Basic Info.

Model NO.

HC-130G

Application

Cleaning, Detergent, Cosmetics, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning

Type

Filling and Sealing Machine

Forming Species

Bag Moulding

Forming Function

Filling, Seal

Driven Type

Electric

Material Type

Powder/Granule/Liquid/Sauce

Packaging

Bag

Packaging Material

Plastic

MOQ

1 Set

Material

SUS304

Voltage

220 V /380 V or Custom

Packaging Type

Premade Bag

Bag Feeding

Automatically Picking up

Suitable Material

Powder / Liquid/Sauce /Granules/Oil

Bags Type

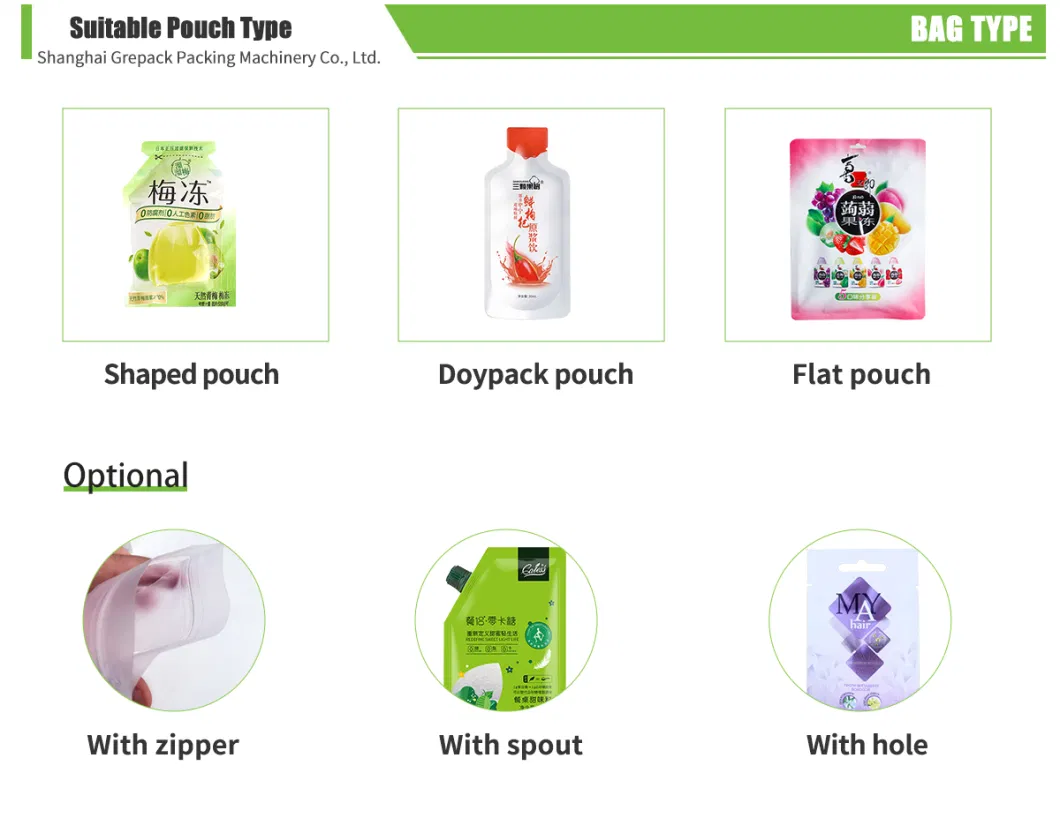

