Basic Info.

Model NO.

LZ520

Material Type

Solid,Grain,Powder,Paste,Liquid

Packaging

Bag,Box,Tray,Cup,Pouch,Sachet

Packaging Material

Film

Transport Package

Strong Wooden Box

Specification

8m*1.5m*1.9m

Trademark

BEIER

Origin

China

HS Code

842240

Production Capacity

10 Sets/Month

Product Description

Introduction :

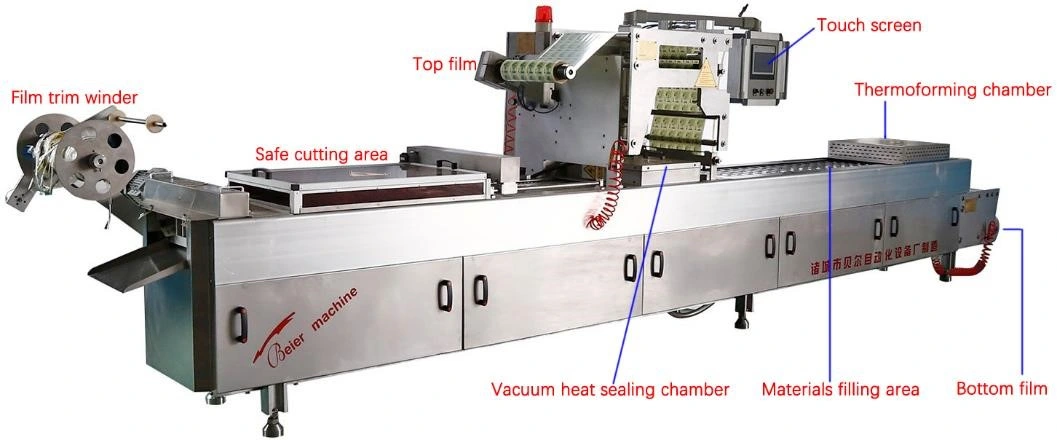

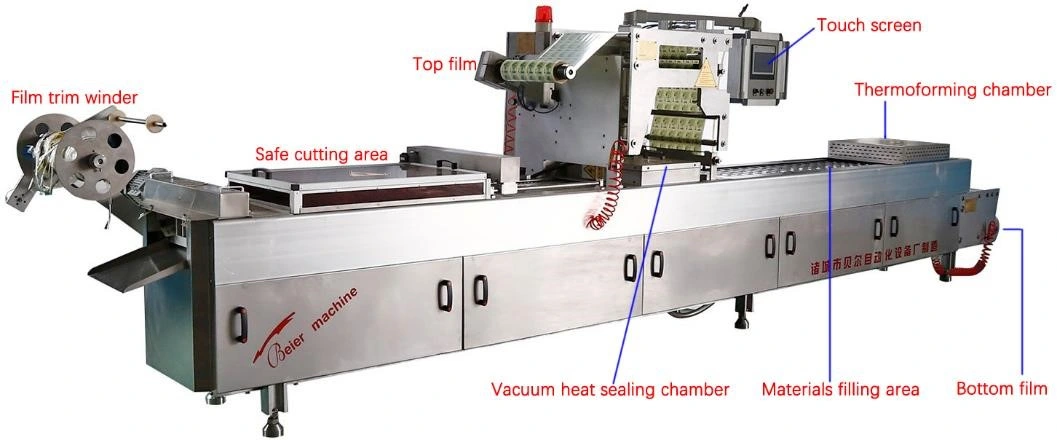

The equipment consists of two kinds of working chamber:Thermoforming chamber&Heat sealing chamber. Vacuumizing&gas-flushing jobs are finished at the same room inside the heat-sealing chamber.Packing materials are aluminium foils or a variety of films,such as: PE/CPP/PET/PP/BOPP/BOPET/POF/PVC,transparent or opaque, printed or unprinted,flexible or rigid.They will become soft and be shaped as per the die shape under heating and air pressure(positive&negative) in the forming chamber,some cases an auxiliary mould(plug) will assist the shaping process.There are two types of films/foils:Top film&bottom film according to their usages in the packing process.Generally,film thermoforming refers to the bottom film,top film is the cover.Top&bottom films will be sealed together in the heat sealing chamber. To get a more beautiful and triaxial vision of the package, the top films also can be formed into some different shapes,it is called 'Top Film Thermoforming'.The whole process is under precisely control of PLC,continuously and automatically. Our machines are only equipped with superior compoments from quality suppliers around the world to ensure a steady & highly efficient running of the machine.

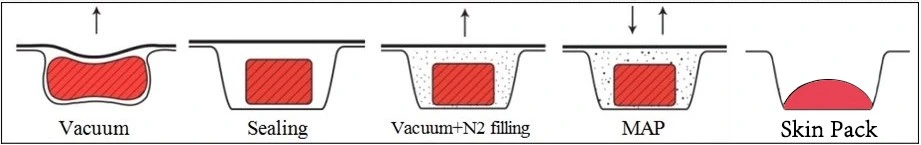

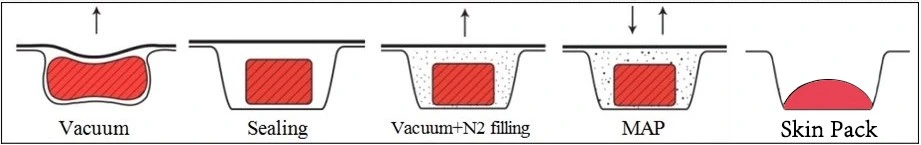

Packaging under vacuum extends the shelf life of products, since the biochemical degradation of the product is slowed down by the removal of the atmosphere. In the production of skin packs, trays and skin films are used that enclose the product tightly and seal the entire surface with the tray. In case of packs with modified atmosphere, the atmosphere in the pack is replaced with a gas mixture matched to the product in order to maintain the form,color and freshness of the product. This modified atmosphere packaging usually consists of carbon dioxide, nitrogen and oxygen.

Working principle:

(1) Top film (2) Bottom film

(3) Thermoforming chamber---The bottom film soften under heat and is shaped as per the Die(mould)'s design by combined effect of compressed air&vacuum.

(4) Loading area---Shaped cavities on the bottom film can be filled with materials manually or automatically.

(5) Sealing chamber---Air in the shaped cavities is exhausted through a vacuum tank,meantime nitrogen or another mixed atmosphere is flushed into the cavities,then the top film is applied&sealed to the bottom film under heat as per the sealing die's design.

(6) Cross cutting & longitudinal cutting units---Cutting knives separate individual packs from the sealed films.

Features:

Optional Function/Compoments:

(1) Vacuum or None vacuum

(2) Mixed gas/Nitrogen inflating

(3) Top film thermoforming.

(4) Format/Dies fast change system

(5) Nitrogen producer

(6) Inkjet printer

Technical datas

Dimensions/sizes/weight are approximate only for reference,actual cases maybe different.

Package samples:

The equipment consists of two kinds of working chamber:Thermoforming chamber&Heat sealing chamber. Vacuumizing&gas-flushing jobs are finished at the same room inside the heat-sealing chamber.Packing materials are aluminium foils or a variety of films,such as: PE/CPP/PET/PP/BOPP/BOPET/POF/PVC,transparent or opaque, printed or unprinted,flexible or rigid.They will become soft and be shaped as per the die shape under heating and air pressure(positive&negative) in the forming chamber,some cases an auxiliary mould(plug) will assist the shaping process.There are two types of films/foils:Top film&bottom film according to their usages in the packing process.Generally,film thermoforming refers to the bottom film,top film is the cover.Top&bottom films will be sealed together in the heat sealing chamber. To get a more beautiful and triaxial vision of the package, the top films also can be formed into some different shapes,it is called 'Top Film Thermoforming'.The whole process is under precisely control of PLC,continuously and automatically. Our machines are only equipped with superior compoments from quality suppliers around the world to ensure a steady & highly efficient running of the machine.

Packaging under vacuum extends the shelf life of products, since the biochemical degradation of the product is slowed down by the removal of the atmosphere. In the production of skin packs, trays and skin films are used that enclose the product tightly and seal the entire surface with the tray. In case of packs with modified atmosphere, the atmosphere in the pack is replaced with a gas mixture matched to the product in order to maintain the form,color and freshness of the product. This modified atmosphere packaging usually consists of carbon dioxide, nitrogen and oxygen.

