- Overview

- Product Description

- Product Parameters

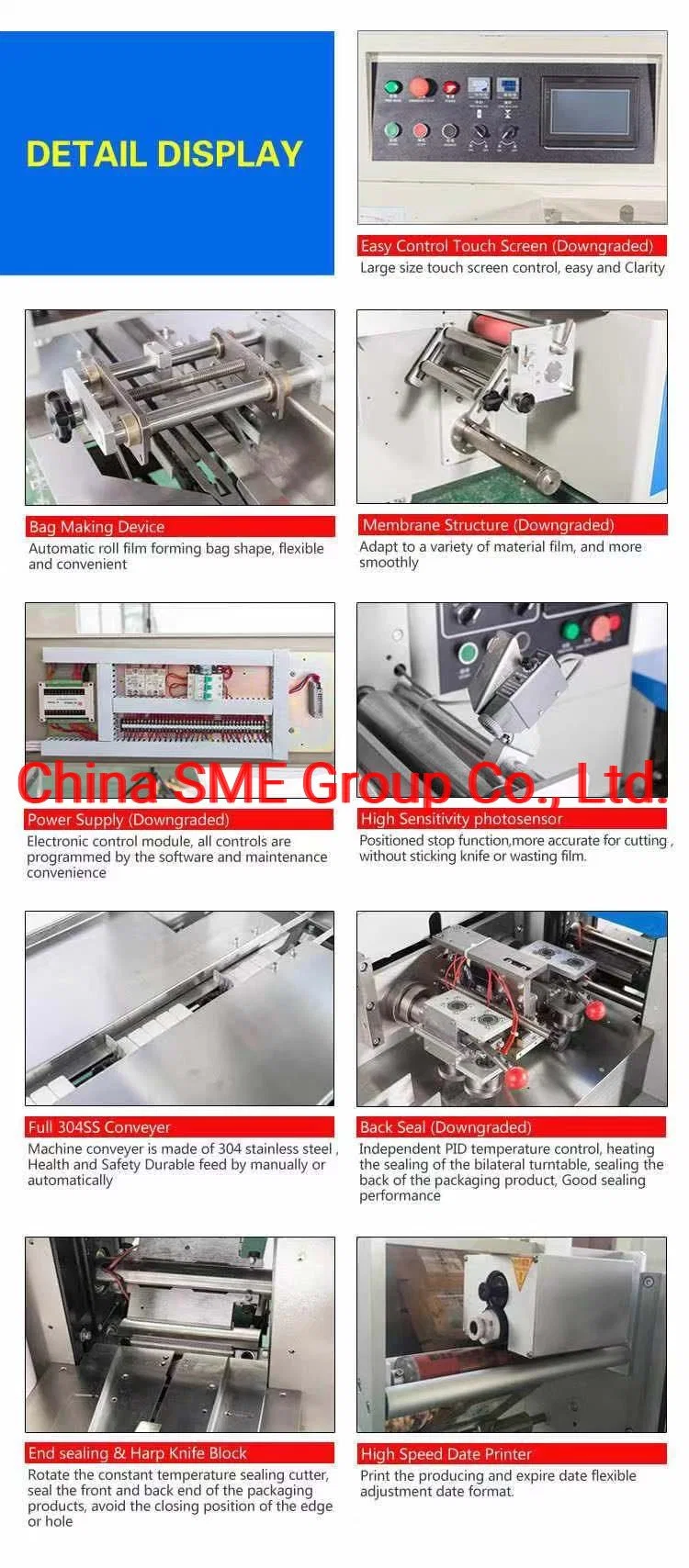

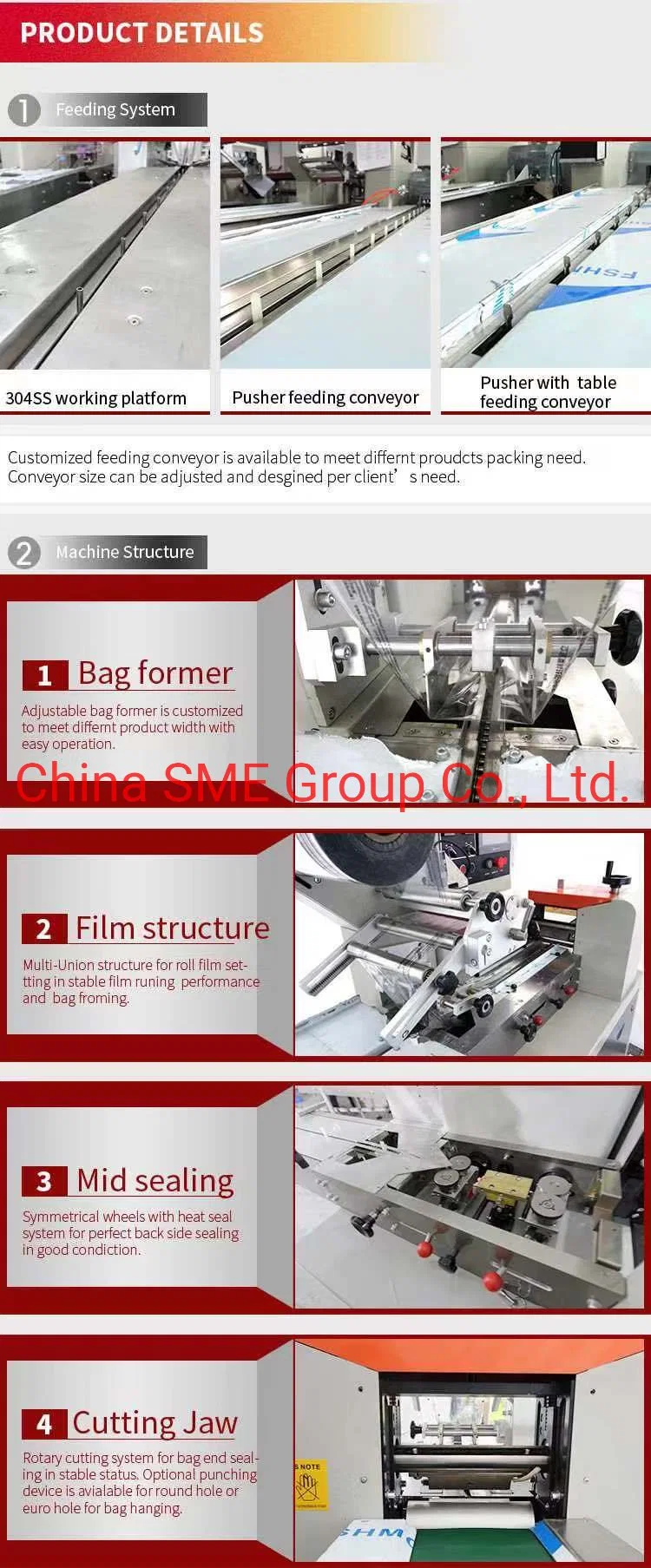

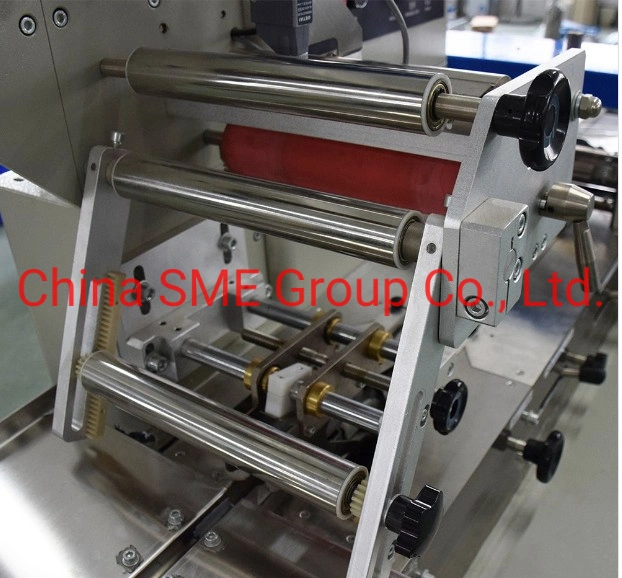

- Detailed Photos

- Packaging & Shipping

- Certifications

- Company Profile

- After Sales Service

- FAQ

Basic Info.

Product Description

Food, Vegetables and Fruits, Hardwares, Hotel Supplies, Stationary, Electric Products, Medical, Daily use Flow Wrap Packaging Machine