Stand up Pouch with Zipper or Spout, Flat Bag

Bag Size Range

Check The Size Range of Each Model Followed

Optional Function

Nitrogen Fill

Bag Open

Vacuum Open

Bag Open Detect

Vacuum or Sensors

Bag Open Rate

99%, No Bag Open, No Fill and Seal

Transport Package

Plywood Case

Specification

2160*1000*1400mm

Trademark

Grepack

Origin

China

HS Code

8422303090

Production Capacity

30 Per Month

Product Description

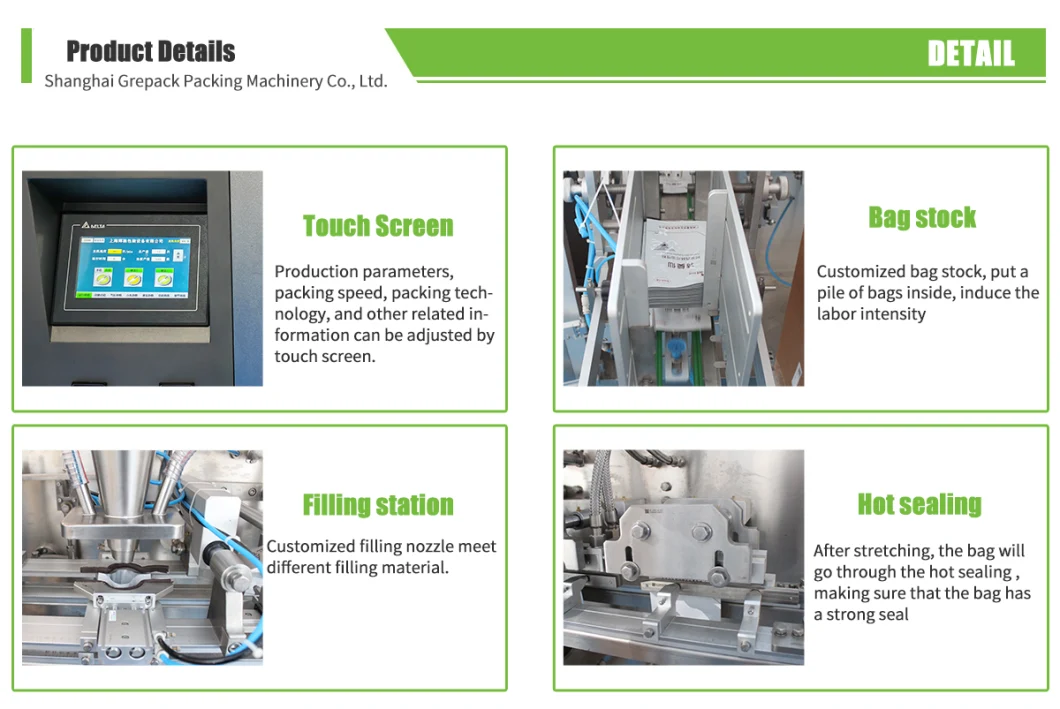

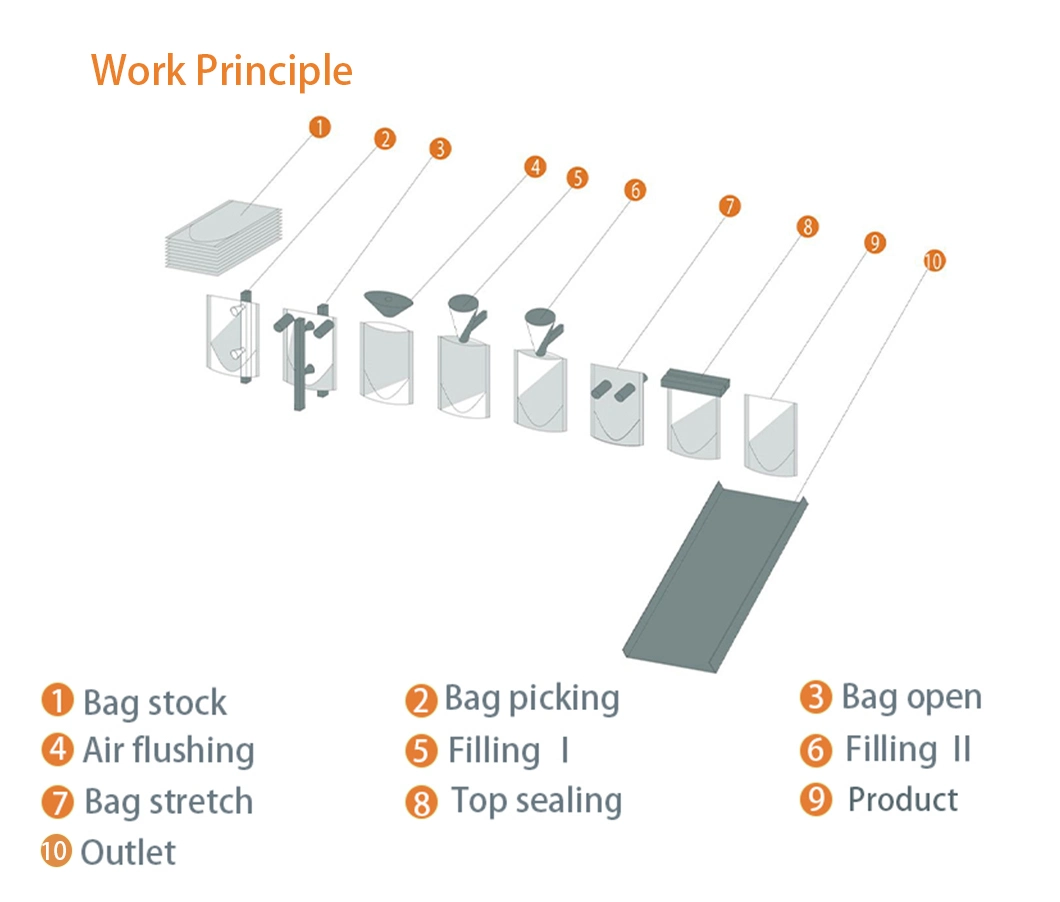

Horizontal Premade Pouch Packaging Machine.

