Basic Info.

Model NO.

WJ

Material Type

Liquid

Filling Valve Head

Multi-Head

Feed Cylinder Structure

Single-Room Feeding

Dosing Device

Plunger

Filling Principle

Pressure

Packaging Container Lifting Structure

Pneumatic Lifting

Structure

Rotary

Packaging

Bottle

Packaging Material

Plastic

Material

Stainless Steel 304&316

Speed

500bph to 4000bph

Filling Material

Shampoo, Shower Gel and Other Detergent

Suitable Bottle

Pet, PP, PE Bottle From 200ml to 5L

Piston Size

200ml-1L, 1L to 5L

After Sales Service

Online Support, Video Technical Support, etc.

Certificate

CE, TUV, SGS

Market

Worldwide, Especially Africa, Southeast Asia, etc.

Transport Package

Wooden Case

Specification

3.2m*1.8m*2.4m

Trademark

Proman

Origin

China, Jiangsu

HS Code

8422301090

Production Capacity

500machines/Year Filling Machine

Packaging & Delivery

Package Size

200.00cm * 200.00cm * 200.00cm

Package Gross Weight

200.000kg

Product Description

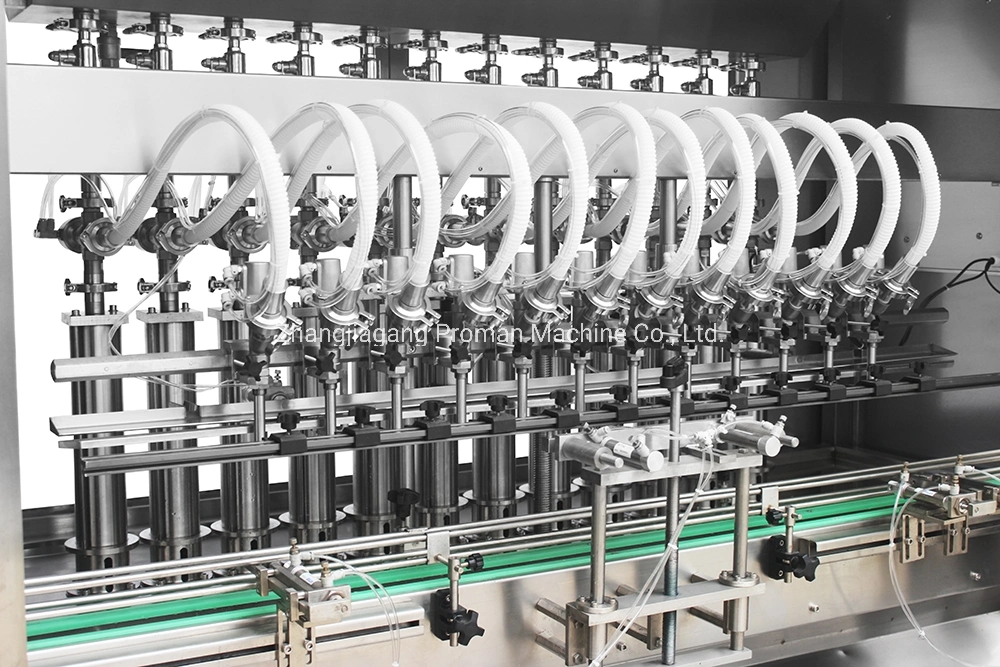

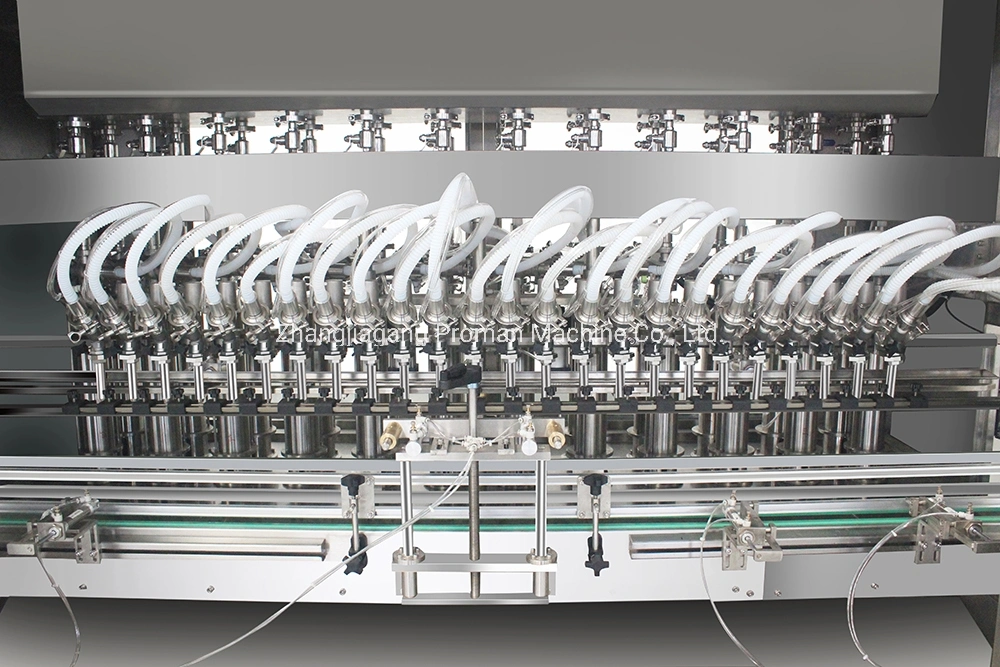

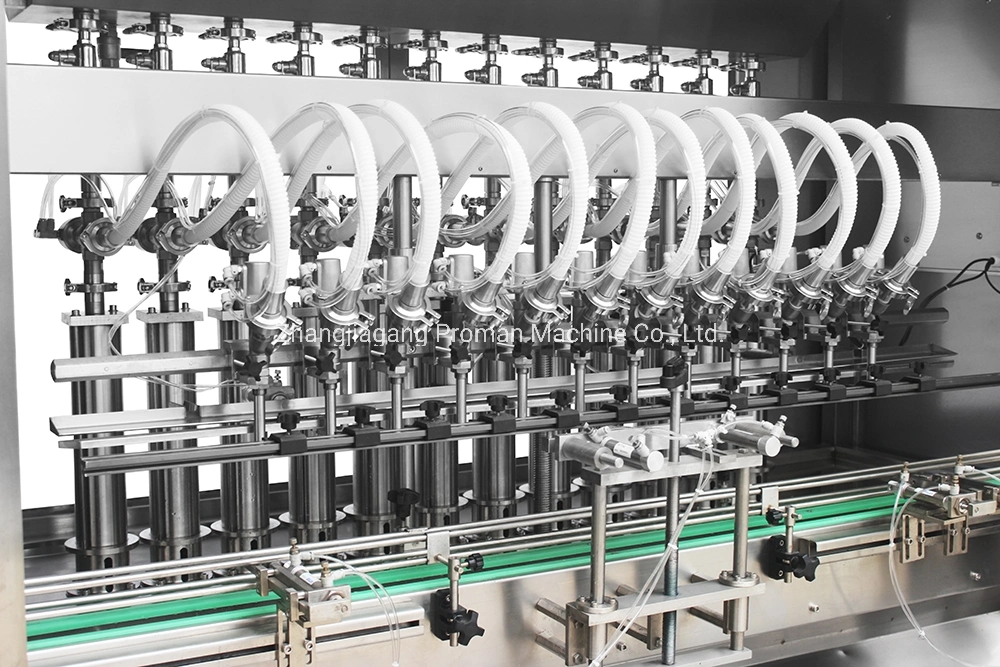

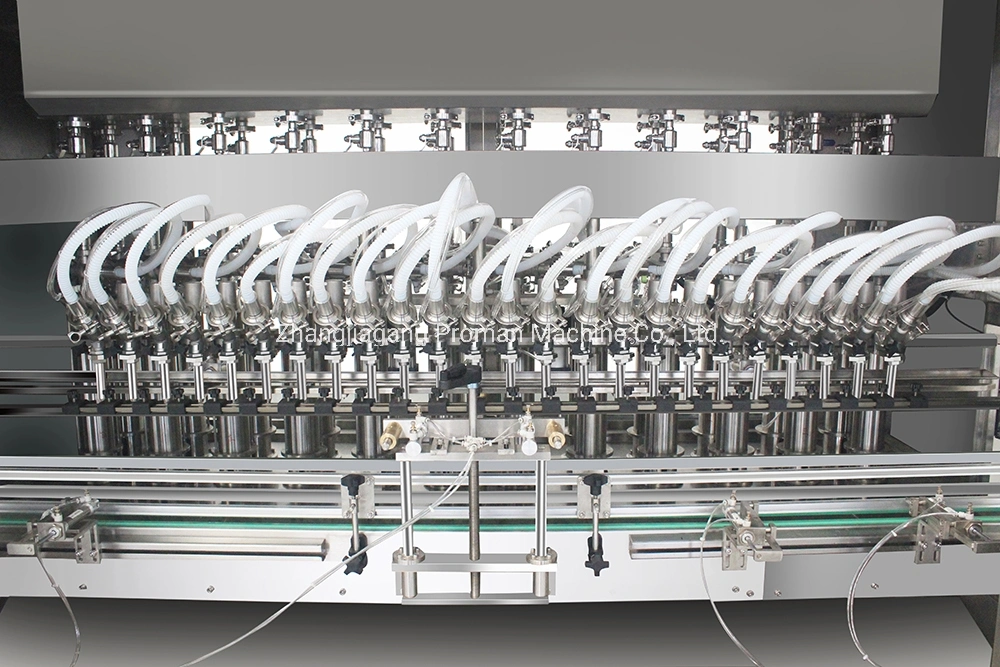

Automatic Plastic Bottle Volumetric Bottling Plant Line Cooking Sunflower Essential Corn Edible Olive Engine Oil Ketchup Honey Sauce Filling Capping Machine

This automatic servo type viscous liquid filling machine is suitable for various viscous and non viscous and corrosive liquid, widely used in plant oil, chemical liquid, daily chemical industry quantitative small packing filling, linear filling, electromechanical integraton control, replacement of species is quite convenient, unique design, superior performance, other in conformity with the concept of international machinery and equipment.

Using the German SIEMENS(SIEMENS) PLC computer, touch screen control, so that it has an intelligent protection function, vacuum drip device to ensure no leakage phenomenon in the production process. Electric control capacity system, frequency conversion control, photoelectric detection using German TUPK products.

