Basic Info.

Model NO.

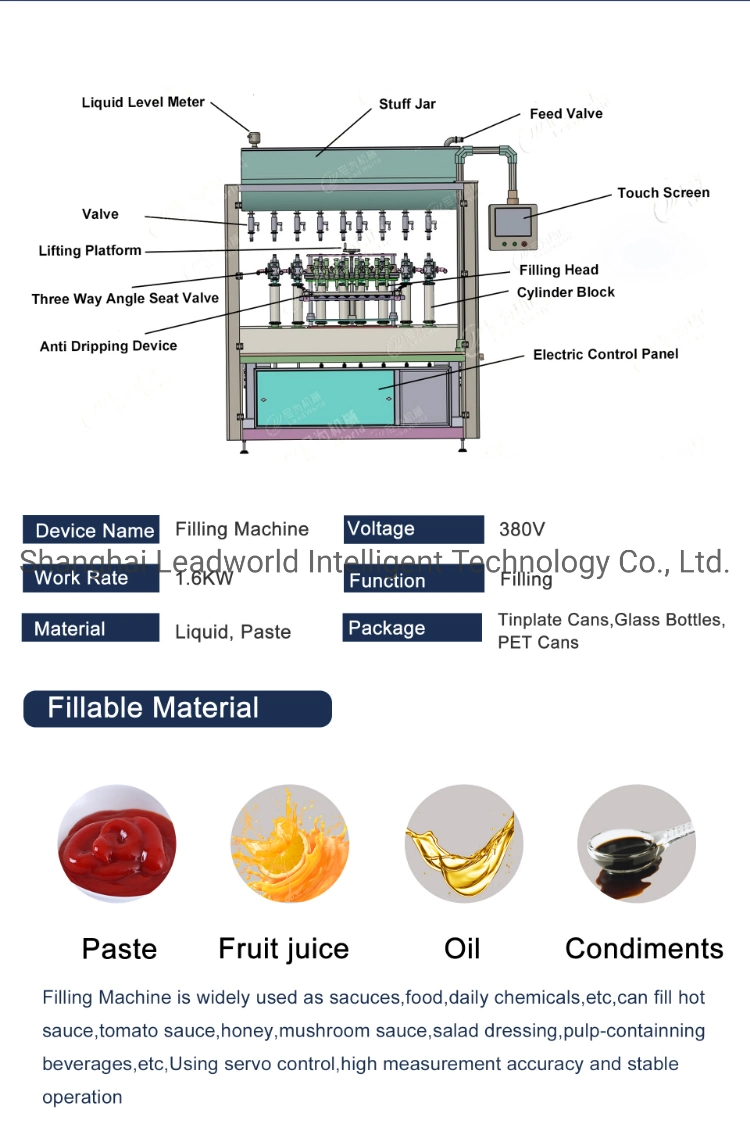

Filling Machine

Feed Cylinder Structure

Multi-Room Feeding

Dosing Device

Positive Displacement

Filling Principle

Precise Control of Servo Motor

Packaging Container Lifting Structure

Pneumatic Lifting

Structure

Linear

