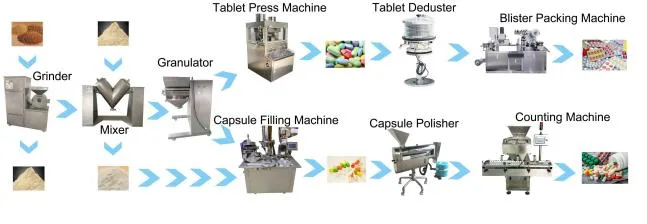

- Overview

- Product Description

- Product Parameters

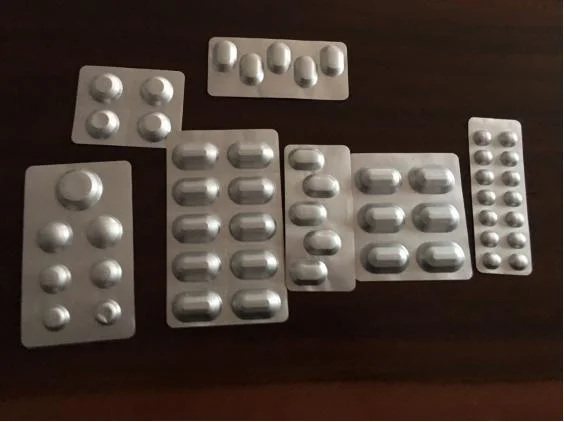

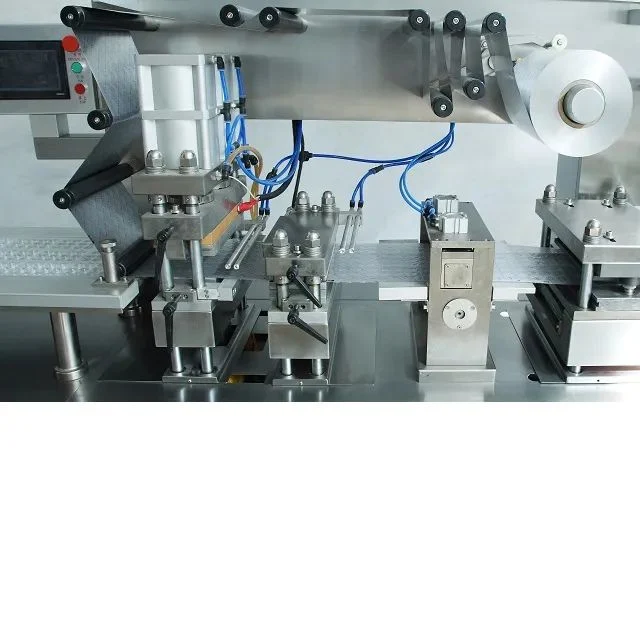

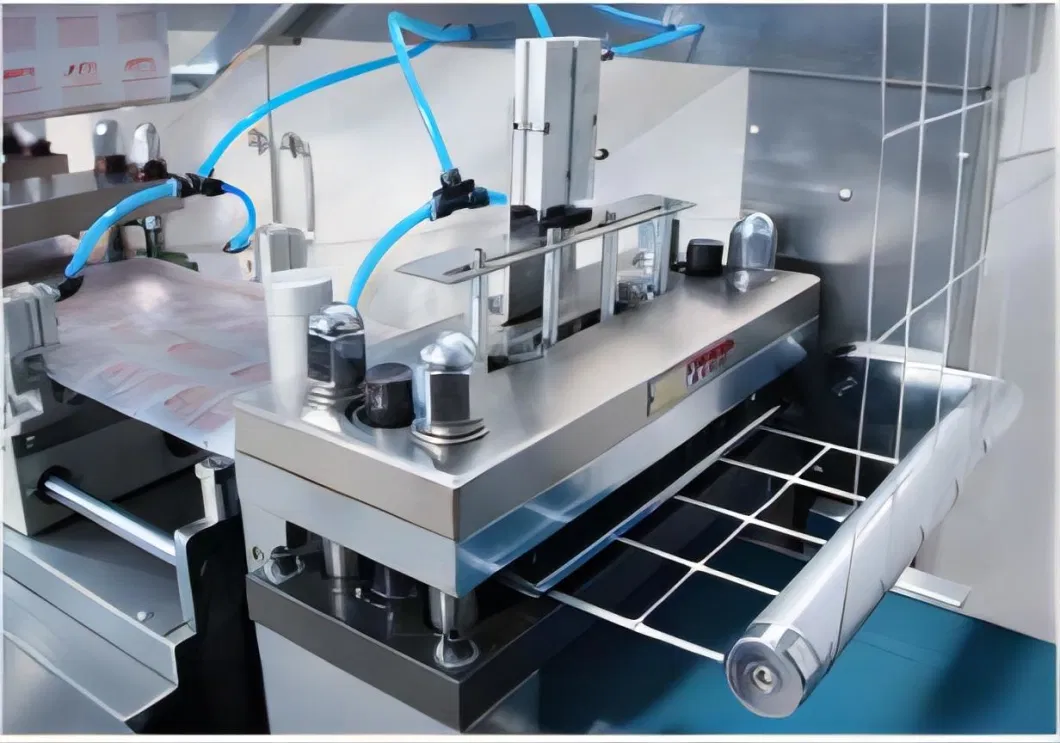

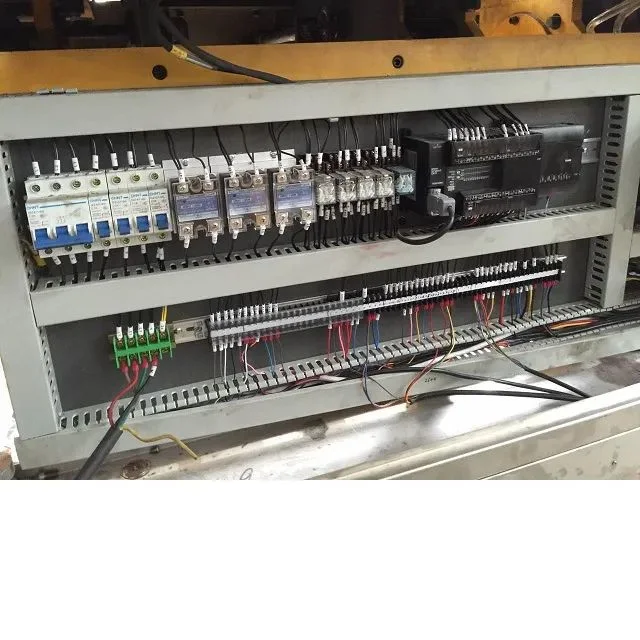

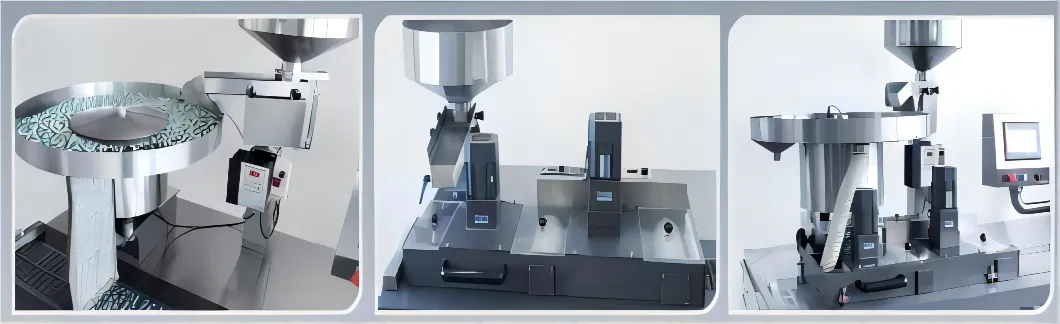

- Detailed Photos

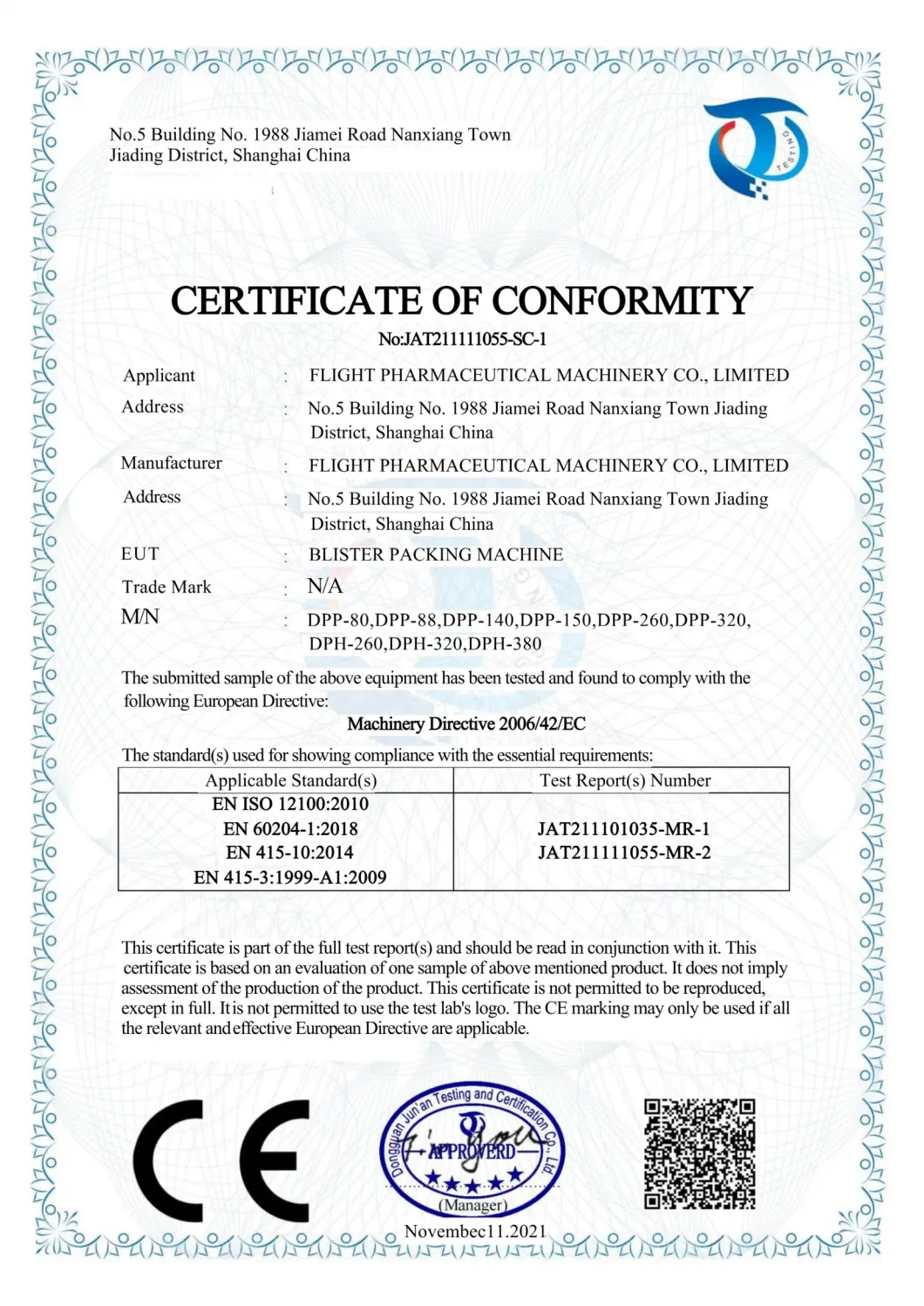

- Certifications

- Packaging & Shipping

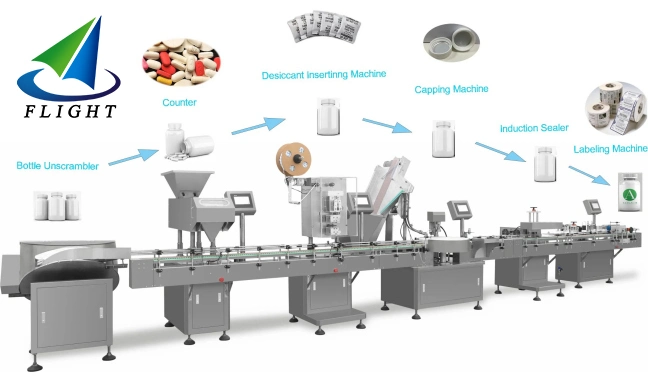

- Company Profile

- After Sales Service

- FAQ

Basic Info.

Packaging & Delivery

Product Description

Fully automated large flat blister packaging machine DPP-260

Has advantage as compact structure, full function, gear wheel working, and accurate

Synchronization, stable cooperation, easy to replace the mould, low cost and needn't to equip

Auxiliary unit. Turn on power and connect it with cooling water, you can produce in a large scale.

The machine is widely used in the vocation of medicine, foodstuff, electron, hardware for

AL/PVC blister packing of various nubby objects, such as capsule, tablet, pill and electronic part.

This machine adopts micro-computer PLC, frequency converter, touch panel operation, high automation.

| Cutting Time (t/min) | Al-AL 6-25 Al-plastic 6-50 Paper-plastic 6-50 |

| Max. Production Capacity(pcs/h) | Al-Al ≤110000 Al-plastic ≤230000 |

| Max. Forming Area And Depth (mm) | Al-Al 240×150×15 Al-plastic 240×150×26 |

| Travel Range (mm) | 40-160 (Can be manufactured as user's requirements) |

| Standard Plate (mm) | 80×57 (Can be manufactured as user's requirements) |

| Air Pressure (Mpa) | 0.4-0.6 |

| Air Supply | ≥0.3m3/min |

| Total Power | 380V/220V 50Hz 6.2kw |

| Main Motor Power (KW) | 1.5 |

| Forming Aluminum (mm) | 0.10-0.15×250 |

| PVC Sheet (mm) | 0.15-0.5×250 |

| PTP Aluminum Foil (mm) | 0.02-0.035×250 |

| Dialysis Paper (mm) | 50-100g×250 |

| Mould Cooling | Tap Water Or Circulating Water |

| Overall Dimension (mm) | 3000×730×1600(L×W×H) |

| Weight (kg) | 1600 |

Configuration list

| No. | Descriptions & Specifications | Unit | Qty. | Remarks |

| 1 | DPP-260 Auto Blister Packing Machine | Set | 1 | |

| 2 | Steel Letters 0-9 | pcs | 100 | |

| 3 | Steel Brush | pcs | 1 | |

| 4 | Pliers, | pcs | Each one | |

| 5 | Screwdrivers "Flat" "Cross" | pcs | Each one | |

| 6 | 4' 5' 6' 8' 10' 12' Socket Head Spanners | pcs | Each one | |

| 7 | 8'12' Spanners | pcs | Each one | |

| 8 | Pressure Oil Pot | pcs | 1 | |

| 9 | Oil Stone | pcs | 1 | |

| 10 | Forming Sealing Ring | M | 3 | |

| 11 | Rolling Wheel | pcs | 1 | |

| Technical Documents | ||||

| 1 | Operating Instructions of DPP-260 | pcs | 1 | |

| 2 | Quality Certificate | pcs | 1 | |

| 3 | Operating Instructions of Temp. Controller | pcs | 1 | |

| 4 | Operating Instructions of Frequency Inverter | pcs | 1 | |

For different products, we have different feeders that can be customized according to customer requirements, with good feeding effect and high production accuracy

The machine adopts three production tracks, achieving true industrial production in terms of output, which can meet the standards of the production company. It also has positioning pins on the installation of the mold, which can better replace the mold. For the pattern machine, it has cursor alignment, ensuring that the pattern of each blister is in the same position

Vibration feeder:

The machine can choose to use a vibration feeder, which has good effects on capsules and tablets, avoiding damage to drugs during the feeding process and avoiding the impact of dust received during the production process

We have rich export experience and enjoy global customers

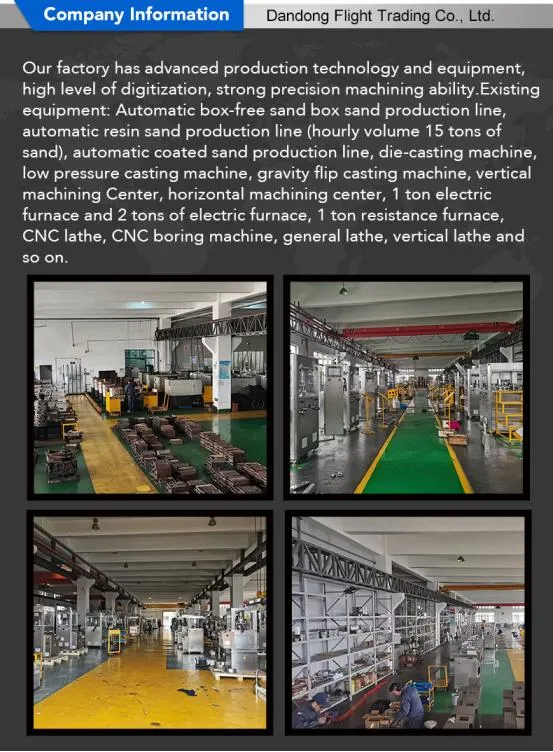

Dandong Flight Pharmaceutical Machinery Co., Ltd. is located in Dandong Donggang City, a top 100 County in China. It is a member of China Pharmaceutical Equipment Association and has passed ISO9001:2000 certification. The head office Shanghai Flight Pharmaceutical Machinery Co., Ltd., founded in 1999, is an earlier manufacturer of pharmaceutical production lines in China.

Dandong Flight Pharmaceutical Machinery Co., Ltd. is located in Dandong Donggang City, a top 100 County in China. It is a member of China Pharmaceutical Equipment Association and has passed ISO9001:2000 certification. The head office Shanghai Flight Pharmaceutical Machinery Co., Ltd., founded in 1999, is an earlier manufacturer of pharmaceutical production lines in China.

The company is based on the enterprise concept of "integrity and friendship", establishes its business in good faith and wins the world with courtesy. Achieve higher quality, better service and lower price. We have advanced technology to produce first-class pharmaceutical equipment. It mainly focuses on the production of tablet press, filling line, packaging line and various small and medium-sized equipment. Over the years, we have continuously improved and innovated, reached cooperation with nearly 100 manufacturers and customers at home and abroad, and welcome customers at home and abroad to exchange technology with us.

We provide free technical guidance to them, so as to make common progress with the times! With first-class quality, first-class service, first-class reputation and first-class products, the company creates high-quality products in China and builds a bridge of friendship. The company sincerely hopes to work with friends in the industry to improve the technical level of domestic pharmaceutical technology.

Our company's technology

Our workshops were modernized, and equipped with high precision processing facilities such as vertical and horizontal machining centers, digital CNC gantry milling machine and NC lathes, etc.

1.FCA Shanghai T/T payment

2.Payment Terms: 50%TT before production +50%TT before delivery

3.Lead Time: 3-21 working days after receipt of prepayment and samples

4. Package: in wooden box, confirm to international transportation standard.

5.Technical Standard: Confirm to GMP and relative international regulation.

6.Warranty: The supplier provides 12 months free warranty since the date that the product

was adjusted and qualified, and there is no artificial destruction in this period. Supplier

provides lifetime service support.

7.Installation, Adjustment and Training

The seller provides instrument and video about how to install, adjust and use the machine as

soon as the machine is ready. The seller provides on-time service when user have use problem.

The seller can dispatch one engineer to the buyer's factory for installation and commissioning

and training, the buyer should be responsible for the room and board and the go-back air tickets and visa fee.

Q: What about your pharmaceutical machine quality?

A: Our factory has more than 10 years experience in mechanical processing; all our machines already get IS09001, SGS certificate, CE certificate; already exported into many countries and areas; already got customer's good reputation.

Q: What about your pharmaceutical machine price?

A: Anytime we will make quality as factory life, no matter price is good or not for us. Quality is first, on the top quality basis, Sure you will get reasonable and satisfied pricel.

Q: How can you ensure the machine's quality after we put the order?

A: Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

Q: What about your installation service and sales service for pharmaceutical machine?

A: 1>Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

2>We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

3>It is free to train your worker in our factory or in your side or by video.