- Overview

- Application

- Product Parameters

- Company Profile

Basic Info.

Application

Cleaning, Detergent, Cosmetics, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning

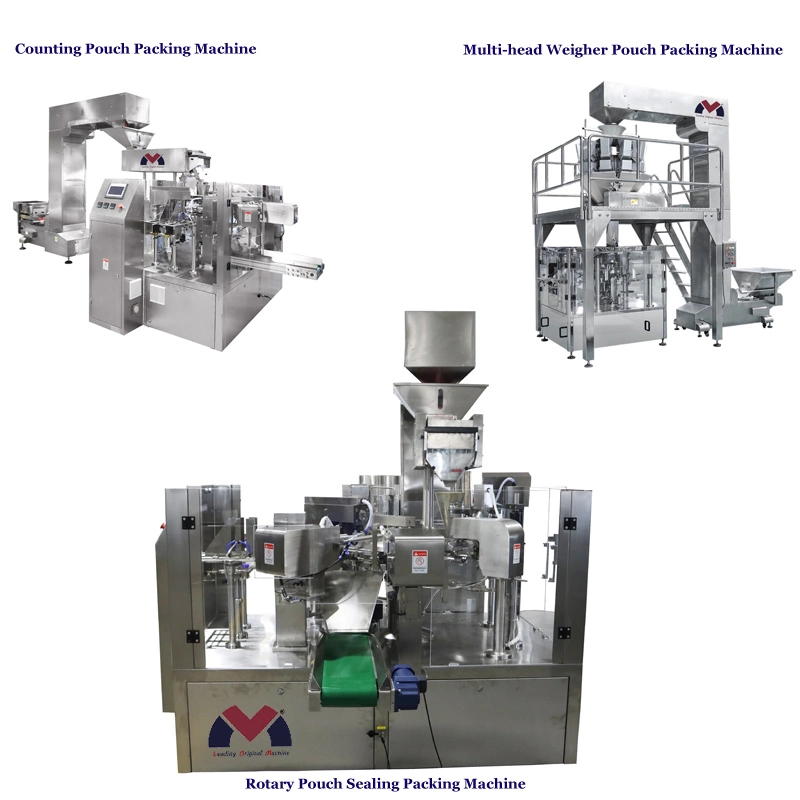

Type

Filling and Sealing Machine

Forming Species

Bag Moulding

Forming Function

Filling, Seal

Driven Type

Pneumatic

Material Type

Soild,Liquid

Packaging

Pouch Bag,Premade Bag

Packaging Material

Plastic Bag,Kraft Paper Bag,Aluminum Foil Bag

Transport Package

Standard Export Wood Case

Specification

2500x1460x1250mm

Trademark

LOM

Origin

China

Production Capacity

50 Pieces/Month

Product Description

| Machine Name | Automatic Rotary Doy Pack Pouch Packing Machine | |||

| Packaging Material | Gummy,candy,capsule,pill,jewelry,screw,powder,liquid,paste | |||

| Max Speed | 30-60 bags/min | |||

| Width of bag | 100-200mm | |||

| Length of bag | 100-400mm | |||

| Filling range | 10-2000g | |||

| Type of sealing | Straight + Reticulated | |||

| Voltage and Power | 380V,50Hz,9.8KW | |||

| Extra connecting machines | Counting machine,multihead weigher,shrink wrapping machine,vacuum pack,labeling machine,horizontal packaging line or vertical packaging line | |||

Main Feature:

1.New type: one-piece simplified single shaft cam structure with inner wheel groove at the main part

1) The new machine adopts the Japanese machine structure. All transmissions are sent out by one shaft. The transmission is simple and direct, with little wear and convenient maintenance.

2) Thicken the cam, make a groove wheel on the surface, and fix the transmission swing arm in the groove wheel for operation. The running track of the transmission swing arm is fixed, greatly reducing the impact wear, doubling the machine life, greatly reducing the noise, and ensuring stable machine operation

2.The independent electrical box shall be arranged scientifically and reasonably, free of any disordered pipelines, and sealed without redundant openings to prevent foreign matters from entering.

3. The use of No. 40 baked steel and mixed wear-resistant materials improves the wear resistance of gears from the tedious process of oiling every day to oiling every month, greatly reducing the workload of workers and making operation and maintenance more convenient.

4.The whole machine is required by European export standards, most of which are imported from Germany and controlled by Siemens PLC

FAQ

1. Why choose us?

LOM Machine have more than 15 years experience in machine industry, having export machines to US,Europe and other more than 30 countries and received lots of good comments from customers.

2.How to order?

For the customized machine, you should let me know your voltages, filling volume, material, style etc.

3.Does it suit for my production?

We can create machine by your customized requirements and based on your samples.

4.Delivery time?

Usually 10-35 days production after samples arrival.

5. How do you control the quality?

GMP(Good Manufacturing Practice)dust-free manufacturing workshop, and professional QC test 3 times before packing.

6. Warranty?

Lifelong service and warranty 1 year for quality.

7. How will you support for installation and after-service?

FAQ

1. Why choose us?

LOM Machine have more than 15 years experience in machine industry, having export machines to US,Europe and other more than 30 countries and received lots of good comments from customers.

2.How to order?

For the customized machine, you should let me know your voltages, filling volume, material, style etc.

3.Does it suit for my production?

We can create machine by your customized requirements and based on your samples.

4.Delivery time?

Usually 10-35 days production after samples arrival.

5. How do you control the quality?

GMP(Good Manufacturing Practice)dust-free manufacturing workshop, and professional QC test 3 times before packing.

6. Warranty?

Lifelong service and warranty 1 year for quality.

7. How will you support for installation and after-service?

All machines are as complete as possible when arrive at your workshop,we will providing manual booklet and our experienced engineers are available online 24/7, installation videos and video calls are anytime for you.