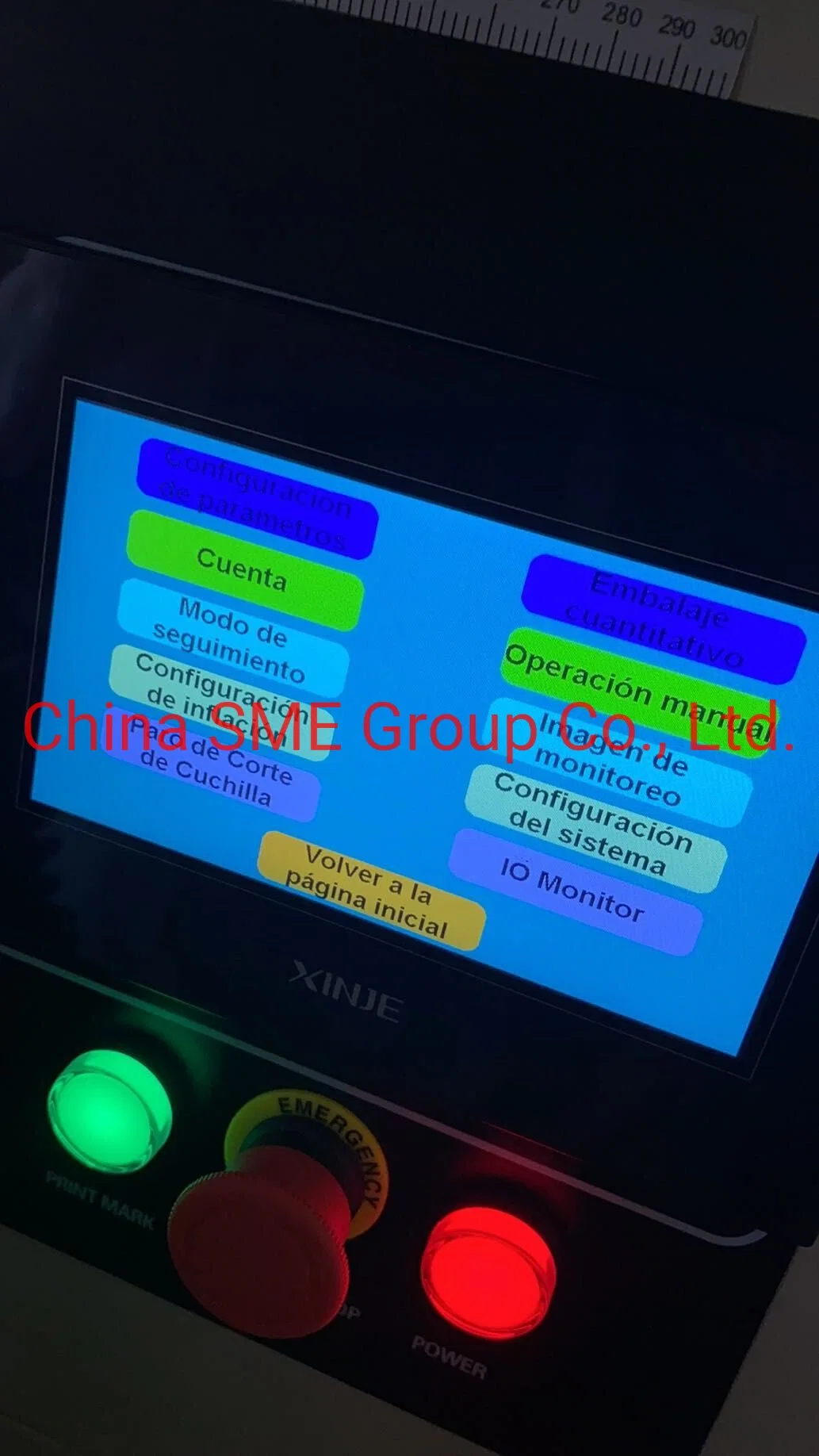

1. Double motor, double Panasonic transducer and PLC controller,flexible bag length setting and cutting,saving time and film.

2. human-machine interface, convenient and quick parameter settings.

3. Self diagnosis failure function, failure displayed clearly.

4. High sensitive optical electric color mark tracking system and digital input cut position, which make the sealing and cutting more accurate.

5. Separated PID control system for temperature, suitable for various packing materials.

6. Stopping the machine in selected position, no sticking on the knife and no waste of the film.

7. Simple driving system, reliable working, convenient maintenance.

8. All controled by program, convenient for function adjusting and upgrading.

Applications of the packaging machine:

Applicable for packing various solid regular objects, such as mooncake, bread, biscuits, candies, snow cakes, custard cakes, chocolates, instant noodles, medicines, commodities, hardwares, carton, trays and etc.

Application:

Food: cake, bread, biscuits, cookies, meat muffin, flaky pastry, moon cake, several sausage in a bag, noodles, beef jerky, egg roll, etc.

Vegetables and Fruits: apples, bananas, lettuce, potatoes, tomatoes, peppers, cucumbers, etc.

Hardwares: hinge, stainless steel pipe, bearings , screw, nuts and washer, etc

Hotel Supplies: soap, disposable comb, tooth paste and brush in one set.

Stationary: pencil, eraser, notebook, paper card, adhensive tape, etc.

