- Overview

- Product Description

- Detailed Photos

- Final biscuits after baking

- Packaging & Shipping

- Certifications

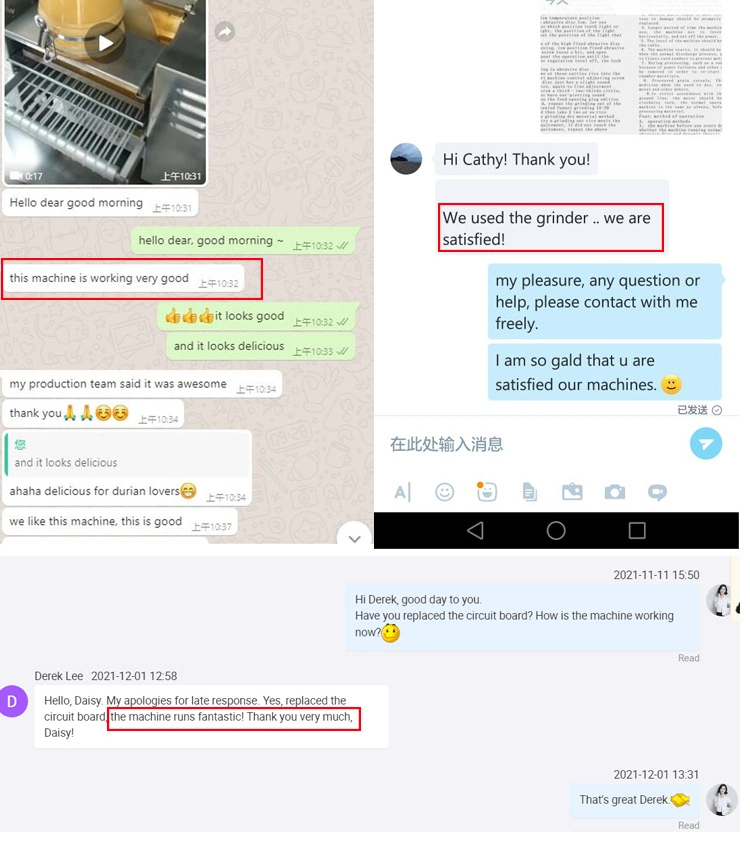

- Feedbacks

Basic Info.

Product Description

Semi-automatic biscuit production line:

Semi-automatic processing flow: kneading - forming - baking - sandwiching - packaging.

1. Adjustable speed ---- The speed of production can be adjusted according to customer requirements, the maximum output can reach 250kg per hour.

2. Stackable baking trays ---- The equipment can automatically place the baking trays, saving you labor costs.

3. Replaceable mold ---- This mechanical flower roller can be customized to produce biscuits with different patterns according to your requirements.

4. Spreader function ---- can be customized according to customer requirements, whether to add ingredients (such as: sesame seeds, etc.) on the biscuits.

5. 32-plate hot air rotary furnace Rotary furnace ---- There are various combustion methods such as electricity, gas, diesel, etc., which are controlled by computer, and the baked products are uniform in color and fragrant.

It can be equipped with a sandwich biscuit machine, and the finished biscuit can be placed in the equipment, and jam, cream, etc. can be injected between the two biscuit.

We also have fully automatic processing lines to choose from.

Push-button control panel, easy to operate.

Set up a safety cover for safety and security.

Double-acting and two-speed rotating at the same time to improve efficiency.

Metal shape, easy to clean.

Large-capacity barrel, a variety of specifications optional.

1. Food grade material mould, sanitary and safe.

2. Biscuit molds can be customized in various shapes, patterns and sizes to make different biscuits.

3. The machine comes with a set of molds.

4. Teflon non-stick tray

Size: 400*600mm

5. The biscuit machine automatically moves the plate. After the plate is placed in the biscuit machine, the machine will automatically put the plate into it.

6. Additional molds of different materials can be equipped according to customer needs.

Hot air rotary oven

1. The grill rotates 360°, and the hot air circulates 360°, so that the temperature and color of the grilled food are uniform. Blast type forced hot air circulation heating, uniform heat transfer.

2. The trolley frame casters are made of high-temperature-resistant plastic, wear-resistant and high-temperature, flexible and do not damage the floor, and there is no noise.

3. The whole machine adopts three-air structure, and the temperature and baking effect are uniform.

4. With spray function. Baked products have good surface moisture retention.

5. The overall furnace temperature is easy to adjust, and the customer can adjust it by himself, which is simple and convenient. The heat preservation is good, and then there is less loss, and the interior can be fully recycled.

1. The whole machine is controlled by three servos, with simple structure, high precision and high speed.

2. Seven-inch touch screen display, easy to operate, clear and clear working status.

3. With formula storage function, no need to repeat settings, save trouble and worry.

4. The bag length can be adjusted automatically, with high precision and accurate sealing and cutting position.

5. There is no standard for stopping position and printing position, which can be set arbitrarily.