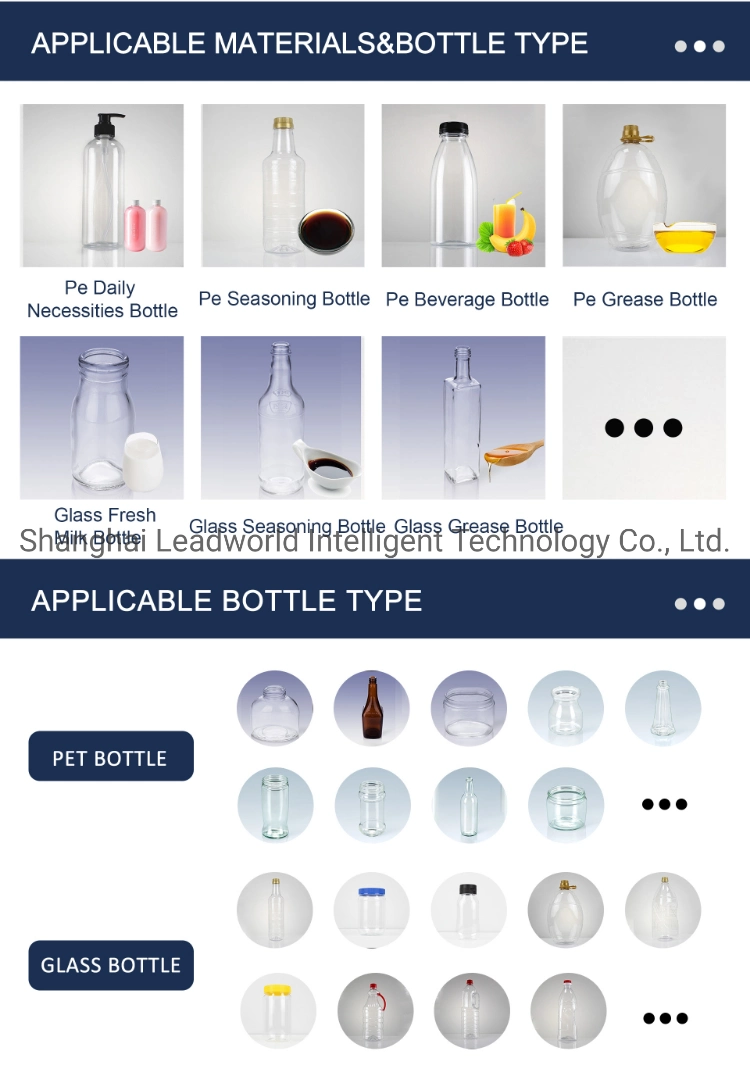

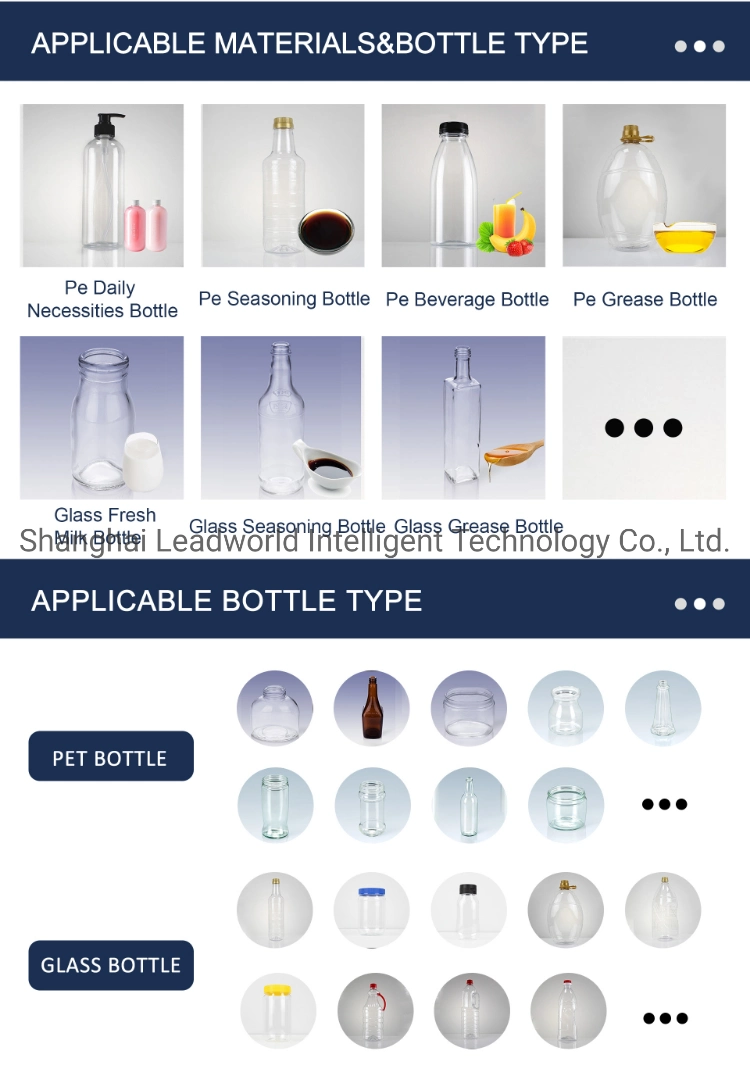

Packaging

Plastic, Tin, Glass

Packaging Material

Plastic, Tin, Glass

Product Name

Paste/Sauce/Jam Filling Machine

Material

Stainless Steel

Filling Volume

200-1000ml

Weight

500kg

Dimension(L*W*H)

