Basic Info.

Model NO.

DXDF-900D

Type

Packaging Production Line

Function

Sales Packing

Packaging Technology

Mildew Proof Packaging

Application

Drinks, Cleaning, Detergent, Cosmetics, Skin Care Products, Oil, Tea, Vegetable, Fruit, Rice, Flour, Seasoning, Hair Care Products, Powder

Soft and Hardness

Flexible Package

Circulation Function

Outer Packing

Frequency of Use

Packing

Mode of Operation

Packaging of Export Products

Model

Powder Packing Machinery

Dimension

L1650*W1400*H2200mm

Weight

1500kg

Capacity of Per-Line

30-70bags/Min

Power

380V 8.5kg(3phase 4 Wires)

Bag Size

(L)50-150mm, (W)40-105mm

Max Width of Film

900mm

Transport Package

Standard Export Wooden Case

Specification

CE, GMP

Trademark

Hondon

Origin

Tianjin

HS Code

8422303090

Production Capacity

3000 PCS/Year

Product Description

Multi-lanes 4 sides sealing powder Packing Machinery (DXDF-900D)

Applications:

This machine is suitable for the packaging of powder Products, like milk powder, coffee powder, etc.

Machine Features:

1. This machine will use the auger feeding system to be feeding system. Each lane has a servo motor to control the auger. That ensures the fantastic filling and precise weight accuracy.

2. The machine main motor is Panasonic servo motor with good features, such as high efficiency, energy-saving, high starting torque and easy maintenance and easy to operate.

3. Easy manipulation.

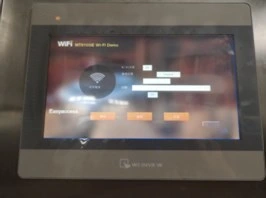

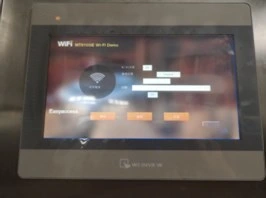

Machine operation is controlled by Touch screen with PLC system, touch screen can be set up in many languages, and PLC system can store a large number of data for machine performance

4. We have use the temperature mould to instead of the temperature meter. You can adjust the temperature on the touch screen. When the temperature is too low or too high, the machine will alarm.

5, Roller type sealing part with special designed screw thread on the surface of the sealing roller assured the seal side of the bag neat, air-tight and beautiful. The top quality high-temperature resistance, high-pressure resistance and full closed bearing area equipped at the end of the sealing roller which assured the long time and stable running of this packing machine. It no need to fill the oil.

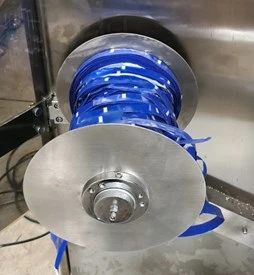

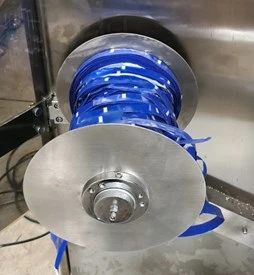

6, Slitter edge collector which can collect the slitter edge together. It's convenient for you to deal with.

7. The machine have wifi function, that means you can monitor the machine working status on your phone at anywhere and anytime.

8. Optional ribbon-tape printer device which can print the manufacture date, expiry date and lot number on the bag.

9. Vacuum conveyor is used to convey the powder material into machine hopper automatically, so you no need to climb up and fill powder into hopper manually.

Electrical parts list

Applications:

This machine is suitable for the packaging of powder Products, like milk powder, coffee powder, etc.

Machine Features:

1. This machine will use the auger feeding system to be feeding system. Each lane has a servo motor to control the auger. That ensures the fantastic filling and precise weight accuracy.

2. The machine main motor is Panasonic servo motor with good features, such as high efficiency, energy-saving, high starting torque and easy maintenance and easy to operate.

3. Easy manipulation.

Machine operation is controlled by Touch screen with PLC system, touch screen can be set up in many languages, and PLC system can store a large number of data for machine performance

4. We have use the temperature mould to instead of the temperature meter. You can adjust the temperature on the touch screen. When the temperature is too low or too high, the machine will alarm.

5, Roller type sealing part with special designed screw thread on the surface of the sealing roller assured the seal side of the bag neat, air-tight and beautiful. The top quality high-temperature resistance, high-pressure resistance and full closed bearing area equipped at the end of the sealing roller which assured the long time and stable running of this packing machine. It no need to fill the oil.

6, Slitter edge collector which can collect the slitter edge together. It's convenient for you to deal with.

7. The machine have wifi function, that means you can monitor the machine working status on your phone at anywhere and anytime.

8. Optional ribbon-tape printer device which can print the manufacture date, expiry date and lot number on the bag.

9. Vacuum conveyor is used to convey the powder material into machine hopper automatically, so you no need to climb up and fill powder into hopper manually.

Electrical parts list

| Name | Origin | Brand |

| AC contactor | JAPAN | FUJI |

| Protector | FRANCE | SCHNEIDER |

| Solid relay | JAPAN | OMRON |

| Emergency stop button | JAPAN | IDEC |

| Alarming | JAPAN | FUJI |

| Start/stop button | JAPAN | FUJI |

| Relay | JAPAN | IDEC |

| Approaching Sensor | JAPAN | OMRON |

| Touch screen | TAIWAN | WEINVIEW |

| PLC | JAPAN | PANASONIC |

| Servo motor | JAPAN | PANASONIC |

| Air cylinder | TAIWAN | AirTac |