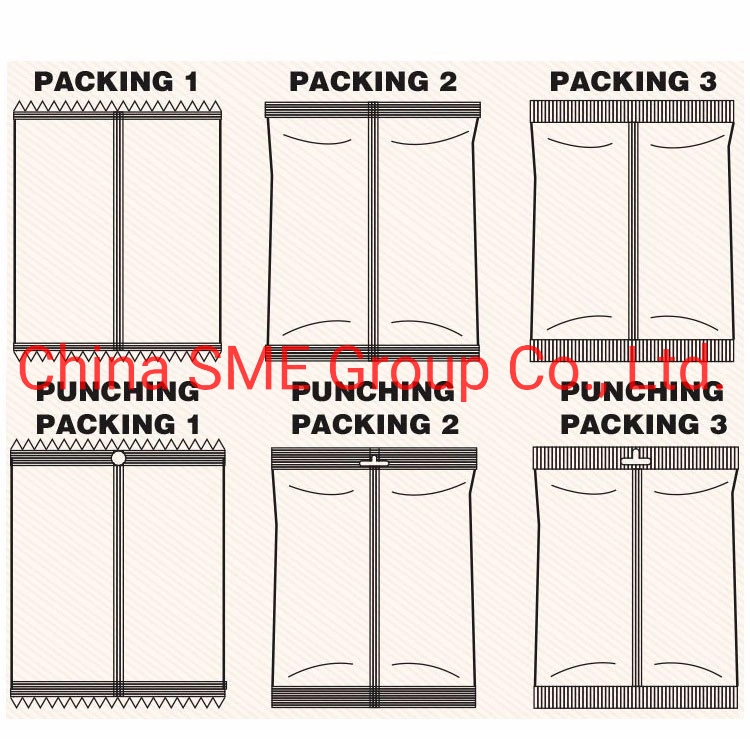

10. Bag Type

11. Packing Method

11. Packing Method

Exporting Wooden Cases: 1 machine with 2 wooden boxes

12.Our Client :

Our Certification:

About US:

SME is a leading manufacturer in the field of front-of-line packaging devices since 2008. In the past 10 years, MOTECH has targeted on the technology development, precise manufacturing, professional marketing, satisfied technical support and OEM solutions. We offer Flow Packing Machine;Vertical Packing Machine;Metal Detector;Weight Checker and Weighter to fit the needs of different industries.

Due to continuous efforts in the field of end-of-line packaging devices, MOTECH Machinery was honored to obtain CE certificate and ISO 9001 certificate showed our emphasis on safety ,quality and has a successful sale in Asia, American, Africa and so on. MOTECH looks forward to establishing a long-term and mutual beneficial partnership with more agents or distributors all over the world. Moreover, We provide the OEM solution based on strict quality control for famous companies in Japan, USA etc.

In the future, MOTECH Machinery will keep to provide customers:

-Quality machines

-Competitive price

-Satisfied service

Our Team:

1. Machine Picture

2.USES

Horizontal Automatic Flow Pack Packing Machine is suitable for packaging various kinds of large size regular objects into pillow bag or gusseted bag, like Food, Vegetables and Fruits, Hardwares, Hotel Supplies, Stationary, Electric Products, Medical, Daily use and etc

Food: bakery bread,biscuits,cookies,candy,chocolate bar,cake,popsicle,ice cream bar,meat,muffin,sausage,noodles,beef jerky,egg roll,etc.

Vegetables and Fruits: apples,bananas,lettuce,potatoes,tomatoes,peppers,cucumbers,etc.

Hardwares: hinge,stainless steel pipe,bearings,screw,nuts and washer,etc

Hotel Supplies: soap,disposable comb,razor,toothpaste and toothbrush in one set.

Stationary: pencil,eraser,notebook,paper card,adhensive tape,etc.

Electric Products: battery,usb cable,earphone,user manual and accessories in one set.

Medical: face mask,glove,gauze,pill capsule table,disposable syringe,bandage,etc.

Daily use: disposable tableware,knife,spoon,fork,plate,sponge,scourer,wipes,several drinking straws in a bag,plastic cups,bottles,wood charcoal briquette,napkin,baby diaper,etc.

3. Sample

4. Performance Characteristics

1. Compact mechanical structure design, 3 servo motors control, stable running, easy repair and maintenance, less breakdown and low noise.