250cm*102cm*225cm

Power Supply

3pH 380V 50/60Hz

Function

Automatic Filler

Feature

High Accouracy Filling Machine

Usage

Plastic, Tin, Glass

Brand Name

Lw

Application

All Kinds of Sauce

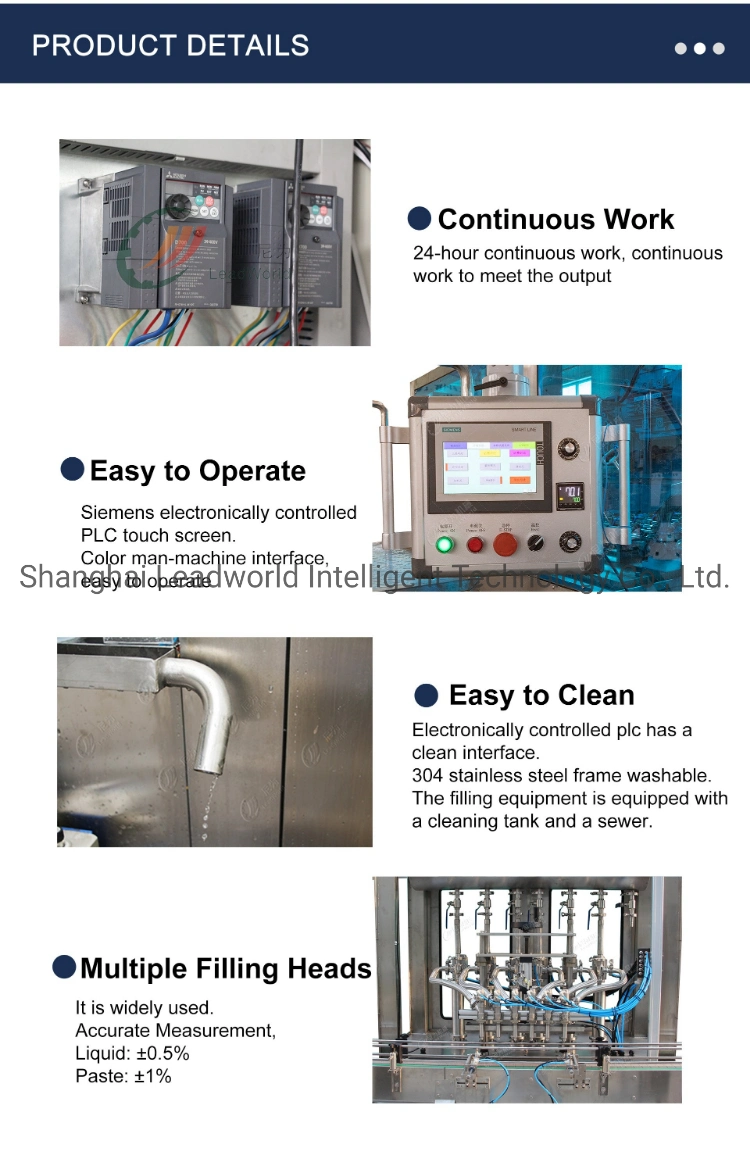

PLC

Siemens

Transport Package

Wooden Cases

Specification

220*102*225

Trademark

LW

Origin

Shanghai

HS Code

8422301090

Production Capacity

100 Piece Per Month

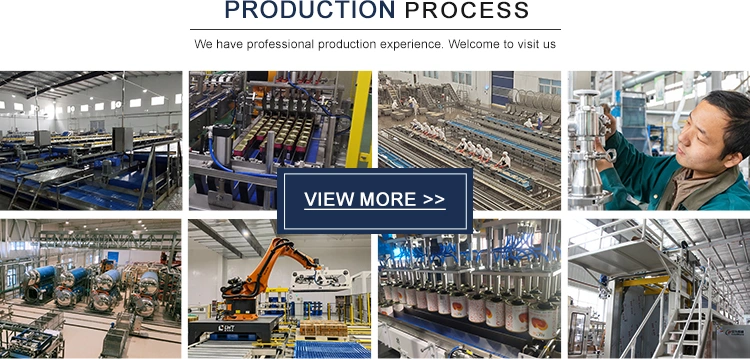

Product Description

Product Description

Filling Capping Packing MachineChocolate Sauce,Salad Dressing,Honey,Mayonnaise,Chili Sauce,Mushroom Sauce,

Juice Drink Tomato Ketchup Canned Filling Machine

Technical Parameters:

Accessories list:

Features:

About Us

About Us

About Us

FAQ

Q1:Are you manufacturer or trading company?

We are manufacture verified by ALIBABA and we have our own design team.

Q2:Where are you located? Is it convenient to visit you?

We are located in Shanghai. Traffic is very convenient.

Q3:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3.The electrical pneumatic components are from the world famous companies, such as Germany's Siemens, Japanese Panasonic etc.

4.We will do strict test running after the machine is finished.

