Basic Info.

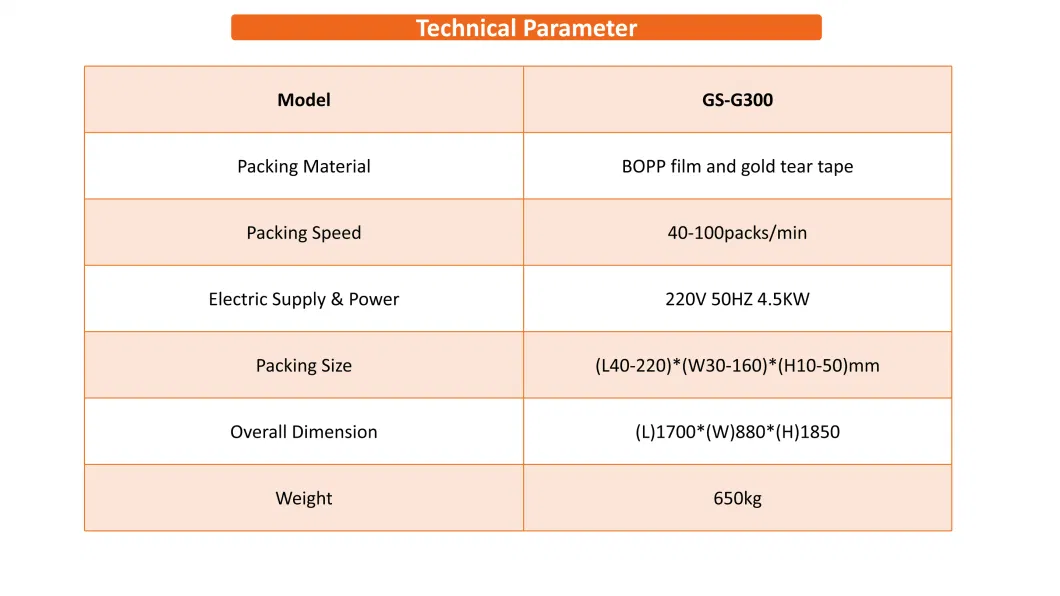

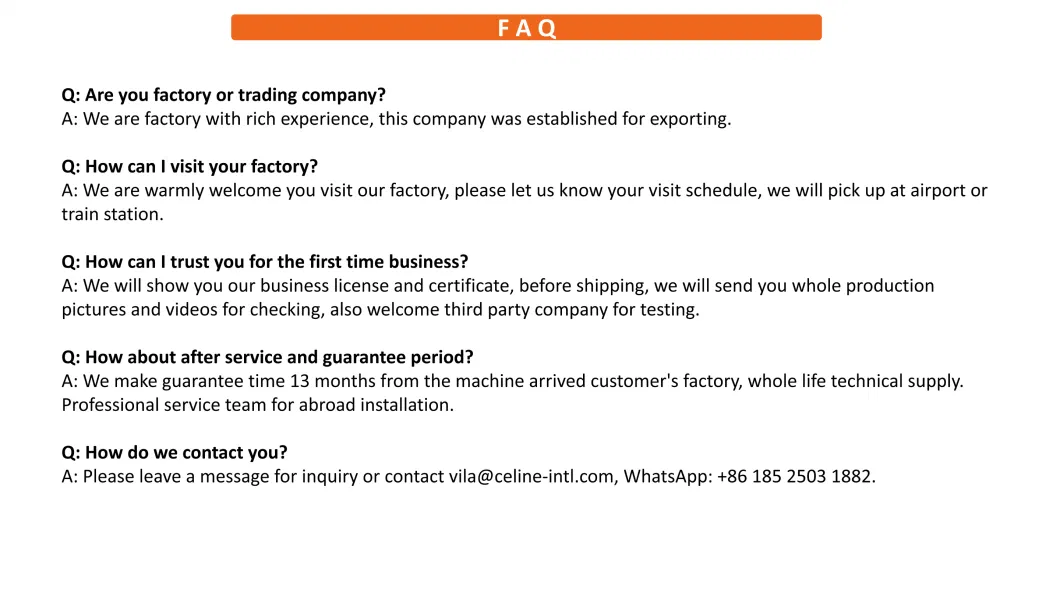

Model NO.

