Basic Info.

Model NO.

GK-H1100

Inching Speed

10m/Min

Thickness of Folded Box Max

20mm

Blank Width

1100mm

Length X Width X Height

16.5X1.7X1.9m

Net Weight

7.2t

Total Power

29kw

Compressed Air

6bar

Air Tank Capacity

60L

Transport Package

Wooden Pallets

Specification

XL-1100GS

Trademark

Gaoke

Origin

China

HS Code

8441309000

Production Capacity

30sets/Month

Product Description

Ruian Gaoke Machinery, is established in 2006. As a professional manufacturer, we not only do manufacturing, but also researching, marketing and offering after sales service. We supply quality equipments, effective and convenient solutions for cardboard box and corrugated box folding industry, printing and packaging industry.

We persist on business philosophy of technology and Innovation, casting quality and pursuit of excellence.

Product introduction:

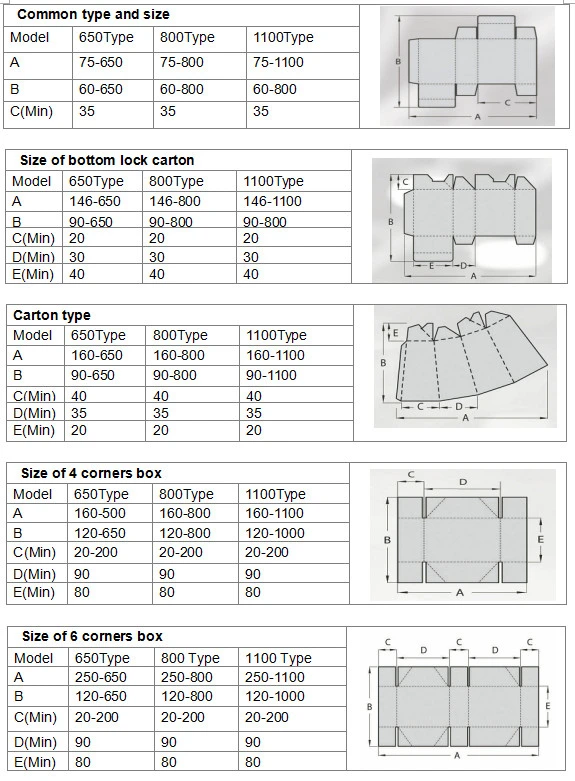

Four Six Corner High Efficiency Folder Gluer Machine(XL-650GS/800GS/1100GS)

Series GS folding gluing machine with 4/6 corner functon, each set is controlled by independent motor, adopts electrical regulating board, PLC, Imported electronic components, three plates track mode device. Aluminum plates are all chute structure, which is easy to add spare parts. The machine is especially designed for all kinds of 4/6 corner cardboard or corrugated packaging boxes, which can meet to all kinds of requirements of automatic packaging area.

Main Technical Parameters

| GS series | 650GS | 800GS | 1100GS |

| Processed Materials | |||

| Carton board max. | 650 mm | 800 mm | 1100 mm |

| Corrugated flute type | A, B, E | A, B, E | A, B, E |

| Capability | |||

| Speed max. | 400 m/min | 400 m/min | 400 m/min |

| Inching speed | 10 m/min | 10 m/min | 10 m/min |

| Thickness of folded box max. | 12 mm | 20 mm | 20 mm |

| Blank width | 650 mm | 800 mm | 1100 mm |

| Electrical connected load | 12 kW | 15 kW | 15 kW |

| Compressed air | 6 bar | 6 bar | 6 bar |

| Air compressor capacity | 10 m³/h | 10 m³/h | 10 m³/h |

| Air tank capacity | 60 L | 60 L | 60 L |

| Dimensions & weight | |||

| Length*Width*Height | 12*1.4*1.8m | 16.5 *1.4*1.8m | 16.5*1.7*1.9m |

| Net Weight | 5T | 6.6T | 7.6 T |