5.Our machines are certified by CE,SGS,ISO.

Q4:Can you design the machine according to our requirements?

Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q5:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your worker if needed.

Q6: what we should know when you purchase the filling machine?

You should tell us what is your product you wanna fill? what is your filling type?filling the bottle,canned and so on.what is your speed requirement or how many quantity per minute you wanna fill?

Filling Capping Packing MachineChocolate Sauce,Salad Dressing,Honey,Mayonnaise,Chili Sauce,Mushroom Sauce,

Juice Drink Tomato Ketchup Canned Filling Machine

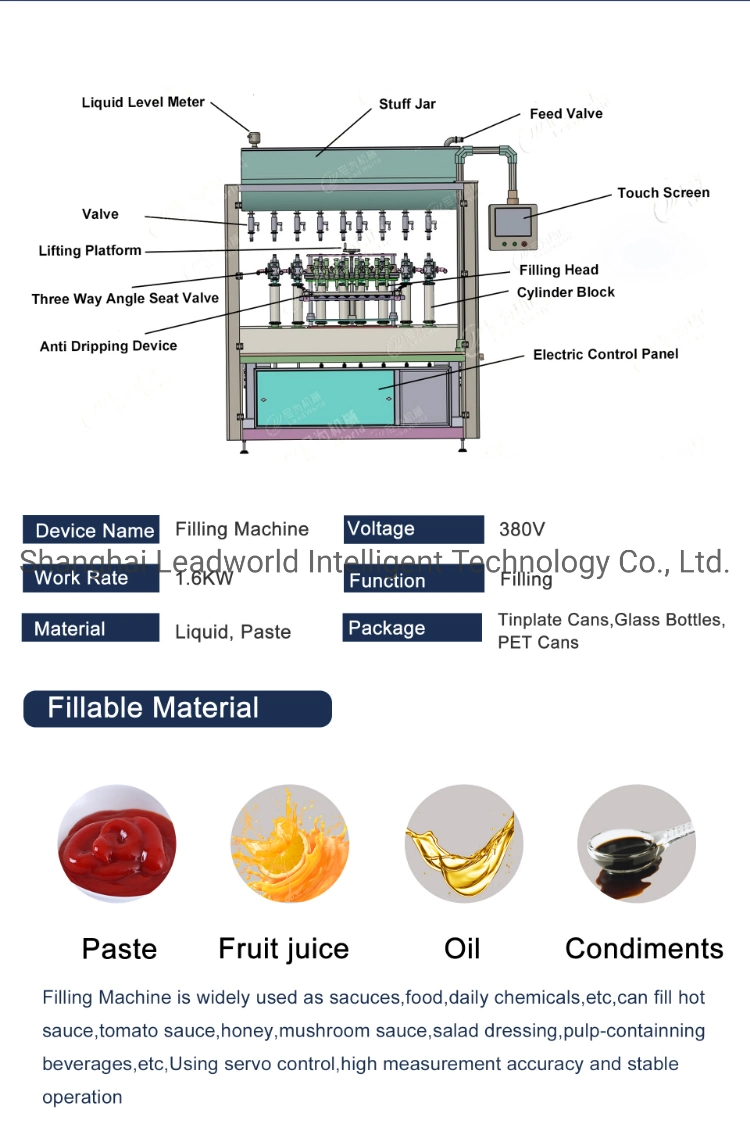

Filling Machine is widely used as sauces,foods etc,can fill hot sauce,tomato ketchup,honey,jam,mushroom sauce,mustard sauce,

pepper sauce,chili sauce,peanut butter,salad dressing,pulp-containing beverages and other liquid. Filling.

Note:

1. Welcome to my website!

2. Are you looking for Sauce/Paste Filling Machine?

3. Please Consult Us Immediately and we will help you at the first time!

Technical Parameters:

| Model | LW--4A | LW--6A | LW--8A | LW--10A | LW--12A |

| Filling Volume | 500ml can customize | 500ml can customize | 500ml can customize | 1000-2500ml can customize | 2500-5000ml can customize |

| Air Consumption | 120L/Min | 140L/Min | 160L/Min | 280L/Min | 300L/Min |

| Total Power | AC380V, 50/60HZ 1.4KW | AC380V, 50/60HZ 1.7KW | AC380V, 50/60HZ 2.1KW | AC380V, 50/60HZ 2.9KW | AC380V, 50/60HZ 3KW |