Working principle:

(1) Top film (2) Bottom film

(3) Thermoforming chamber---The bottom film soften under heat and is shaped as per the Die(mould)'s design by combined effect of compressed air&vacuum.

(4) Loading area---Shaped cavities on the bottom film can be filled with materials manually or automatically.

(5) Sealing chamber---Air in the shaped cavities is exhausted through a vacuum tank,meantime nitrogen or another mixed atmosphere is flushed into the cavities,then the top film is applied&sealed to the bottom film under heat as per the sealing die's design.

(6) Cross cutting & longitudinal cutting units---Cutting knives separate individual packs from the sealed films.

Features:

- External high vacuum pump from Busch Germany,no pollution.

Busch Vacuum Pumps and Systems is one of the largest manufacturers of vacuum pumps in the world. Its headquarters is located in Maulburg (Germany), where the main German manufacturing facility is located. - Banner American photoelectric tracking system.

- Equipped with cooling system for heat-sealing chamber.

- Power off phase and reverse phase protection.

- Electric leakage protection, automatically cut off power supply when leakage occur, to protect safety of operators.

- Pneumatic components from AirTAC Inc, key parts (Pneumatic Festo/Vacuum valve/Valve Terminal)from Japan SMC.

- Aluminum alloy integral side plate(Patent No.ZL2004200390983),high strength good straightness,hardly to distort.

- Push-pull Siemens smart touch screen(include communication cables) and PLC.

- Film moving controller&driver made by Mitsubishi or by Siemens.

- Guide rail system of printer made by German Igus with Panasonic servo driving system.

- Maintenance-free linear bearings of the cross-cutting knife made in Germany.

- Panasonic inverter speed-regulating system(include communication cables).

- Temperature sensors and controllers made by Siemens Germany or made by Omron Japan.

- Stainless steel chain from REGINA Italy.

- Pneumatic tensioning mechanism, pneumatic brake, prestress adjustable for both top and bottom film.

- Equipped with film deviation automatic correcting system.

- Equipped with film tension regulating system, the computer can automatically identify the sizes of rollers, automatically adjust tension to keep the same stress of upper and lower films.

Optional Function/Compoments:

(1) Vacuum or None vacuum

(2) Mixed gas/Nitrogen inflating

(3) Top film thermoforming.

(4) Format/Dies fast change system

(5) Nitrogen producer

(6) Inkjet printer

Technical datas

| Model | LZ320 | LZ420 | LZ520 |

| Width of top film | 297mm | 397mm | 497mm |

| Width of bottom film | 322mm | 422mm | 522mm |

| Chamber sizes | 300 x (200-400) mm | 400 x (200-400) mm | 500 x (200-600) mm |

| Maximum forming depth | 80mm | 80mm | 80mm |

| Producing capacity | 1000-11000 pcs/h | 1800-16000 pcs/h | 2400-18000 pcs/h |

| Vacuum | ≤200Pa | ≤200Pa | ≤200Pa |

| Compressed air | ≥0.6MPa | ≥0.6MPa | ≥0.6MPa |

| Pumping rate | 1.1~1.4 m³/min | 1.2~1.6 m³/min | 1.5~2.0 m³/min |

| Cooling water | ≥0.15MPa | ≥0.15MPa | ≥0.15MPa |

| Working speed | 5-9 step/min | 4-8 step/min | 4-6 step/min |

| Work environment | Moisture:≤80% Temperature range:-5°C ~ 35°C | ||

| Power supply | 220V/380V/400V/415V 3phase 50Hz/60Hz | ||

| Power rate | 7 KW | 12 KW | 14 KW |

| Dimensions | 4500mm X 710mm X 1800mm | 7000mm X 900mm X 1900mm | 8000mm X 1000mm X 1900mm |

| Weight | 1300kg | 1800kg | 2100kg |

| Free mould | 2 sets | 2 sets | 2 sets |

Dimensions/sizes/weight are approximate only for reference,actual cases maybe different.

Package samples: