- Overview

- Product Parameters

- Product Display

- Company Profile

- Certificate

- Exhibition

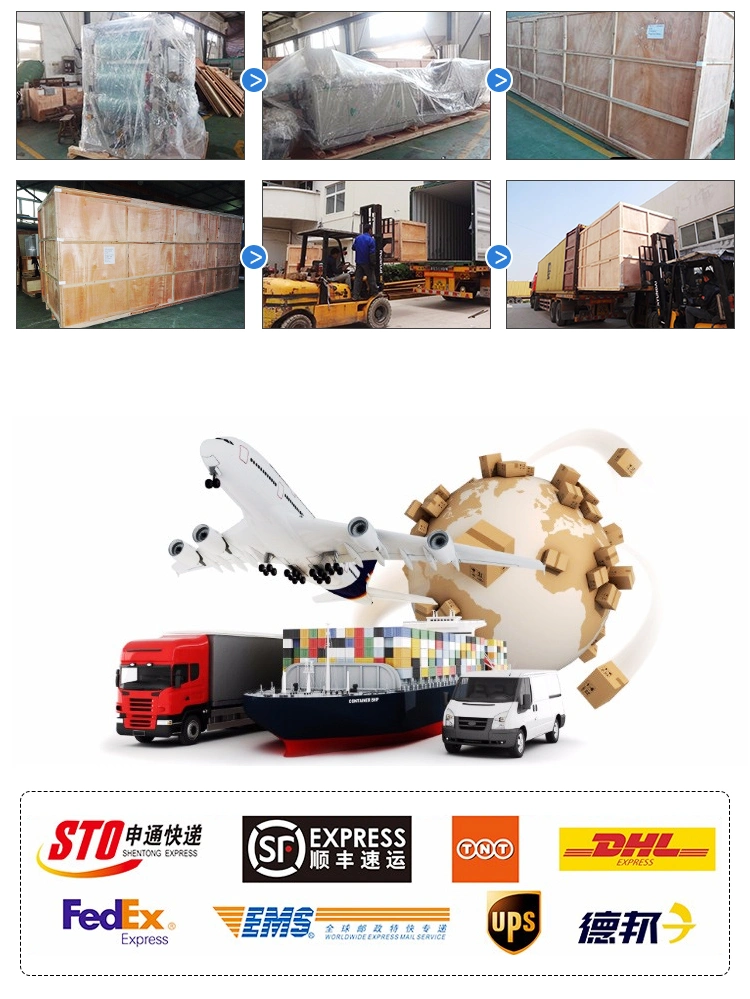

- Transport Packaging

- FAQ

Basic Info.

Product Description

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 100mm |

| Sheet thickness | 0.2-2.0mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 100Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L9700*W4600*H2700mm |

| Weight | About 9.0T |

Application:

Application:

TTF series full-automatic thermoforming machine is our latest developed core product. The machine

combines forming, cutting, and stacking into process. widely used and suitable for most of the customer

requested, it can produce plastic trays, containers, boxes, lids, etc. The machine is completely driven

by servo motor. stable operation, low noise, high efficiency, high quality. SUMMARY OF MACHINE

SUMMARY OF MACHINE

- Every station is driven by the eccentric crank linkage structure.

- Feeding and heating part have optoelectronic switch in order to prevent error operating from production process.

- The toothed chain made of 65#Mn, helping convey sheet. Aluminum rails with water cooling, save water.

- The machine adopts PID temperature system, it shows high precision, and temperature control tolerance <1ºC.

- Each servo motor has overload protection for machine's overworking.

- Low barycenter and height of finished products as well as steady running ensures easy operation and friendly viewing.

There is an alarm function of the sliding doors.

Q1: Are you a factory or trading company?

A1: We are a factory, and we export our machines to more than 80 countries since 2001.

Q2: How long is the warranty period?

A2: We have a professional QC department in charge of products' quality.

Q3: How long is the warranty period?

A3: 13months calculated from the date of shipment from our factory.During warranty period, except the artificial factor, the spares are free to maintenance, beyond the warranty time, the buyer needs to pay the spare charge and shipping cost.

Q4: How to install the machine?

A4: We will send technician to your factory to install the machine, and teach your workers to use it. You pay all related costs, including visa charge, double-way tickets, hotel, meals, and technician salary.