Electric Products: battery, usb cable, earphone, user manual and accessories in one set.

Medical: face mask, glove, gauze, capsule, disposable syringe, etc.

Daily use: plastic knife, fork, plate, sponge, scourer, wipes, several straws in a bag, gift, cups, bottles, napkin, baby diaper, etc.

TECHNOLOGICAL PARAMETER

Modle | MZ-250B | MZ-320B | MZ-350X | MZ-400D | MZ-450X | MZ-600B | MZ-700X |

FilmWidth | Max.250mm | Max.320mm | Max.350mm | Max.400mm | Max.450mm | Max.600mm | Max.700mm |

Bag Length | 65-190mm | 65-190mm | 65-190mm | 130-230mm | 120-450mm | 120-450mm | 120-450mm |

Bag Width | 30-110mm | 30-150mm | 50-160mm | 50-180mm | 50-200mm | 80-270mm | 100-330mm |

Product Height | Max.40mm | Max.40mm | Max.45mm | Max.65mm | Max.80mm | Max.80mm | Max.80mm |

Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

Packing Speed | 40-230 bags/min | 40-230 bags/min | 40-230 bags/min | 40-230 bags/min | 30-150 bags/min | 20-80 bags/min | 20-80 bags/min |

Power Specification | 220V,50/60 Hz,2.4KW | 220V,50/60 Hz,2.4KW | 220V,50/60 Hz,2.4KW | 220V,50/60 Hz,2.8KW | 220V,50/60 Hz,2.8KW | 220V,50/60 Hz,3.2KW | 220V,50/60 Hz,2.4KW |

Machine Size | 3770*670* 1450mm | 3770*670* 1450mm | 3770*670* 1450mm | 4020*800* 1450mm | 4020*800* 1450mm | 4380*970* 1500mm | 3770*670* 1450mm |

Machine Weight | 500KG | 500KG | 500KG | 600KG | 700KG | 850KG | 900KG |

Optional Accessories:

- Air Filling Device

- Date Coder

- Angle Folding Device

- Hole Punching Device

- Magazine Filling Machine

- Alcohol Spraying Device

- Deoxidizer Chute Device

- Nitrogen Flushing Device

- Notch and Auto Labeling Machine

- Alternative Sealing Machine

- Cutting Device

Function: It can print Manufacture date,Expiration date and Batch number on the bag

6. Main Electrical Brand

| 1.PLC Panasonic from Japan | |

| 2.Inverter Panasonic from Japan | |

| 3.Close to Switch Omron from Japan | |

| 4.Switch Button Sch-neider from German | |

| 5.Terminals Wade Miller from German | |

| 6.Display Screen WeiLun from TaiWan | |

| 7.Motor Jiangcheng from Guangdong | |

| 8.Photocell Yetai from Taiyan | |

| 9.Temperature Control List Omron from Japan | |

| 10.Pushbutton Switch Sch-neider from German | |

| 11.Power Ming Wei from Taiwan | |

| 12.Solid State Relay Sch-neider from German | |

| 13.Intermediate Relay Omron from Japan | |

| 14.Two Wire Switch Sch-neider from German | |

Machine Details:

More detaild picture

8.Packing Materials:

Heat-sealable laminated film: such as OPP,Aluminized,POPP& other special sealable packing film

9. Spart PartsS

1. Three pushers

2. A Mid-seal belt

3. A solid-state relay

4. Two heating tubes

5. One set tools

6. User manuels

7.Four foot cups

8.One set power cable.