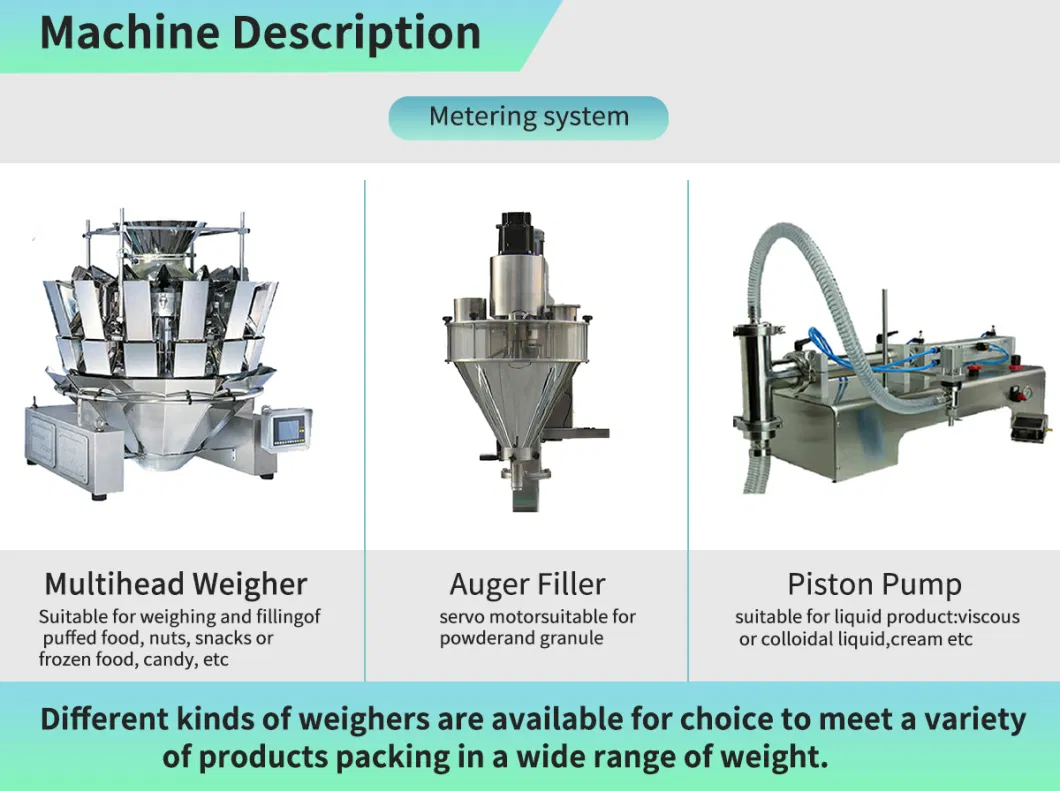

This series of horizontal premade bag packaging machines is a fully automatic premade bag packaging machine, which is suitable for users with many bag types, large packaging capacity, and small batches of products. It can meet the commonly used three-side sealing and four-side sealing and can realize the packaging of special bag types such as hanging hole bags, stand-up bags, special-shaped bags, etc. It is suitable for the packaging needs of various materials such as powder, granule, liquid, paste, and solid. Switching bag types is simple and fast; changing different metering devices can meet the packaging of different products.

This series of horizontal premade bag packaging machines is a fully automatic premade bag packaging machine, which is suitable for users with many bag types, large packaging capacity, and small batches of products. It can meet the commonly used three-side sealing and four-side sealing and can realize the packaging of special bag types such as hanging hole bags, stand-up bags, special-shaped bags, etc. It is suitable for the packaging needs of various materials such as powder, granule, liquid, paste, and solid. Switching bag types is simple and fast; changing different metering devices can meet the packaging of different products.

| Model | HC-180G | HC-210G | HC-240G |

| Pouch type | 3/4 side seal, doypack, standup pouch | ||

| Min pouch | 70×75mm | 100×120mm | 120×150mm |

| Max pouch | 180×225mm | 220×300mm | 240×350mm |

| Speed | < 60 pouch/ min | ||

| Filling range | max 500ml | max 1000ml | max 1500ml |

| Filling station | 1 | 1/2 | 1/2 |

| Power | 2kw | 3.5kw | |

| Voltage | 380V 3P 50Hz | ||

| Air consumption | 300L/min | 300L/min | 300L/min |

| Air pressure | 0.6-0.8 Mpa | 0.7MPa | 0.7MPa |

| Machine weight | 1000kg | 1000kg | 1500kg |

| Dimension | 2160×1000×1400mm | 2600×1000×1300mm | 2735×1500×1420mm |