Features

Suitable for material: daily chemical viscosity materials.

1.Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position

2. Variable speed filling: in filling process, when close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution

3. Convenient adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment Adopt servo motor to descend

4. Selecting the international famous brand electrical components configuration. Mitsubishi Japan PLC computer, omron photoelectric, Taiwan is produced touch screen, ensure the quality of its outstanding with long-term performance.

Technical parameters

| Model | WJ-01 | WJ-02 | WJ-03 | WJ-04 | WJ-05 | WJ-06 | WJ-07 |

| Filling Head(PC) | 2 | 4 | 6 | 8 | 10 | 12 | 14 |

| Suitable volume(L) | 0.5-6 | 0.5-6 | 0.5-6 | 0.5-6 | 0.5-6 | 0.5-6 | 0.5-6 |

| Productivity (bph) | 350-500 | 700-1000 | 1000-1500 | 1500-2200 | 1800-2500 | 2000-3000 | 3000-4000 |

| Work Pressure (MPa) | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 |

| Power consumption(KW) | 1.0 | 1.1 | 1.5 | 1.5 | 1.5 | 2.0 | 2.0 |

Electrical components of our filling machine

| ITEM | SUPPLIER | Brand | |

| 1 | Touch screen | Taiwan | WEINVEIW |

| 2 | PLC | Japan | Mitsubishi |

| 3 | Photo sensor for bottles | Japan | OPTEX |

| 4 | solenoid valve | Taiwan | SHAKO |

| 5 | Level button | Mexico | JOHNSON CONTROLS |

| 6 | angle seat Valve | Jointed | BURKERT |

| 7 | Diving cylinder | Taiwan | AIRTAC |

| 8 | Power button | France | Schneider |

| 9 | Button | France | Schneider |

| 10 | frequency converter | France | Schneider |

| 11 | Magnetic switch | Taiwan | AIRTAC |

| 12 | oil-water separator | Taiwan | SHAKO |

| 13 | Speed reducer | China | Jiao xing |

| 14 | Relay | Japan | Omron |

| 15 | Servo motor | Japan | Panasonic |

Our service

Customized service

We can design the machines according your requirements(material,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3.We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6.24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7.12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9.Good after-sale service offered, please get back to us if you got any questions.

Our factory was established in the year of 1998, with the long history of accumulated experience in filling machine industry in south Jiangsu. There are many development engineers of filling machine in our company. We devote ourselves to the development, research and production of liquid food and beverage packing and filling industry.

Besides, we have our own designs for the bottles.

Proman Machine cooperated with many customers in recent years, we win the trust of customers from our high-quality products. And we are looking forward to the future cooperation with you if our products can impress you deeply!

FAQ

1.Where is your factory?

1.Where is your factory?

Our Factory is located in Zhangjiagang City, 2 hours drive from Shanghai and 1 hour drive from Wuxi(airplane & high-speed rail). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

2.Do you have any technical supports with your Beverage Filling Machines?

Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

2.Do you have any technical supports with your Beverage Filling Machines?

Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

3.What's your guarantee or the warranty of the quality if we buy your machines?

We offer high quality machines with 1 year warranty and supply life-long technical support.

You're always welcome to visit our company. If you have any interest on our products. Please do not hesitate to contact us.

You're always welcome to visit our company. If you have any interest on our products. Please do not hesitate to contact us.