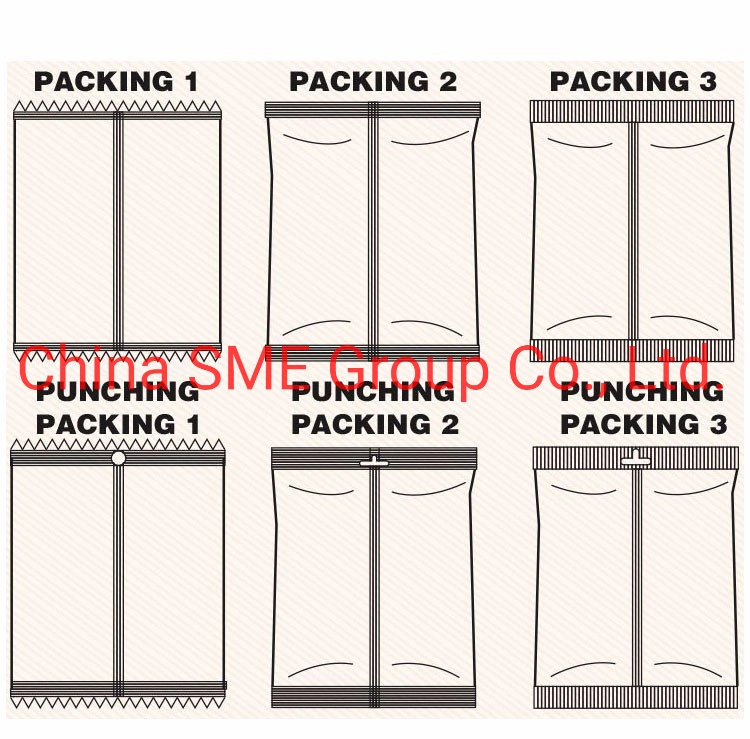

10. Bag Type

11. Packing Method

Exporting Wooden Cases: 1 machine with 2 wooden boxes

12.Our Client :

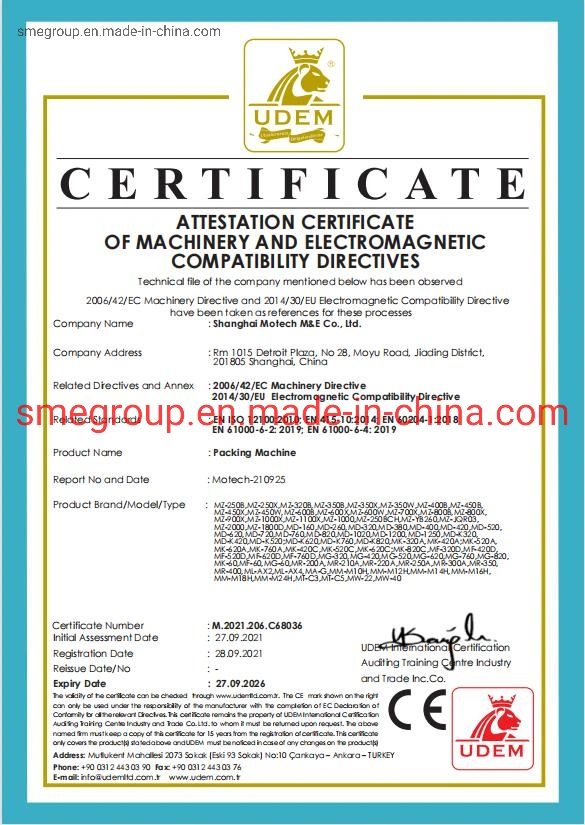

Our Certification:

About US:

SME is a leading manufacturer in the field of front-of-line packaging devices since 2008. In the past 10 years, MOTECH has targeted on the technology development, precise manufacturing, professional marketing, satisfied technical support and OEM solutions. We offer Flow Packing Machine;Vertical Packing Machine;Metal Detector;Weight Checker and Weighter to fit the needs of different industries.

Due to continuous efforts in the field of end-of-line packaging devices, MOTECH Machinery was honored to obtain CE certificate and ISO 9001 certificate showed our emphasis on safety ,quality and has a successful sale in Asia, American, Africa and so on. MOTECH looks forward to establishing a long-term and mutual beneficial partnership with more agents or distributors all over the world. Moreover, We provide the OEM solution based on strict quality control for famous companies in Japan, USA etc.

In the future, MOTECH Machinery will keep to provide customers:

-Quality machines

-Competitive price

-Satisfied service

Our Team:

Pre-sales service:

1.We provide presales service in various forms, making investment budge, manufacturing, planning, so that customers can make a reasonable plan with less cost.

2.We will fist check customer's goods and goods size, then we will recommend suitable wrapping machine to 100% suitable.

3.We will recommend and offer machine according to customer's use and purchase budget.

In-sale service:

1.We will supply each manufacturing step photo for customer checking on time.

2.We will prepare packing and shipment according to customer's needing in advance.

3.Testing the machine and making video for customer's checking.

After-sale service:

1.We will guarantee the machine quality for 1 years.

2.We provide free training and answer customer's question on technology in time.

1. What about your pillow packing machine quality?

Our factory has 10 years experience in mechanical processing; all our machines already get ISO9001, SGS

certificate, CE certificate; already exported into many countries and areas; already got customer's good reputation.

2. What about your pillow packing machine price?

Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied price!

3.Can you send me the video to show how the pillow packing machine work?

Certainly, we have made video of every machine and uploaded them by our chain address.Pls. contact with us, we will send you machine video.

4.What about your installation service and sales service for pillow packing machine?

1>Guarantee is two year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2>We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3>It is free to train your worker in our factory or in your side or by video.

https://smegroup.en.made-in-china.com/contact-info.html