Basic Info.

Model NO.

DPP-80

Packaging Type

Aluminum Plastic

Usage

Medical Blister Packaging

Type

Special

Condition

New

Voltage

380V/220V

Main Motor′s Power,

1.5 Kw

Air Pressure, MPa

0.4-0.6

Productivity

35000-230000 Pieces/H

Specification

Weight 1600kg

Origin

Liaoning China

Production Capacity

50 Square Meter/Square Meters Per Month

Product Description

Product Description

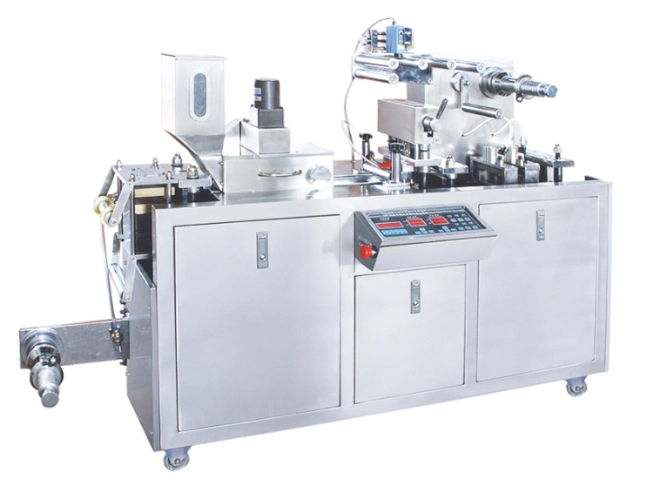

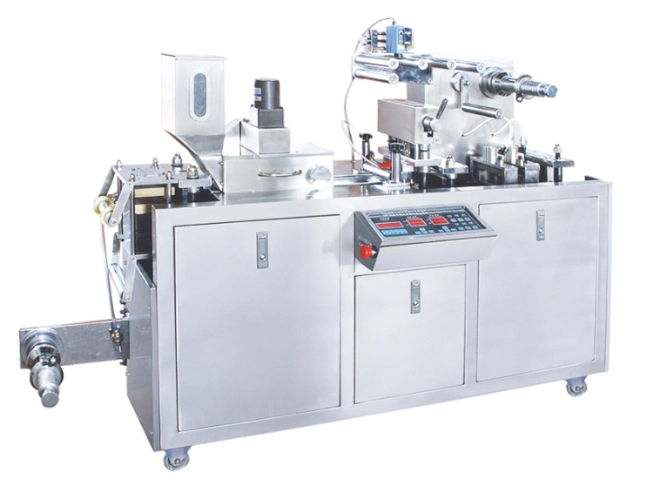

Automatic Blister Packing Machine

Automatic Blister Packing Machine

The Blister packing machine is of flat-plate structure, with pressing, molding, meshes heat-sealing, adjustable travel range, for small size of body and ease of operation. It is applied to Al-Al, Al-PVC, Al-plastic packaging for capsule, table, candy, healthcare, small hardware etc. It is widely used in small pharmacy factory, preparation-room of hospital institute laboratory, mini-motor test workshop. The machine reaches advanced level in China.

Feature

1. Faster Speed-Double heater plate and roller type sealing, .

2. Easier Operation-Adopts top brand PLC controller displayed in Chinese and English, speed control, the length of blister traction adjustable

3. Thermal temperature control and test, over loading protect, PVC and PTP packing material position test, feeder, material position test, failure automatic debug and alarm, automatic protection and stop running.

4. Ensuring accurate registration -Adopts auto photoelectric register device for patterns and words of Al foil driven by step motor, perfect performance.

5. Discharging finished product in right order -automatic collection of bad products, auto rewinding of strap material to ensure easy collection.

6. Auto close and opening of forming plate helps delay the running time after dropping down the heat plate and also makes packing material efficiently used.

7. High Feeding efficiency, reliable and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder)

8. Auto alarm and stop of machine when PVC finds in lack or ruptured, provides much convenience to operator for timely PVC replacement or joint PVC.

9. "GMP" requirements -All parts contact with material including hopper adopt high level stainless steel.

2. Easier Operation-Adopts top brand PLC controller displayed in Chinese and English, speed control, the length of blister traction adjustable

3. Thermal temperature control and test, over loading protect, PVC and PTP packing material position test, feeder, material position test, failure automatic debug and alarm, automatic protection and stop running.

4. Ensuring accurate registration -Adopts auto photoelectric register device for patterns and words of Al foil driven by step motor, perfect performance.

5. Discharging finished product in right order -automatic collection of bad products, auto rewinding of strap material to ensure easy collection.

6. Auto close and opening of forming plate helps delay the running time after dropping down the heat plate and also makes packing material efficiently used.

7. High Feeding efficiency, reliable and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder)

8. Auto alarm and stop of machine when PVC finds in lack or ruptured, provides much convenience to operator for timely PVC replacement or joint PVC.

9. "GMP" requirements -All parts contact with material including hopper adopt high level stainless steel.

Specification

| Product Model | DPP-80 | DPP-140 | DPP-260 |

| Application | Tablet / pill /Capsule | Tablet / pill /Capsule | Tablet / pill /Capsule |

| Cutting Frequency | 10-40Times/min | 15-45 times / min | 25-50 time/min |

| Production Capacity | 2400Plates/h | 4800Plates/h | 6000-12000 plate/h |

| Max. Forming Area And Depth | 80*110*26mm Can Be Customized | 130*110*26mmCan Be Customized | 140*90*20mmCan Be Customized |

| Range Of Standard Stroke | 20-70mm (adjustable) | 20-110mm (adjustable) | 30-120mm (adjustable) |

| Medicinal PVC specification | 0.15-0.5×80mm | 0.15-0.5*140mm | 0.25-0.5×260mm |

| Air Pressure | 0.4-0.6Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Voltage | 380/220V 50Hz | 380/220V 50Hz | 380V/220V 50Hz |

| Power | 3.2kw | 5.2kw | 8.5kw |

| Machine Dimensions | 1600*600*1100mm | 2150*550*1370mm | 4000*760*1620mm |

| Machine Weight | 450kg | 900kg | 1650kg |

Hot-selling Product

Hot-selling Product