2. With super intelligent touch screen and individual digital display temperature control system, it is simple to set parameters and convenient to change product size.

3. Brand color code photo sensor tracking system is available to ensure accurate sealing, cutting position and high control accuracy.

4. Rational electrical design for simple control, improving stability.

5. Simplified mechanical structure design for simple adjustment, improving production efficiency.

5. Main Technical Parameter

| Type | MZ-250BS | MZ-320BS | MZ-350BS | MZ-400BS | MZ-450B S | MZ-600BS |

| Film Width | Max.250MM | Max.320MM | Max.350MM | Max.400MM | Max.450MM | Max.600MM |

| Bag Length | / | / | / | / | / | / |

| Bag Width | 30-110mm | 30-150mm | 50-160mm | 50-180mm | 50-200mm | 80-270mm |

| Products High | max.40mm | max.40mm | max.45mm | max.65mm | max.80mm | max.80mm |

| Packing Speed | 40-230bag/min | 40-230bag/min | 40-230bag/min | 40-230bag/min | 30-150bag/min | 20-80bag/min |

| Power | 220V 50/60HZ 2.4KW | 220V 50/60HZ 2.6KW | 220V 50/60HZ 2.6KW | 220V 50/60HZ 2.8KW | 220V 50/60HZ 2.8KW | 220V 50/60HZ 3.2KW |

| Machine Size(mm) | 3770x670x1450 | 3770x670x1450 | 4020x770x1450 | 4020x800x1450 | 4020x800x1450 | 4380x800x1450 |

| Machine Weight | 500kg | 550kg | 580kg | 600kg | 700kg | 850kg |

Optional Accessories:

- Air Filling Device

- Date Coder

- Angle Folding Device

- Hole Punching Device

- Magazine Filling Machine

- Alcohol Spraying Device

- Deoxidizer Chute Device

- Nitrogen Flushing Device

- Notch and Auto Labeling Machine

- Alternative Sealing Machine

- Cutting Device

Function: It can print Manufacture date,Expiration date and Batch number on the bag

6. Main Electrical Brand

| 1.PLC Panasonic from Japan | |

| 2.Inverter Panasonic from Japan | |

| 3.Close to Switch Omron from Japan | |

| 4.Switch Button Sch-neider from German | |

| 5.Terminals Wade Miller from German | |

| 6.Display Screen WeiLun from TaiWan | |

| 7.Motor Jiangcheng from Guangdong | |

| 8.Photocell Yetai from Taiyan | |

| 9.Temperature Control List Omron from Japan | |

| 10.Pushbutton Switch Sch-neider from German | |

| 11.Power Ming Wei from Taiwan | |

| 12.Solid State Relay Sch-neider from German | |

| 13.Intermediate Relay Omron from Japan | |

| 14.Two Wire Switch Sch-neider from German | |

7. Machine Details:

8.Packing Materials:

Heat-sealable laminated film: such as OPP,Aluminized,POPP& other special sealable packing film

9. Spart PartsS

1. Three pushers

2. A Mid-seal belt

3. A solid-state relay

4. Two heating tubes

5. One set tools

6. User manuels

7.Four foot cups

8.One set power cable.

10. Bag Type

11. Packing Method

11. Packing Method Exporting Wooden Cases: 1 machine with 2 wooden boxes

12.Our Client :

Our Certification:

About US:

SME is a leading manufacturer in the field of front-of-line packaging devices since 2008. In the past 10 years, MOTECH has targeted on the technology development, precise manufacturing, professional marketing, satisfied technical support and OEM solutions. We offer Flow Packing Machine;Vertical Packing Machine;Metal Detector;Weight Checker and Weighter to fit the needs of different industries.

Due to continuous efforts in the field of end-of-line packaging devices, MOTECH Machinery was honored to obtain CE certificate and ISO 9001 certificate showed our emphasis on safety ,quality and has a successful sale in Asia, American, Africa and so on. MOTECH looks forward to establishing a long-term and mutual beneficial partnership with more agents or distributors all over the world. Moreover, We provide the OEM solution based on strict quality control for famous companies in Japan, USA etc.

In the future, MOTECH Machinery will keep to provide customers:

-Quality machines

-Competitive price

-Satisfied service

Our Team: