- Overview

- Product Description

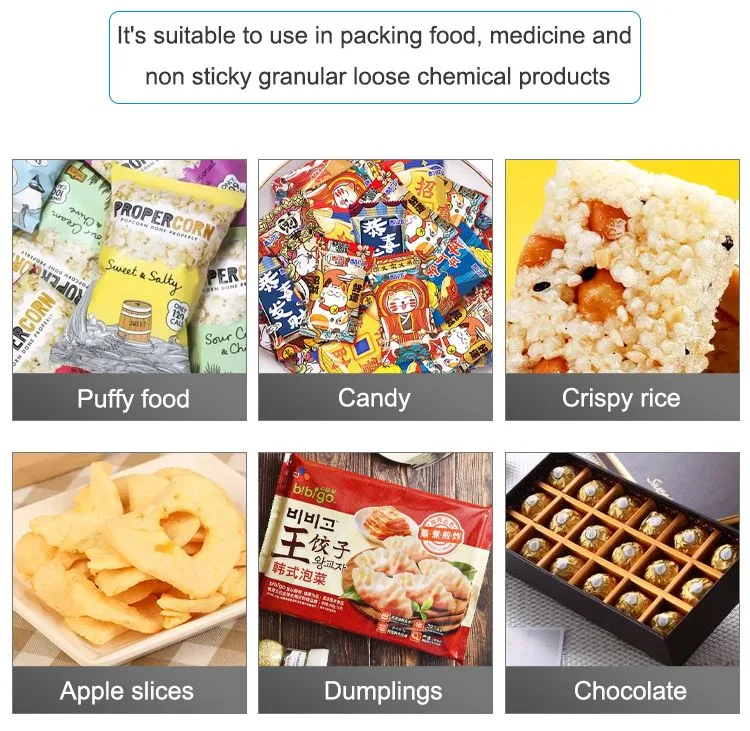

- Recommended Products

- Our Advantages

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

Vertical puffing packaging machine

Forming Function

Forming, Filling, Seal

Driven Type

Electric

Material Type

Solid

Packaging

Bag

Packaging Material

Film

Bag Length

Customized

Power

220V

Capactity

70bag/Minute

Presicion

0.5-2g

Quality

High Quality

Transport Package

Wooden Case

Specification

customized

Trademark

Dejiu

Origin

Shandong

HS Code

8422303090

Production Capacity

100/Month

Product Description

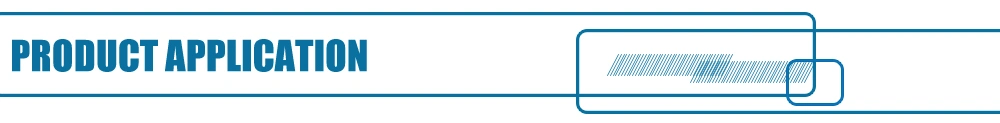

Apply for the packaging of medical supplies, food, hardware and other particle in bulk such as electuary, spices,sugar, coffee,seeds and monosodium glutamate .

Apply for the packaging of medical supplies, food, hardware and other particle in bulk such as electuary, spices,sugar, coffee,seeds and monosodium glutamate . 1,Stainless steel surrounds the part where contact to the material. The machine is accordant with the European CE standard.

2,The computer controller is the first patented product in China, an advanced frequency converter, and supports multi-language control.

3,Rolled disc cup adjusting device can adjust packaging capacity during running the machine, reduce the lostof material and improve productivity.

4,Bag-making equipment can be changed according to specific requirement of customers and products so as to adjust the amount of packaging.

5, Multi-language touch screen can switch various languages at the same time, and when there is a problem with the machine, it will automatically alarm, pause the operation and show where the machine is in the problem.

6, Screw metering, Kitech exclusive patented technology device, using a new straight screw metering weighing, when the packaging weight is not accurate will automatically adjust to reach the preset weight, no manual operation to adjust, saving time and cost.

7, Double Scale Weighing Device, Kitech's exclusive patented technology device,Secondary weighing and testing of the finished packaging products, when the packaging weight is not accurate, it will automatically reject the unqualified products and feed back to the measuring cup metering device system for automatic adjustment of the entire weight, which will increase the qualified rate products to 100%.

8,Servo control system is used on machine weighing device, film pulling device, bag making and sealing. When there is a problem in one part, the machine will automatically stop running and alarm to remind the operator to check, therefore, one person can operate 15 machines at the same time to save cost.