GS-G300

Packaging

Film

Automatic Grade

Automatic

Driven Type

Electric+Pneumatic

Manner of Packing

Four Side Seal Type

Adjust Speed

Frequency Conversion Speed Regulation

Type

BOPP Film

Heating Mode

Stainless Steel Heating

Packaging Material

Film

Packing Speed

40-100packs/Min

Film

BOPP

Max Sealing Size

(L)240*(W)120*(H)60mm

Transport Package

Export Wooden Case

Specification

Stainless Steel

Trademark

CELINE

Origin

China

HS Code

8422303090

Production Capacity

as Actual

Product Description

Automatic Cellophane Wrapping Machine

Application

This machine is suitable for automatic film packaging (with gold tear tape) of single box items in various industries. Adopt imported most advanced PLC programmable controller, with safety door protection and alarm device, to ensure the stability of high-speed operation of the machine, various setting operations can be easily completed on the touch screen. There is no need to adjust the height of the worktables on both sides of the machine when changing the mold, and there is no need to disassemble the discharge chain.

Features

1. This machine is a fully automatic high-speed transparent film packaging equipment. It adopts multi-station turntable alternate packaging method. All wrapping and heat sealing actions are completed by cam transmission. It has the characteristics of fast speed and stable operation.

2. You can pack different size items by replacing the mold. The newly designed multiple patented structure makes it easier and faster to replace the mold.

3. Using the new double-rotating film cutter, the service life is increased by 5 times, and the film cutting is more accurate and smooth.

4. Equipped with a static eliminator, it can effectively eliminate the static electricity absorbed on the packaging film, making the film delivery smoother.

5. The frequency converter is used to adjust the packaging speed. Depending on the packaged items, it can be up to 40~80 bags/min.

6. Equipped with double-sided wrinkle shaping beauty device to make the film packaging more fit and beautiful.

7. With the function of compound self-adhesive laser anti-counterfeit unsealing line, it can really play the role of anti-counterfeiting and anti-moisture.

8. The automatic feeding can be used with the fully automated unmanned production line.

9. This machine adopts safety door protection and alarm device.

10. This machine is equipped with high and low temperature alarm device.

11. This machine is equipped with a boxless shutdown function.

This machine is suitable for automatic film packaging (with gold tear tape) of single box items in various industries. Adopt imported most advanced PLC programmable controller, with safety door protection and alarm device, to ensure the stability of high-speed operation of the machine, various setting operations can be easily completed on the touch screen. There is no need to adjust the height of the worktables on both sides of the machine when changing the mold, and there is no need to disassemble the discharge chain.

Features

1. This machine is a fully automatic high-speed transparent film packaging equipment. It adopts multi-station turntable alternate packaging method. All wrapping and heat sealing actions are completed by cam transmission. It has the characteristics of fast speed and stable operation.

2. You can pack different size items by replacing the mold. The newly designed multiple patented structure makes it easier and faster to replace the mold.

3. Using the new double-rotating film cutter, the service life is increased by 5 times, and the film cutting is more accurate and smooth.

4. Equipped with a static eliminator, it can effectively eliminate the static electricity absorbed on the packaging film, making the film delivery smoother.

5. The frequency converter is used to adjust the packaging speed. Depending on the packaged items, it can be up to 40~80 bags/min.

6. Equipped with double-sided wrinkle shaping beauty device to make the film packaging more fit and beautiful.

7. With the function of compound self-adhesive laser anti-counterfeit unsealing line, it can really play the role of anti-counterfeiting and anti-moisture.

8. The automatic feeding can be used with the fully automated unmanned production line.

9. This machine adopts safety door protection and alarm device.

10. This machine is equipped with high and low temperature alarm device.

11. This machine is equipped with a boxless shutdown function.