| Capacity | 0--1920 bottles/h 500ml bottle as an example | 1800-2520 bottles/h 500ml bottle as an example | 2400-3360 bottles/h 500ml bottle as an example | 3000-4200 bottles/h 500ml bottle as an example | 3600-5040 bottles/h 500ml bottle as an example |

| Filling Heads | 4 | 6 | 8 | 10 | 12 |

| Material | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

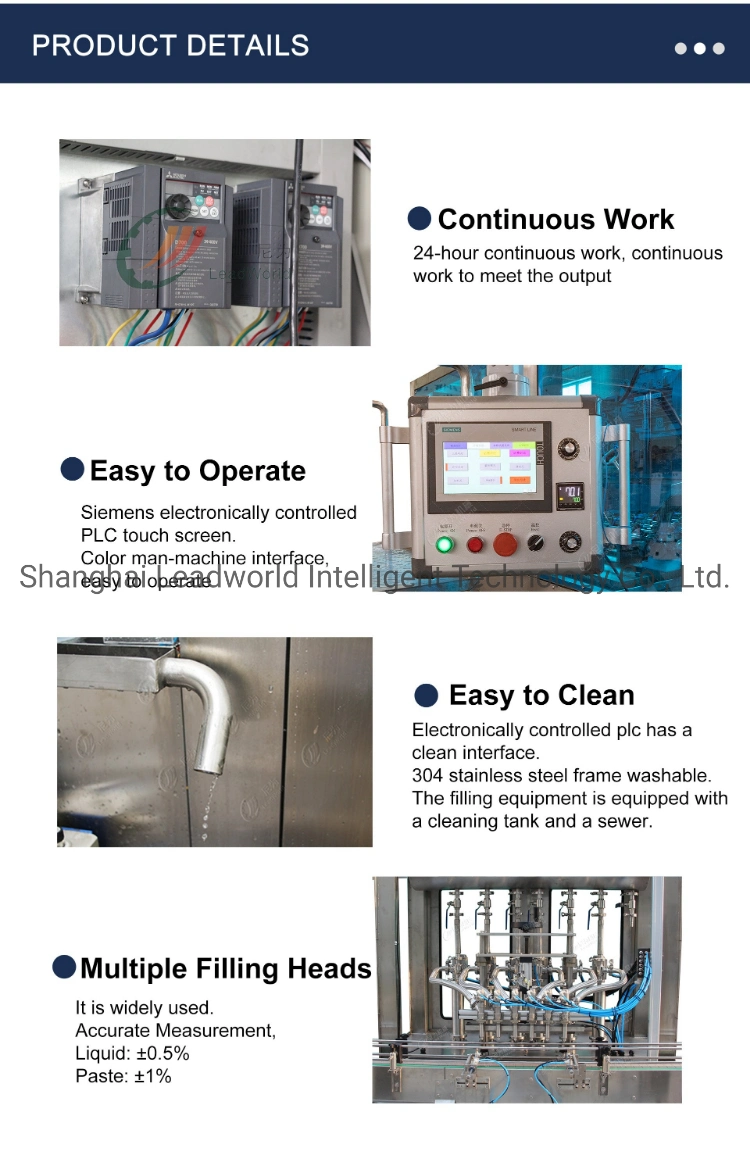

| Accessories name | Brand name |

| PLC | Siemens German |

| pneumatic element | AirTac Taiwan |

| amphenol connector | Weidmuller German |

| Bearing | IGUS German |

| Photoelectricity | KEYENCE Japan it is waterproof |

| Piston | Taiwan, heat-resistant, oil proof |

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame,Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

10.Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor

About Us

About Us

About Us

FAQ

Q1:Are you manufacturer or trading company?

We are manufacture verified by ALIBABA and we have our own design team.

Q2:Where are you located? Is it convenient to visit you?

We are located in Shanghai. Traffic is very convenient.

Q3:How can you guarantee quality?

1.We have completed working system and procedures and we follow them very strictly.

2.Our different worker is responsible for different working process, their work is confirmed,and will always operate this process, so very experienced.

3.The electrical pneumatic components are from the world famous companies, such as Germany's Siemens, Japanese Panasonic etc.

4.We will do strict test running after the machine is finished.

5.Our machines are certified by CE,SGS,ISO.

Q4:Can you design the machine according to our requirements?

Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q5:Can you offer overseas technical support?

Yes. We can send engineer to your company to set the machine and train your worker if needed.

Q6: what we should know when you purchase the filling machine?

You should tell us what is your product you wanna fill? what is your filling type?filling the bottle,canned and so on.what is your speed requirement or how many quantity per minute you wanna fill?

Quick Quotation, Please Consult Us