- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Company Profile

- Packaging & Shipping

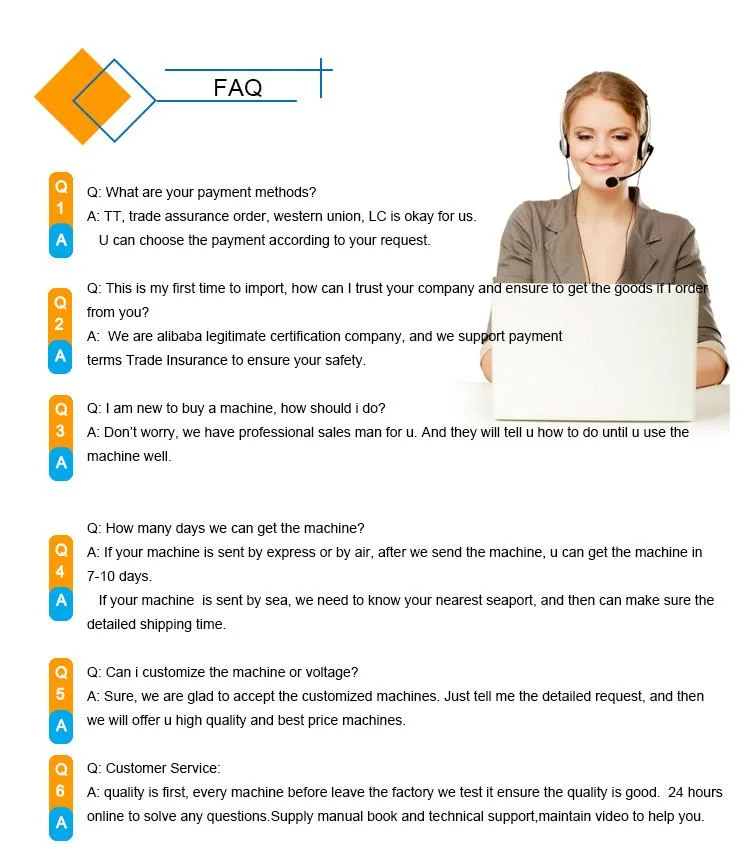

- FAQ

Basic Info.

Product Description

This fresh-keeping plastic sealing machine adopts a microcomputer operating system, and has the ability to vacuum and seal twice. It can vacuum and seal for different packaging materials and packaging requirements for cooling, air intake and opening of the cover, and the whole process is automatically controlled. The machine is equipped with vacuum degree heat sealing time and other adjustment devices to achieve the ideal packaging effect. According to the requirements of users, it can be equipped with a printing device that is easy to change and clear, that is, when the seal is sealed, the expiration date or factory number is printed on the sealing line to comply with the provisions of the national food labeling law.

This fresh-keeping plastic sealing machine has two real enterprise rooms that work in turn. The vacuum chamber is made of stainless steel. The upper and lower studios are all made of stainless steel. The overall structure is reasonable. The air port is good, beautiful and durable, and conforms to food hygiene and 1 square corner. There is a set of hot press seals that should be installed in the channel, and adopt a balanced structure to stay at any position and have a slow protection. The items after the empty packaging can prevent oxidation, and the moldy frog can be exposed to moisture to extend the product storage period.

Features of the fresh-keeping plastic sealing machine:

1. The fresh-keeping plastic sealing machine is made of 304 stainless steel with a thickness of 3mm. The control panel is controlled by a time relay. The operation is simple and convenient. The time can be adjusted according to different packaging requirements and different packaging materials. You only need to press the vacuum chamber cover when working. Complete the whole process of vacuum packaging according to automatic procedures.

2. This fresh-keeping plastic sealing machine adopts a dedicated 63 type vacuum pump, and the vacuum degree reaches the national requirement.

3. The fresh-keeping plastic sealing machine has a water removal function, which can effectively protect the vacuum pump and prolong the service life of the equipment.

4. The circuit system is sealed to avoid water splashing into the electrical system and causing malfunctions.

5. This fresh-keeping plastic sealing machine has the characteristics of complete functions, stable and reliable performance, wide application range, good sealing strength, convenient use and maintenance, etc. It is an ideal vacuum packaging machine at present.

| Model | ADZ-800 | ADZ-600 | ADZ-680 | ADZ-500 |

| seal size | 800*10/2mm | 600*10/2mm | 680*10/2mm | 600*4*8/10mm |

| Power | 6.5KW | 5KW | 3.5KW | 2.2KW |

| Vacuum chamber size | 920*780*220mm | 690*620*160mm | 800*635*135mm | 720*620*90mm |

| Packing capacity | 2~5 times/min | 2~4 times/min | 2~4 times/min | 3~5 times/min |

| Voltage | 380V 50HZ | 380V 50HZ | 380V 50HZ | 380V 50HZ |

| Number of vacuum pumps | Double pump | Double pump | Double pump | Double pump |

| Dimension | 1835*910*1060mm | 1400*720*950mm | 1580*755*920mm | 1420*800*950mm |

| The vacuum pump is an environmental protection pump imported from Germany, with less oil fume, low noise, high power and long service life in the production process. | Using smart panel microcomputer control, more simple and flexible |

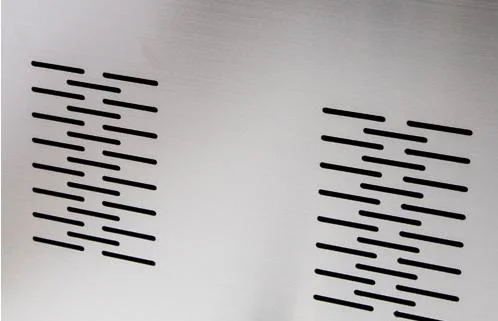

| Using high-quality rubber strips, the machine is heated evenly and quickly | Multiple cooling holes, effectively extending the life of the vacuum pump |